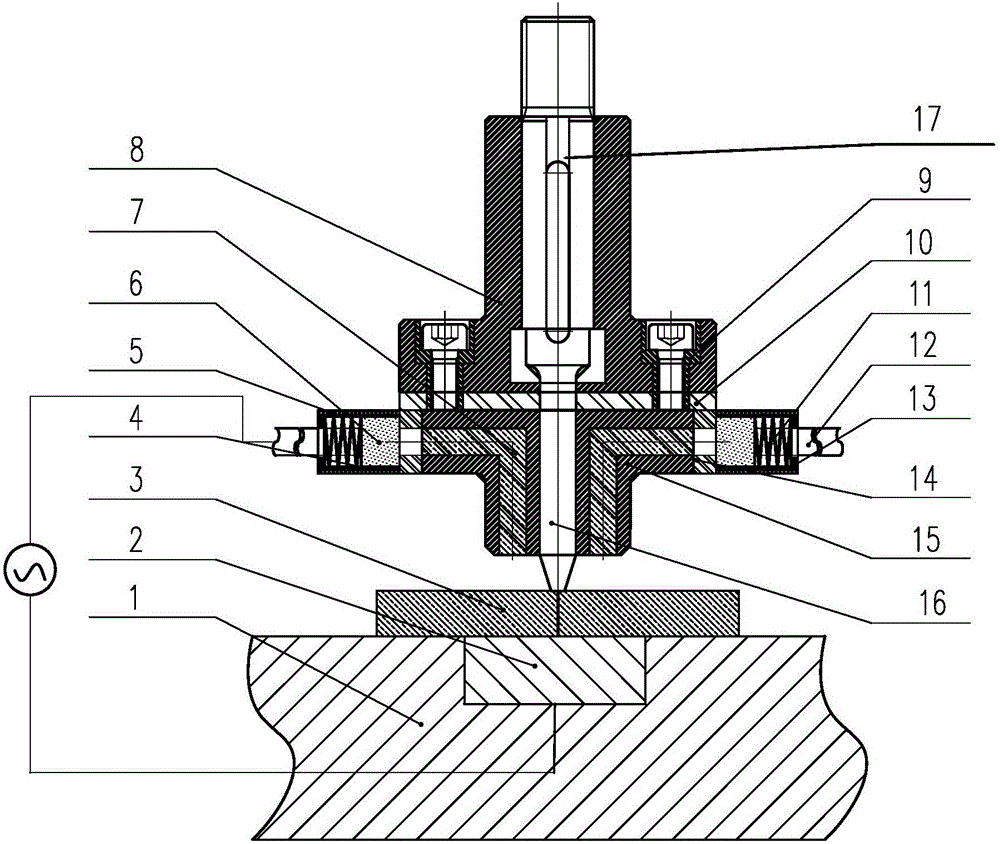

Device and method for performing friction stir welding on thick plate without keyhole formation

A friction stir welding and keyhole technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem that the root of the weld is difficult to soften and flow plastically, the thickness of the weldable workpiece is limited, and it is difficult to reach the root of the weld, etc. problems, to achieve the effect of improving friction stir welding efficiency and product quality, low cost, and high withdrawal precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

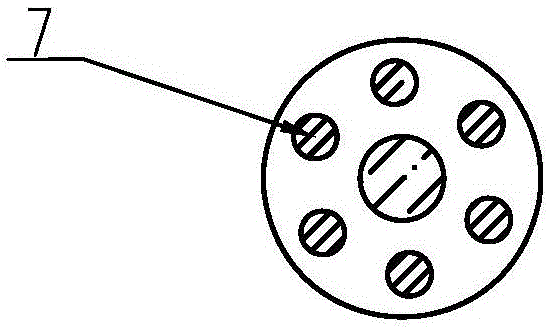

Method used

Image

Examples

Embodiment

[0037] The 20mm thick AA2024-T3 aluminum alloy cold rolled plate is butted. The traveling speed is 200mm / min, the rotating speed is 1100r / min, the shoulder reduction is 0.2mm, and two groups of friction stir welding are performed without current and with current intensity of 60A. The root temperature of the current sample during welding is 62°C higher than that of the non-current sample.

[0038] Butt jointing of 20mm thick AA6082-T6 aluminum alloy cold-rolled plates. The travel speed is 200mm / min, the rotation speed is 1200r / min, the shoulder reduction is 0.2mm, and two groups of friction stir welding are performed without current and with current intensity of 90A. The root temperature of the current sample during welding is 53°C higher than that of the non-current sample.

[0039] The 20mm thick AA7075-T6 aluminum alloy cold-rolled plate is butted. The travel speed is 200mm / min, the rotation speed is 1200r / min, the shoulder reduction is 0.2mm, and two groups of friction s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com