Method for realizing combined treatment of sludge through high-current electrolysis, high-voltage electrodialysis and high-air-pressure pressing filtration

A technology of combined treatment and high-voltage electricity, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of high investment and operation costs, complex equipment, and difficulty in popularization and application, and achieve The effect of reducing the dry weight of sludge, low energy consumption and high economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

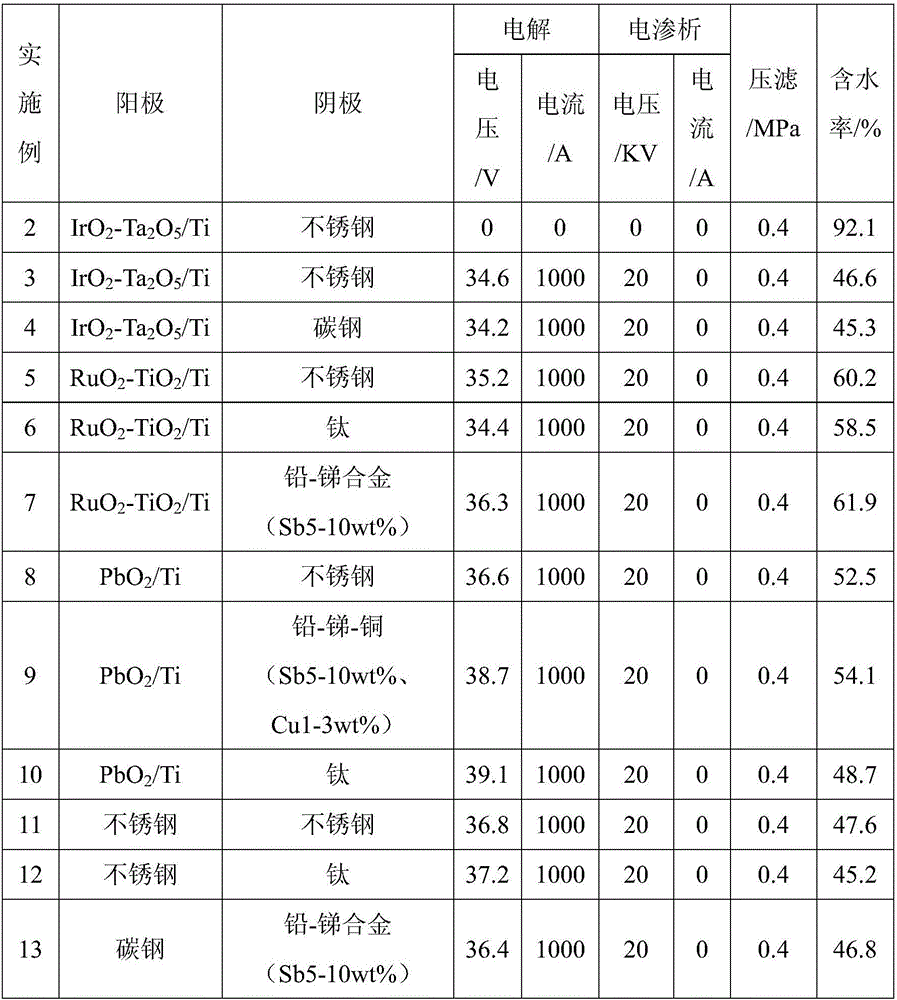

Embodiment 2--13

[0030] According to the method of the above-mentioned embodiment, in the electrolysis-electrodialysis-air pressure filtration joint treatment sludge device, the sludge comes from the urban sewage treatment plant, and the anode electrode material is respectively adopted as RuO 2 -TiO 2 / Ti, IrO2 -Ta 2 o 5 / Ti, PbO 2 / Ti, stainless steel, carbon steel; cathode materials are respectively stainless steel, carbon steel, titanium, lead-antimony (Sb5-10wt%) alloy, lead-antimony-copper (Sb5-10wt%, Cu1-3wt%) alloy. The treatment process is to pump until the filter frame is filled with sludge, electrolyze with a constant current of 1000A for 5 minutes, press filter the air at 2MPa, empty the filtrate of the screen plate, and process the mud cake with a high voltage of 20KV (frequency 50Hz) for 5 minutes with a current of 0A , the above operations were carried out at room temperature. The water content of the obtained mud cake is shown in Table 1, and the voltage is the initial volta...

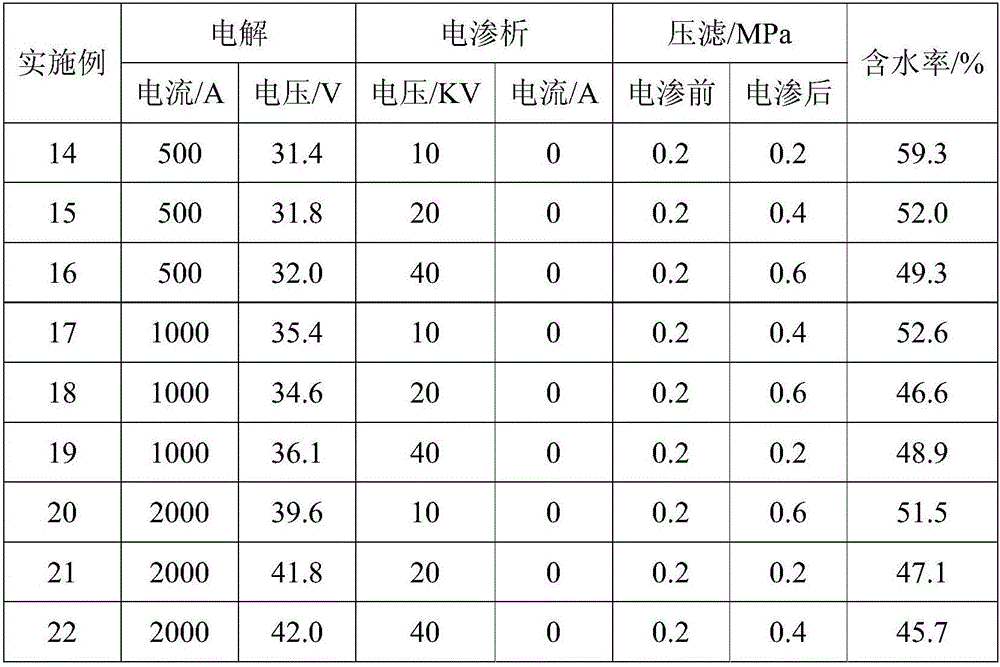

Embodiment 14-22

[0034] According to the method of embodiment 1, the city sewage plant sludge is imported by the pump. Anode is IrO 2 -Ta 2 o 5 / Ti, the cathode is made of stainless steel, different currents, pulse voltages and air pressure filter to treat sludge. The water content of the obtained mud cake is shown in Table 2.

[0035] Table 2 Results of combined treatment of sludge by electrolysis-electrodialysis-pressure filtration in different electrolysis processes

[0036]

Embodiment 23-26

[0038] According to the method of embodiment 1, the sludge from different sources is input by the pump. Anode is IrO 2 -Ta 2 o 5 / Ti, the cathode is stainless steel, electrolyzed with a current of 1000A for 5 minutes. Turn on the air compressor, compress the mud cake with air to 0.2MPa, most of the water in the mud cake will be released, turn on the high-voltage pulse stabilized voltage and current power supply, and pulse the mud cake with 20KV high voltage (frequency 50Hz) for 5 minutes, and the current is 0A . The water content of the obtained mud cake is shown in Table 3.

[0039] Table 3 Results of combined treatment of sludge from different sources of sludge by electrolysis-electroosmosis-pressure filtration

[0040] Example sludge type source of sludge Current / A Pulse voltage / KV Moisture content / % 23 municipal sludge Urban sewage plant 500 20 46.6 24 biochemical sludge Industrial Enterprises 500 20 59.1 25 river silt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com