Boron nitride nanosheet powder and macro-quantity preparation method thereof

A technology of nanosheets and boron nitride, applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve the problems of small size, high cost, and low efficiency of nanosheets, and achieve mass production and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In a typical implementation of the present invention, a method for the macro-preparation of boron nitride nanosheet powder comprises the following steps:

[0034] (1) Thoroughly mix the boron source and the nitrogen source precursor, heat to 1100-1500°C (preferably 1100-1400°C, especially preferably 1200-1300°C) in an atmosphere containing ammonia gas and keep it warm for 0.5-4h, Cool down to room temperature under the protection of nitrogen or argon to obtain a white crude product.

[0035] (2) pickling, filtering and drying the crude product obtained in step (1) to obtain boron nitride nanosheet powder with a purity of more than 99%.

[0036] With the aforementioned method, according to the amount of the precursor and the volume of the equipment, the output of a single batch can reach more than gram level. Under optimal synthesis conditions, 30-35 g of boron nitride nanosheets can be obtained from 100 g of reactants, and the net yield is as high as 90%.

[0037] Whe...

Embodiment 1

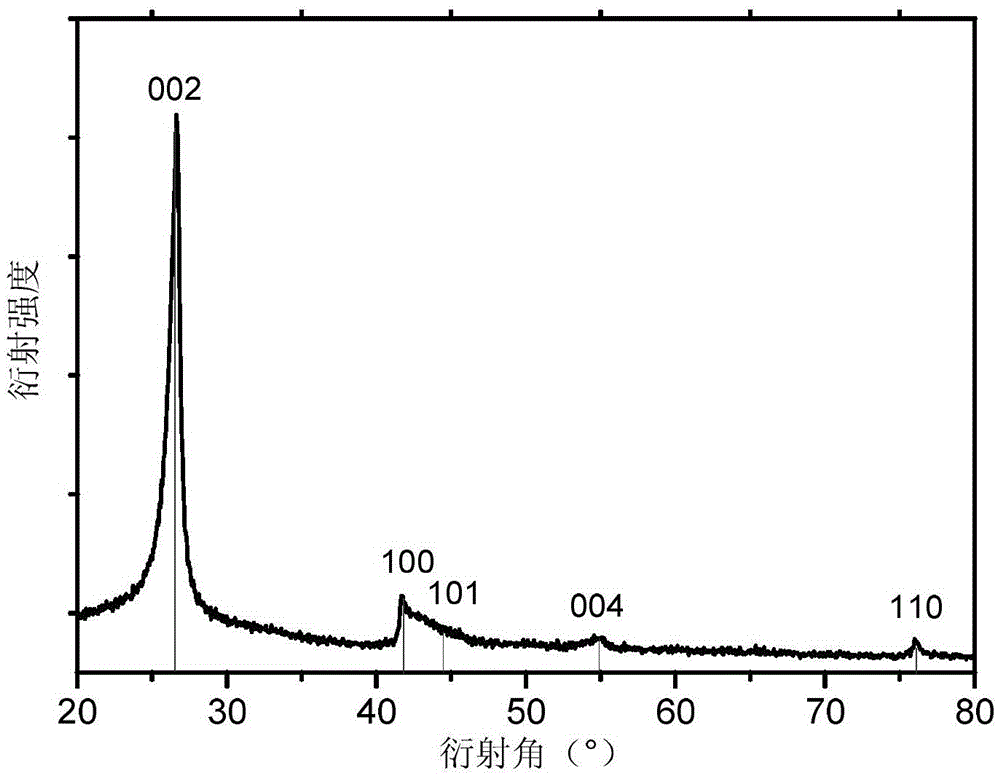

[0048] Example 1 will B 2 o 3 and Mg 3 N 2 Mix well at a molar ratio of 2:1, take 1g and place it in an open alumina crucible, then put it into a tube furnace, and vacuum to 10 -3 Pa, 200 standard milliliters per minute (sccm) of NH 3 , heating up to 1300°C. Turn off NH after 180min constant temperature reaction at 1300°C 3 , into 500sccm N 2 , at N 2 The temperature was cooled to room temperature in the atmosphere, and the crude product was obtained. Then the obtained product is ultrasonically pickled with 3 mol / L nitric acid for 5 hours, filtered and dried to obtain boron nitride nanosheet powder with a purity of more than 99%. figure 1 The physical photo of the unacid-washed crude product of BN nanosheets prepared for this example. figure 2 It is the physical photo of the BN nanosheet (boron nitride nanosheet, BN nanosheet, BNNS for short) after purification in this embodiment. In this example, a yield of 90% can be obtained. image 3 This is the XRD pattern of ...

Embodiment 2

[0049] Example 2 will B 2 o 3 and Mg 3 N 2 Mix thoroughly at a molar ratio of 1:1, take some and place them in an open alumina crucible, and then put them into a tube furnace. The furnace tube was purged of air by blowing 1000 standard milliliters per minute (sccm) of Ar. Then 200sccm Ar and 200sccm NH 3 The temperature was raised to 1300°C. Turn off the NH after reacting at a constant temperature of 1300°C for 60 minutes 3 , 500 sccm of Ar was introduced to cool down to room temperature, and the crucible was taken out to obtain a crude product. Then the obtained product is ultrasonically pickled with 3 mol / L nitric acid for 10 h, filtered and dried to obtain boron nitride nanosheet powder with a purity of more than 99%. Figure 5 This is the SEM image of the BN nanosheets obtained in this example, and scaly BN nanosheets can be observed. Image 6 For the Raman spectrum of the BNNS that this embodiment obtains, by 1367.9cm - 1 The peak can be judged as hexagonal stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com