Concentrated feed capable of improving lactating performance of dairy cows and lowering nitrogen excretion

A technology of concentrated feed and nitrogen excretion, which is applied in the field of feed in animal husbandry technology, can solve problems such as pollution and neglect, and achieve the effect of improving utilization rate, milk fat rate and milk protein rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Select 20 Holstein dairy cows with good body condition, age, weight, average daily milk yield (30.5±2.5Kg), milk composition and lactation period (55±19.5d), and divide them into two groups, 10 in each group. Each head of the control group and the test group was fed 12Kg of basic concentrated feed every day, and each head of the test group was added with cinnamaldehyde 15g and 30g of rumen-passed methionine every day, and the control group did not add; the basic concentrated feed was mixed according to the following ratio and stirred evenly: Corn 48%, bran 21%, cottonseed meal 10%, soybean meal 16%, salt 1%, baking soda 1.1%, magnesium oxide 0.5%, stone powder 1%, trace element premix 1.1%, vitamin AD 3 Powder 0.3%.

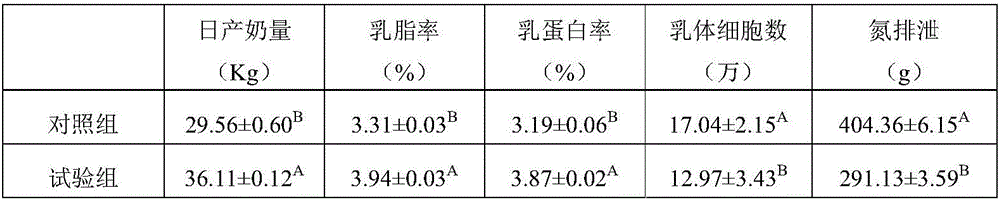

[0020] The two groups were fed with exactly the same roughage: 5Kg of alfalfa hay, 28Kg of whole plant corn silage and 1Kg of dry apple pomace per head per day. The test results are shown in Table 1.

[0021] Table 1 Effects of cinnamaldehyde and rumen-p...

Embodiment 2

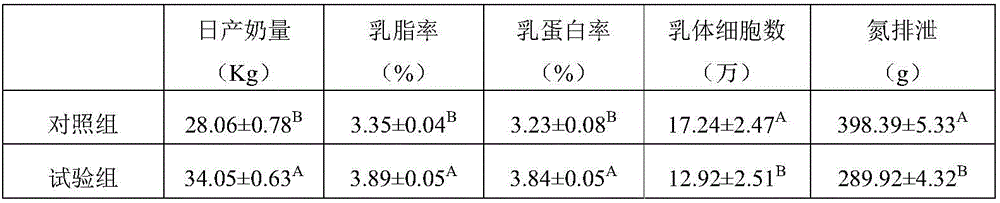

[0026] Select 30 Holstein dairy cows with good body condition, age, weight, average daily milk yield (28.6±2.2Kg), milk composition and lactation period (60±15.3d), and divide them into two groups, 15 in each group. Each head of the control group and the test group was fed 11Kg of basic concentrate feed every day, and each head of the test group added cinnamaldehyde 16g and rumen-passed methionine 25g every day, and the control group did not add; the base concentrate feed was mixed according to the following ratio and stirred evenly: Corn 47%, bran 20%, cottonseed meal 12%, soybean meal 16%, salt 1%, baking soda 1.2%, magnesium oxide 0.5%, stone powder 1%, trace element premix 1.1%, vitamin AD 3 Powder 0.2%.

[0027] The roughage fed to the two groups was exactly the same: 4Kg of alfalfa hay, 30Kg of whole plant corn silage and 1Kg of dry apple pomace were fed per head per day. The test results are shown in Table 2.

[0028] Table 2 Effects of cinnamaldehyde and rumen-passed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com