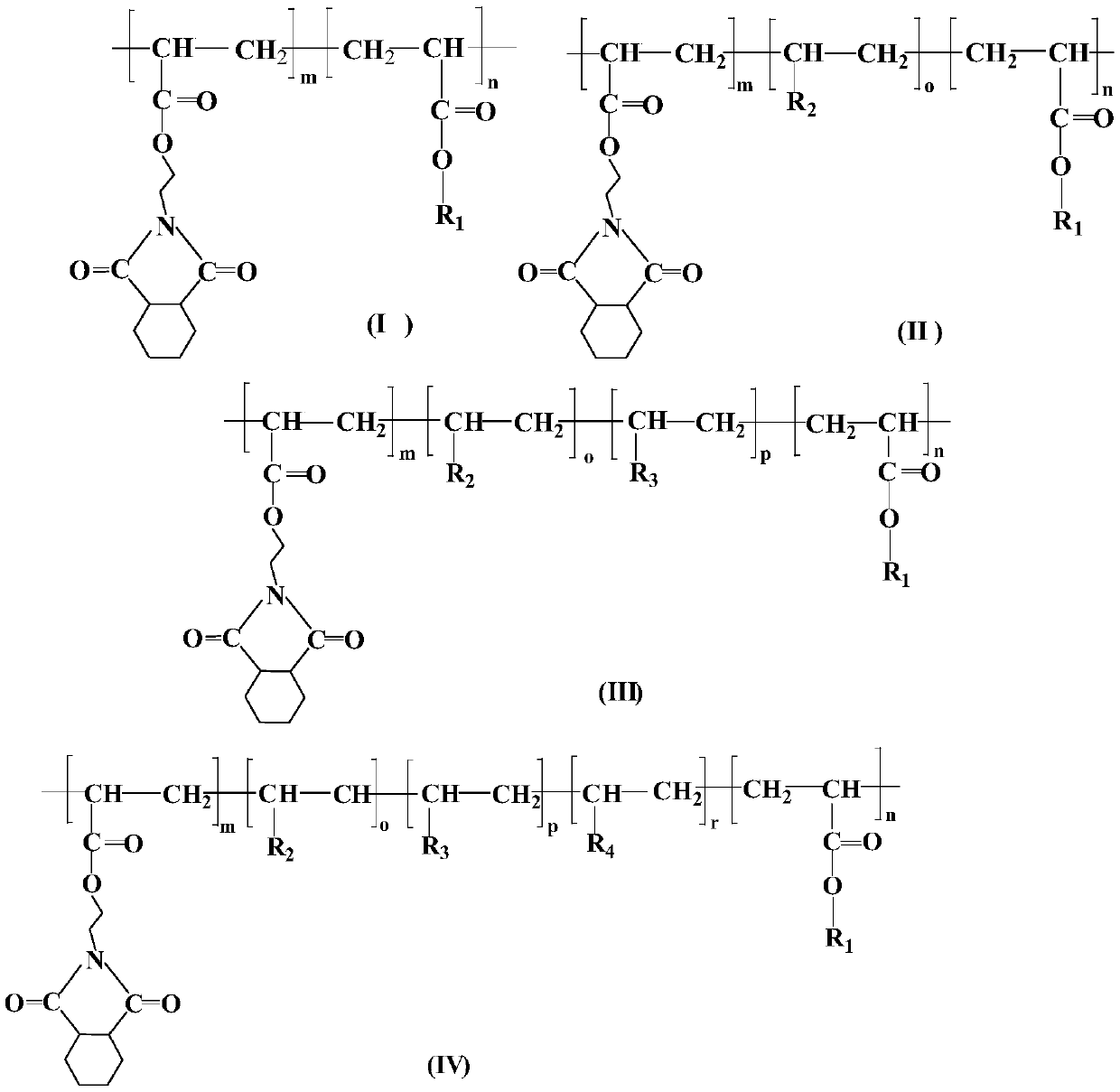

A photosensitive imaging composition comprising cyclohexaneamide monofunctional acrylate copolymer

A cyclohexane amide monofunctional, imaging composition technology, applied in the direction of photosensitive materials used in optomechanical equipment, etc., can solve the problems of reducing the printing resistance of the plate, insufficient dot protection, and reducing the sensitivity of the plate, achieving improved Alcohol resistance and printing resistance, inhibition of lateral dissolution rate, and effect of improving the quality of plate dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of lithographic plates

[0037] (1) Preparation of aluminum plate base:

[0038] An aluminum plate with a thickness of 0.28mm is subjected to degreasing treatment for 40 seconds in a 7wt% sodium hydroxide aqueous solution at a temperature of 55°C. Use sine wave alternating current for electrolytic treatment, 50HZ alternating current, current 50A / dm 2 , the electrolysis time is 60 seconds, control Ra=0.3-0.6um, preferably 0.4-0.6um, Rz (H) The value is 2 to 3 μm, then at 60°C, remove slag in 50wt% sodium hydroxide aqueous solution for 10 seconds, and then at 25°C with a current density of 5A / d㎡ and a concentration of 20wt% sulfuric acid Treat in solution for 40 seconds, control oxide film = 2.5-3.5g / m 2 . Finally, at 60 °C with NaH 2 PO 4 -NaF solution is sealed for 30 seconds to obtain an aluminum base suitable for a lithographic printing plate.

[0039] (2) The photosensitive imaging composition was formulated into a heat-sensitive CTP coating soluti...

Embodiment 2

[0055] The sample preparation method is the same as in Example 1, and the content of each component in the photosensitive imaging composition is as shown in Table 4:

[0056] Table four

[0057] BTB-225 resin (Weihai Tiancheng Chemical Co., Ltd.) 0.193g PD-1646 resin (HEXION, USA) 0.579g Cyclohexaneamide monofunctional acrylate copolymer (m:n=5:1) 0.15g Infrared absorbing dye LC-01 (Honywell company) 0.02g Alkylbenzenesulfonic acid 0.04g methyl violet 0.018g

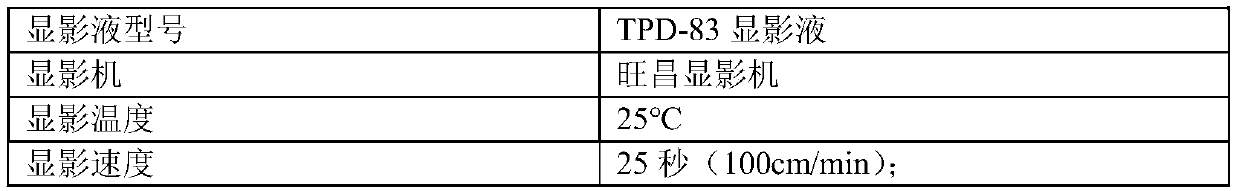

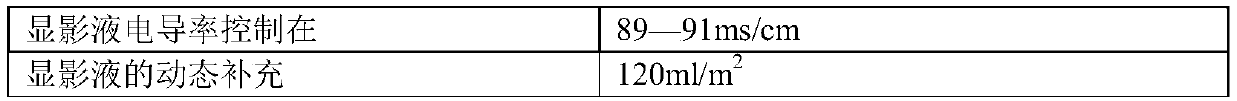

[0058] The above-mentioned photosensitive lithographic plate is installed on the plate-making machine for exposure. Use alkaline developer TPD-83 (manufactured by Lucky Huaguang Printing Technology Co., Ltd.) to develop at 25°C for 25 seconds. The sensitivity and development latitude are shown in Table 14.

Embodiment 3

[0060] The sample preparation method is the same as in Example 1, and the content of each component in the photosensitive imaging composition is as shown in Table 5:

[0061] Table five

[0062] BTB-225 resin (Weihai Tiancheng Chemical Co., Ltd.) 0.437g PD-1646 resin (HEXION, USA) 0.28 Cyclohexaneamide monofunctional acrylate copolymer (m:n=5:1) 0.20g Infrared absorbing dye LC-01 (Honywell company) 0.02g 3,4,5-Trimethoxybenzoic acid 0.04g Ethyl Violet 0.02g

[0063] The above-mentioned photosensitive lithographic plate is installed on the plate-making machine for exposure. Use alkaline developer TPD-83 (manufactured by Lucky Huaguang Printing Technology Co., Ltd.) to develop at 25°C for 30 seconds. The sensitivity and development latitude are shown in Table 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com