A kind of cod fat stick and preparation method thereof

A technology for fat and cod, which is applied to the field of cod fat strips and their preparation, can solve problems such as waste of fat strips, and achieve the effects of increasing profit margins, improving texture properties, and being tightly combined.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

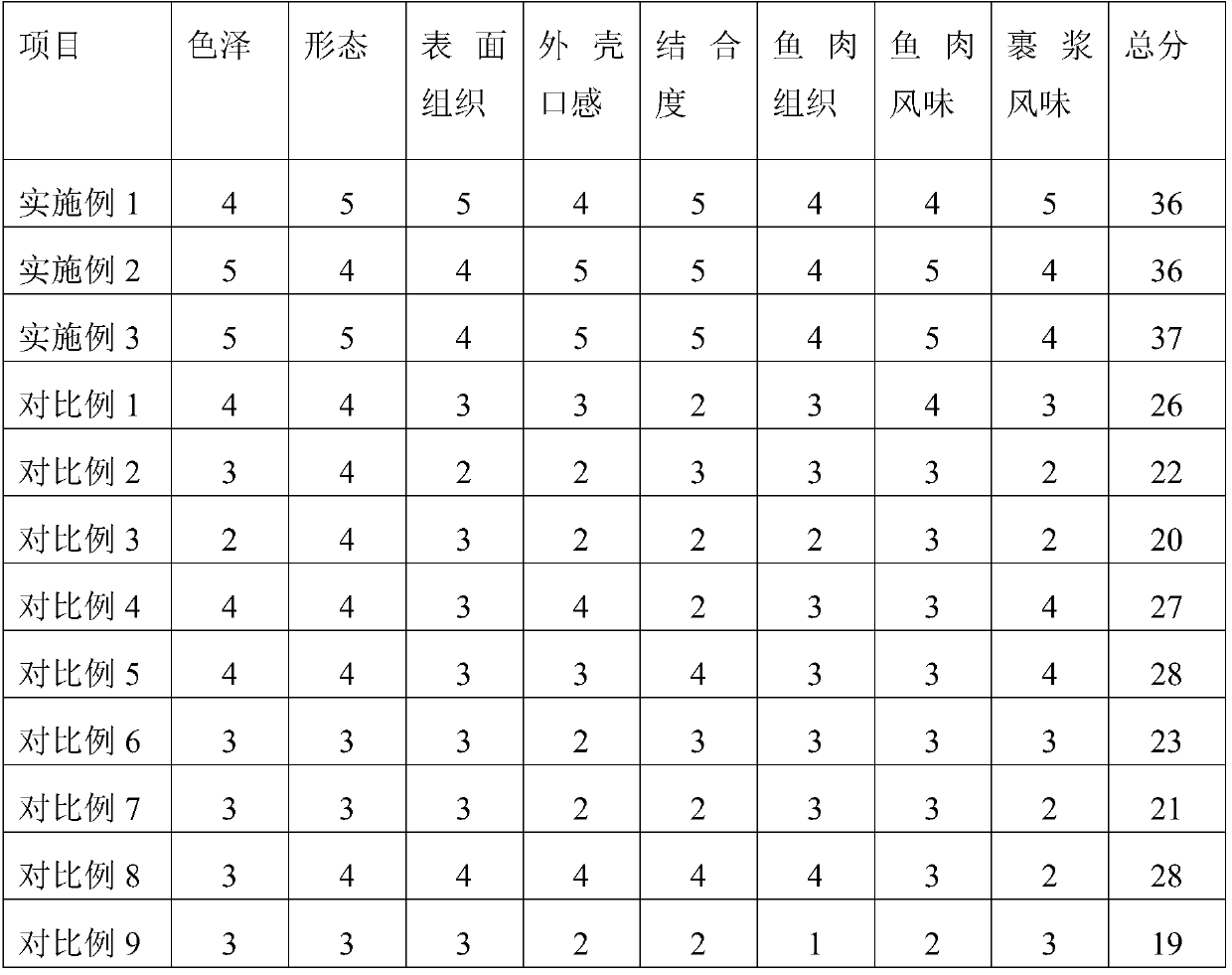

Embodiment 1

[0036] A cod fish fat bar, the component content is: fat bar core material 52wt%, pre-coated powder 5wt%, slurry 39wt%, palm oil 4wt%, and prepared according to the following method:

[0037] S1. Collect fat strips from the cod production line, select fat strips with moderate meat volume, wash away congestion, black film and other impurities, and chop them into 0.5cm×0.5cm×0.5cm~1cm×1cm×1cm pieces with a chopper meat;

[0038] S2: Recombination and molding of fish strips with TG enzyme: 100 parts by weight of fat strips of minced meat, 1 part by weight of transglutaminase, 1 part by weight of soybean protein isolate, and 9 parts of water are stirred evenly, and the temperature is 4~8℃. Place it for 3 hours, and then use a rectangular parallelepiped mold of 12cm×1cm×1cm to shape, with a weight range of 15-25g;

[0039] S3. Quick-freeze the fish sticks to a temperature below -5℃;

[0040] S4. Fish sticks wrapped in pre-coated powder;

[0041] S5. Blending Tangyang flour. The composition...

Embodiment 2

[0049] A cod fish fat bar, the component content is: fat bar core material 55wt%, pre-coated powder 4wt%, slurry 37wt%, palm oil 3wt%, and prepared according to the following method:

[0050] S1. Collect the fat strips from the cod production line, select the fat strips with a moderate amount of meat, wash away the congestion, black film and other impurities, and chop them into 0.5cm×0.5cm×0.5cm~1cm×1cm×1cm pieces with a chopper meat;

[0051] S2: Recombination and molding of fish strips with TG enzyme: 80 parts by weight of fat strips of minced meat, 3 parts by weight of transglutaminase, 3 parts by weight of soy protein isolate, and 10 parts of water are stirred evenly at 4~8℃. Place it for 4 hours, and then use a rectangular parallelepiped mold of 12cm×1cm×1cm to shape, with a weight range of 15-25g;

[0052] S3. Quickly freeze the fish sticks to a temperature below -5℃;

[0053] S4. Fish sticks wrapped in pre-coated powder;

[0054] S5. Blending Tangyang powder. The composition of...

Embodiment 3

[0062] A cod fish fat bar, the component content is: fat bar core material 49wt%, pre-coated powder 6wt%, slurry 40wt%, palm oil 5wt%, and prepared according to the following method:

[0063] S1. Collect the fat strips from the cod production line, select the fat strips with a moderate amount of meat, wash away the congestion, black film and other impurities, and chop them into 0.5cm×0.5cm×0.5cm~1cm×1cm×1cm pieces with a chopper meat;

[0064] S2: Recombination and molding of fish strips with TG enzyme: 90 parts by weight of fat strips of minced meat, 2 parts by weight of transglutaminase, 2 parts by weight of soy protein isolate, and 9 parts of water are stirred evenly, at 4~8℃ Place it for 3 hours, and then use a rectangular parallelepiped mold of 12cm×1cm×1cm to shape, with a weight range of 15-25g;

[0065] S3. Quickly freeze the fish sticks to a temperature below -5℃;

[0066] S4. Fish sticks wrapped in pre-coated powder;

[0067] S5. Blending Tangyang flour. The composition of T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com