Application of a hydrogen matrix biofilm reactor in removing bromate in drinking water

A biofilm reactor and drinking water technology, applied in biological water/sewage treatment, water pollutants, chemical instruments and methods, etc., can solve the problems of lack of organic nutrients and obstacles to the application of biotechnology, and achieve high gas utilization rate, The effect of simple, convenient, safe and efficient removal of membrane components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

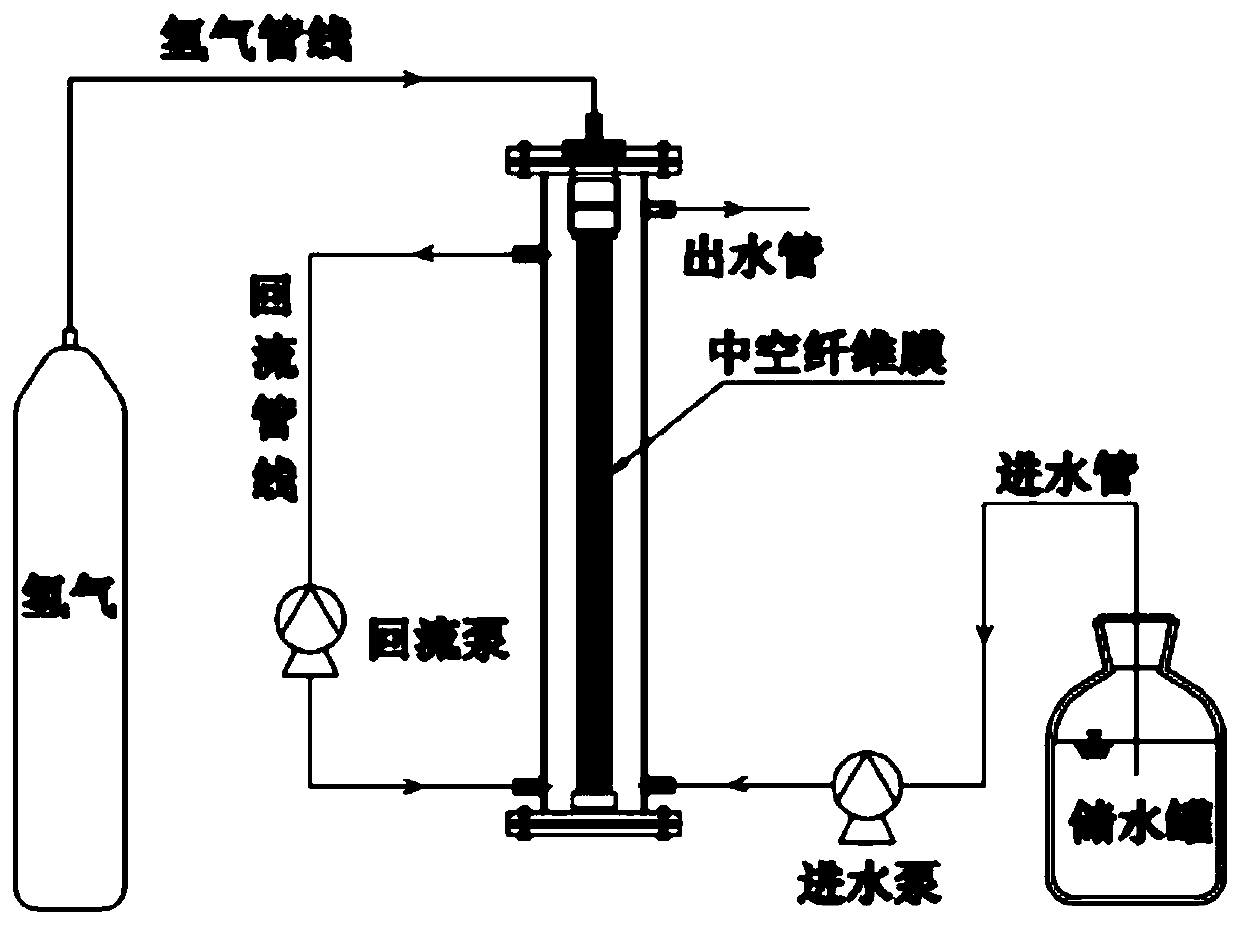

Method used

Image

Examples

Embodiment 1

[0072] Prepare simulated water for acclimation:

[0073] NaHCO 3 as an inorganic carbon source; NaNO 3 It is an inorganic nitrogen source; prepare a phosphate buffer (Na 2 HPO 4 +KH 2 PO 4 ), and adjust the pH of the buffer to 7.0; the specific components and concentrations of the simulated water for acclimation are shown in Table 1.

[0074] Table 1 Simulated water composition table for domestication

[0075] Macronutrients Concentration / (mg / L) trace elements Concentration / (mg / L) NaNO 3

60 ZnSO 4 ·7H 2 o

0.013 K H 2 PO 4

128 h 3 BO 3

0.038 MgSO 4 ·7H 2 o

200 CuCl 2 2H 2 o

0.001 FeSO 4 ·7H 2 o

1 Na 2 MoO 4 2H 2 o

0.004 NaHCO 3

80 MnCl 2 4H 2 o

0.004 Na 2 HPO 4

434 CoCl 2 ·6H 2 o

0.025 CaCl 2 2H 2 o

1 NiCl 2 ·6H 2 o

0.001 Na 2 SeO 3

0.004

[0076] Domestication of Hydroautotrophs:

[0077] The...

Embodiment 2

[0087] Reactor for excess BrO in barreled water 3 - The removal of:

[0088] Adopt implementation step 4) described method to exceed standard BrO in bottled drinking water 3 - to process. Collect commercially available partial BrO 3 - The bottled water exceeding the standard is used as the raw water of the reactor. Collecting BrO in Water Samples 3 - The concentration exceeds 0.2 to 1 times the limit value (10 μg / L) of the "Drinking Water Sanitation Standard" (GB5749-2006), that is, BrO in the influent 3 - The concentration is 12~20 μg / L. Adjust the influent flow rate of the reactor to 2.5 mL / min, and dynamically monitor the BrO in the effluent 3 - and Br - concentration. The effluent BrO 3 - and Br - The concentration ranges are listed in Table 3.

[0089] Table 3 Reactor effluent water quality

[0090] BrO 3 - Concentration / (μg / L)

Embodiment 3

[0092] Reactor to BrO in tap water 3 - The removal of:

[0093] In order to better examine the reaction of the reactor to different concentrations of BrO 3 - The removal performance to dosing BrO 3 - Tap water was used as the feed water for the reactor. Reactor feed water BrO 3 - The settings are 0.1, 0.5 and 1.0 mg / L. At the same time, tap water also contains NO 3 - -N and SO 4 2- , by adding nitrate and sulfate to make the influent NO 3 - -N concentration is 10 mg / L, SO 4 2- The concentration is 50 mg / L.

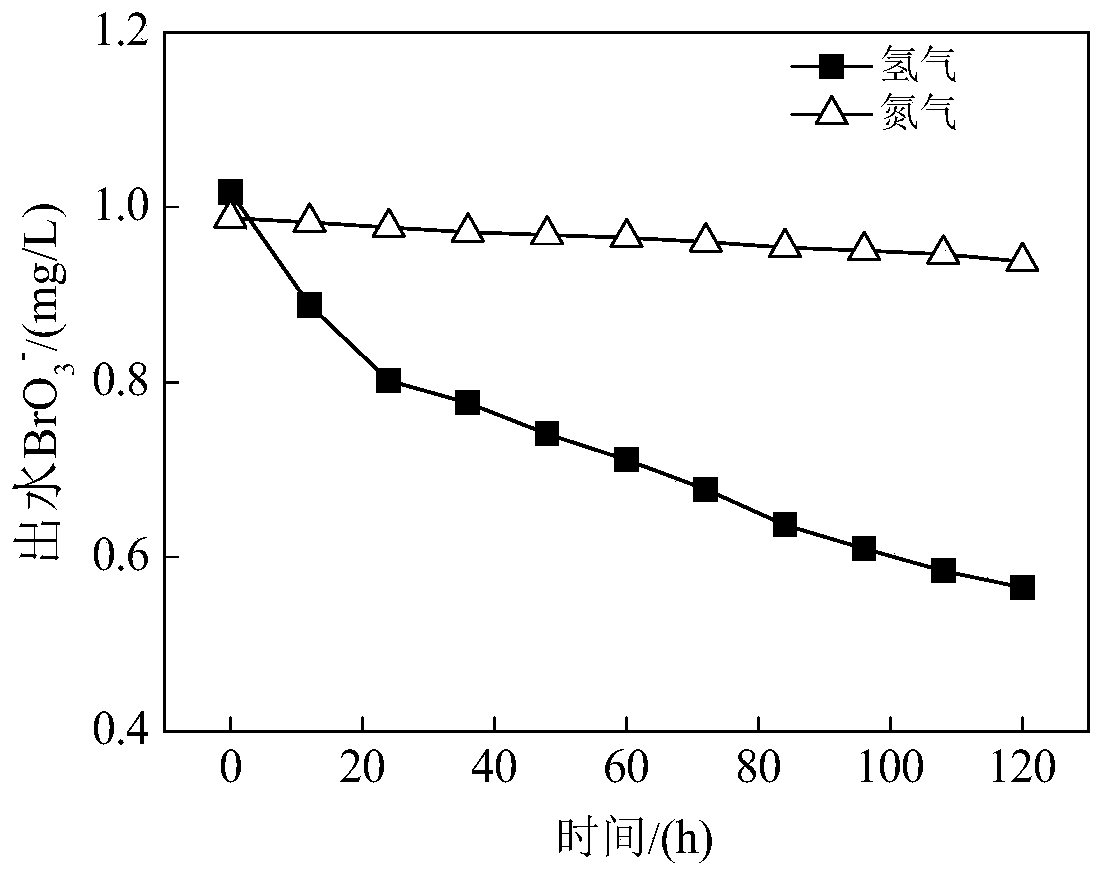

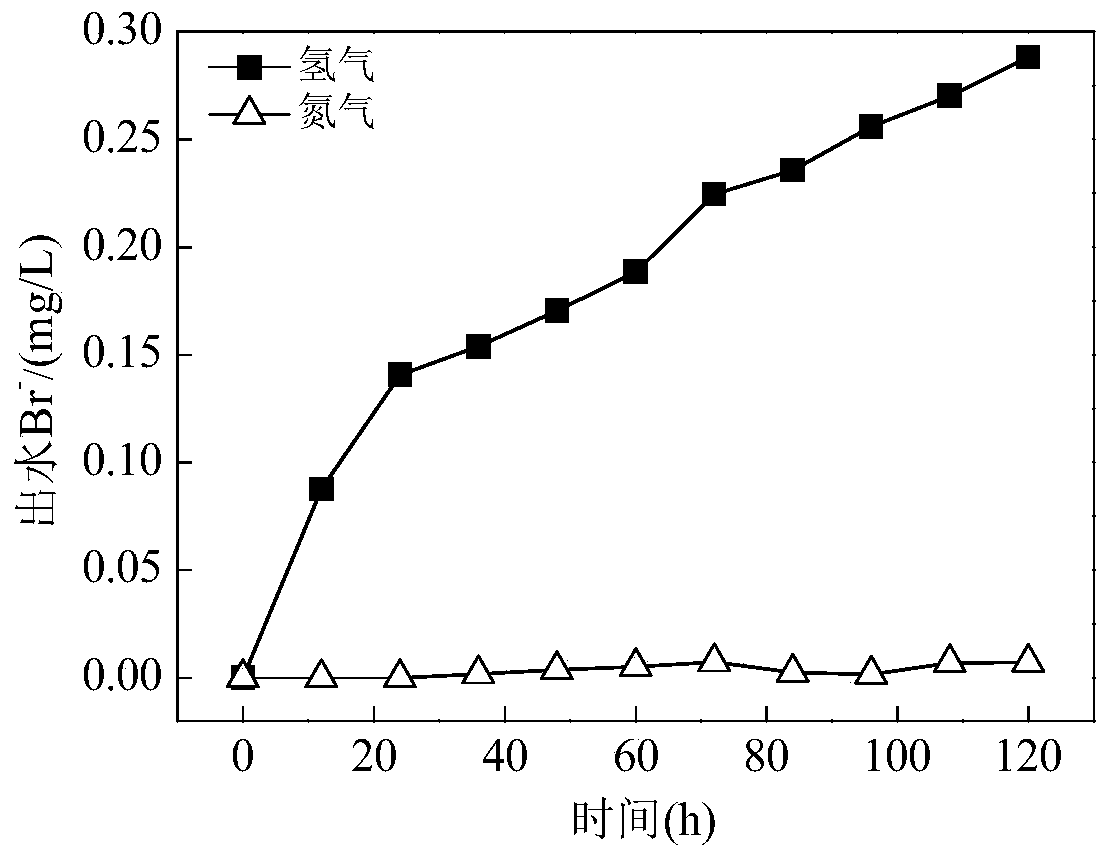

[0094] Use the method described in step 4) to investigate the treatment performance of the reactor. Reactor effluent water quality as Figure 4 shown. In the first stage, adding BrO 3 - Concentration is 0.1 mg / L, influent NO 3 - -N and SO 4 2- The concentrations are 10 mg / L and 50 mg / L respectively, and the hydrogen partial pressure is 0.04 MPa. Due to water ingress NO 3 - -N concentration is low, so denitrification effect is very good, effluent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com