A high-efficiency combined treatment agent, preparation and advanced pretreatment method of coking wastewater

A treatment method and technology for coking wastewater, applied in chemical instruments and methods, metallurgical wastewater treatment, water/sewage treatment, etc., to achieve the effects of improved effect, stable treatment effect and short treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

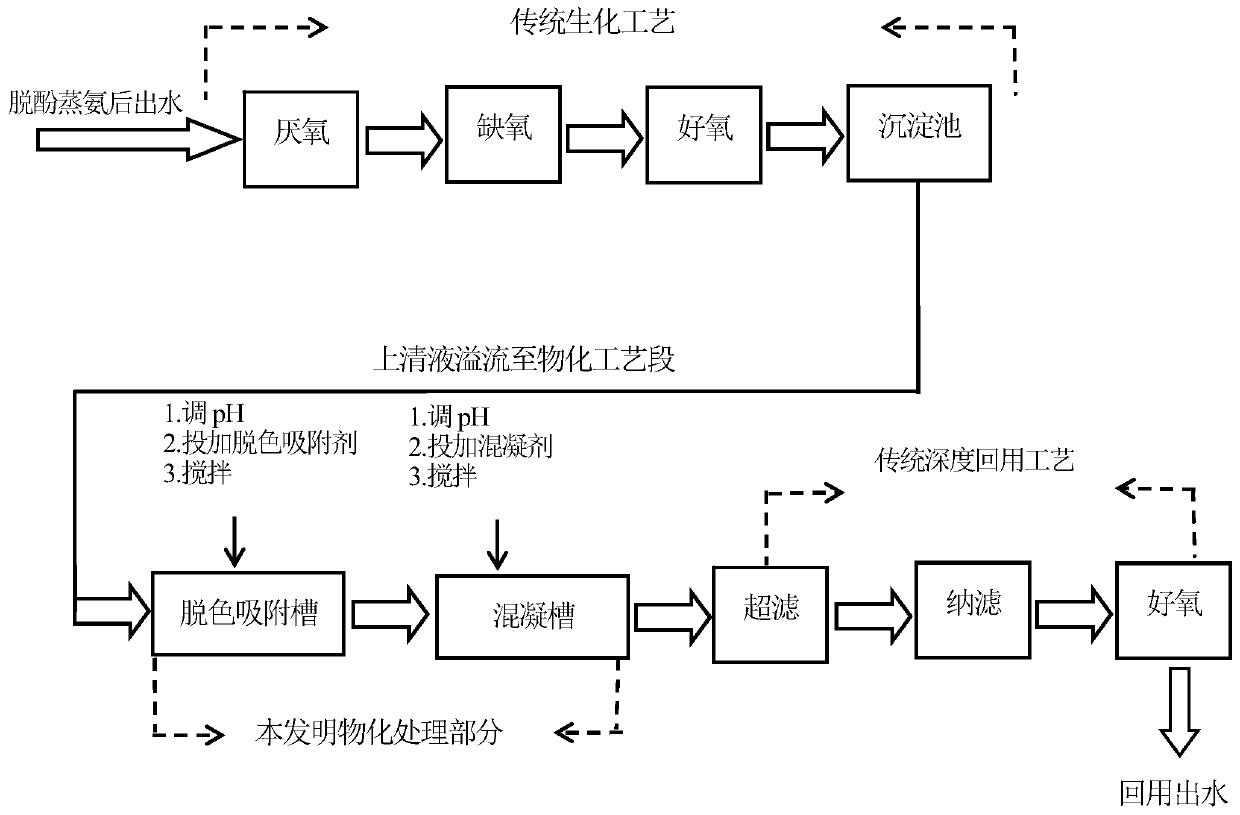

Method used

Image

Examples

Embodiment 1

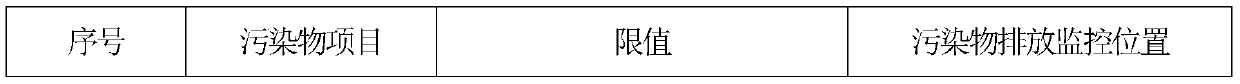

[0049] 1. The biochemical effluent (raw water) of coking wastewater is pumped to the decolorization adsorption tank through the raw water pump. Raw water quality: Raw water quality: pH is 8, COD is 350mg / l, oil is 11mg / l, suspended matter is 55mg / l, T-CN is 5mg / l, water temperature is 30°C;

[0050] 2. Inject sulfuric acid into the tank through a quantitative pump, and the pH value is 6;

[0051] 3. Dosing the decolorizing adsorbent into the tank through the powder dosing device, the dosing concentration is 300ppm; activated carbon: specific surface area 900m 2 / ml, pore size 10000nm, iodine adsorption value 850mg / g, ash content 5%; slag powder A: particle size 350nm;

[0052] The decolorization and cyanide removal agent includes activated carbon: 50%, slag powder A: 50%.

[0053] 4. Stir with a mixer to fully mix the medicine and water, the hydraulic retention time is 30mins, and the effluent mixture overflows to the coagulation tank;

[0054] 5. After decolorization and a...

Embodiment 2

[0057] 1. The biochemical effluent (raw water) of coking wastewater is pumped to the decolorization adsorption tank through the raw water pump. Raw water quality: Raw water quality: pH is 7.8, COD is 310mg / l, oil is 10mg / l, suspended matter is 40mg / l, T-CN is 6.1mg / l, water temperature is 28°C;

[0058] 2. Inject sulfuric acid into the tank through a quantitative pump, and the pH value is 6;

[0059] 3. Dosing the decolorizing adsorbent into the tank through the powder dosing device, the dosing concentration is 310ppm; activated carbon: specific surface area 1200m 2 / ml, pore size 9000nm, iodine adsorption value 950mg / g, ash content 5%; slag powder A: particle size 200nm;

[0060] The decolorization and cyanide removal agent includes activated carbon: 70%, slag powder A: 30%.

[0061] 4. Stir with a mixer to fully mix the medicine and water, the hydraulic retention time is 30mins, and the effluent mixture overflows to the coagulation tank;

[0062] 5. After decolorization a...

Embodiment 3

[0065] 1. The biochemical effluent (raw water) of coking wastewater is pumped to the decolorization adsorption tank through the raw water pump. Raw water quality: Raw water quality: pH is 7.5, COD is 280mg / l, oil is 9.5mg / l, suspended matter is 54mg / l, T-CN is 5.8mg / l, water temperature is 30°C;

[0066] 2. Inject sulfuric acid into the tank through a quantitative pump, and the pH value is 6;

[0067] 3. Add the decolorizing adsorbent to the tank through the powder dosing device, and the dosing concentration is 320ppm;

[0068] 4. Stir with a mixer to fully mix the medicine and water, the hydraulic retention time is 30mins, and the effluent mixture overflows to the coagulation tank;

[0069] 5. After decolorization and adsorption, the effluent enters the coagulation tank through the overflow. In the tank, the pH is first adjusted to 8 through the processing of industrial liquid alkali, and the coagulant is injected into the tank through the quantitative dosing pump. The dosin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com