Carbon fiber power-based carbon/carbon composite preform and shaping method and application thereof

A carbon composite material and carbon fiber powder technology, applied in ceramic molding machines, manufacturing tools, etc., can solve problems such as limited application, and achieve the effects of reducing machining amount, reducing chemical vapor deposition time and deposition cost, and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A carbon / carbon composite body based on carbon fiber powder, by weight, carbon fiber powder 30% to 80%, thermosetting resin 15% to 30%, curing agent 1.2% to 3.0%, graphite powder 0% to 50%, The flow aid is 0.1%~1.0%, the sum of each component is 100%, and the above raw materials are prepared after loading, curing and demoulding; the density of the carbon / carbon composite body is 0.7g / ㎝ 3 ~1.0g / ㎝ 3 , the strength meets the flow requirements of the process; the particle size of the carbon fiber powder is 100 mesh to 300 mesh; the graphite powder is flake graphite passing through a 800 mesh sieve; the thermosetting resin is phenolic resin; the curing agent is hexamethylene Tetramine; the flow aid is fumed silica.

[0034] A carbon / carbon composite body based on carbon fiber powder, by weight, carbon fiber powder 50% to 65%, thermosetting resin 15% to 30%, curing agent 1.2% to 3.0%, graphite powder 8% to 20%, The flow aid is 0.1%~1.0%, the sum of each component is 100%, a...

Embodiment 2

[0049] When adding materials, improve the fluidity of raw materials, the present invention in step (1), by weight, get carbon fiber powder 60%, thermosetting resin 23%, curing agent 1.8%, graphite powder 15%, flow aid 0.2%, each group The sum of the parts is 100%, and the 800㎜×800㎜×15㎜ carbon / carbon composite square plate green body is prepared after mold loading, curing and demoulding, and the density of the prepared green body is 0.72g / ㎝ 3 , the strength meets the requirements of the process flow, and the green body is prepared by chemical vapor deposition, machining, and chemical vapor deposition again to prepare 800㎜×800㎜×15㎜ carbon / carbon composite square plate products, and the product density is 1.26g / ㎝ 3 , the strength is 43MPa.

[0050] The rest are the same as embodiment 1.

Embodiment 3

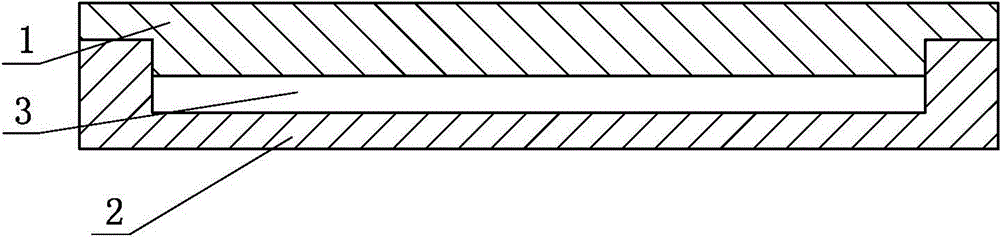

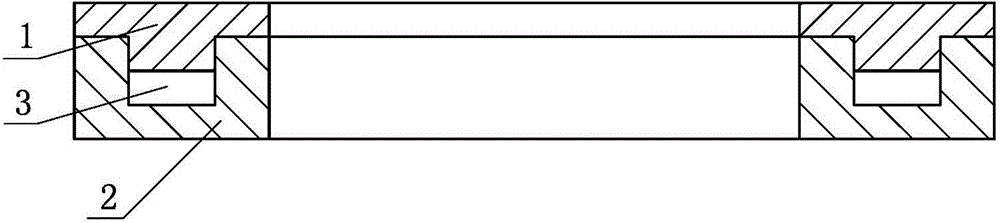

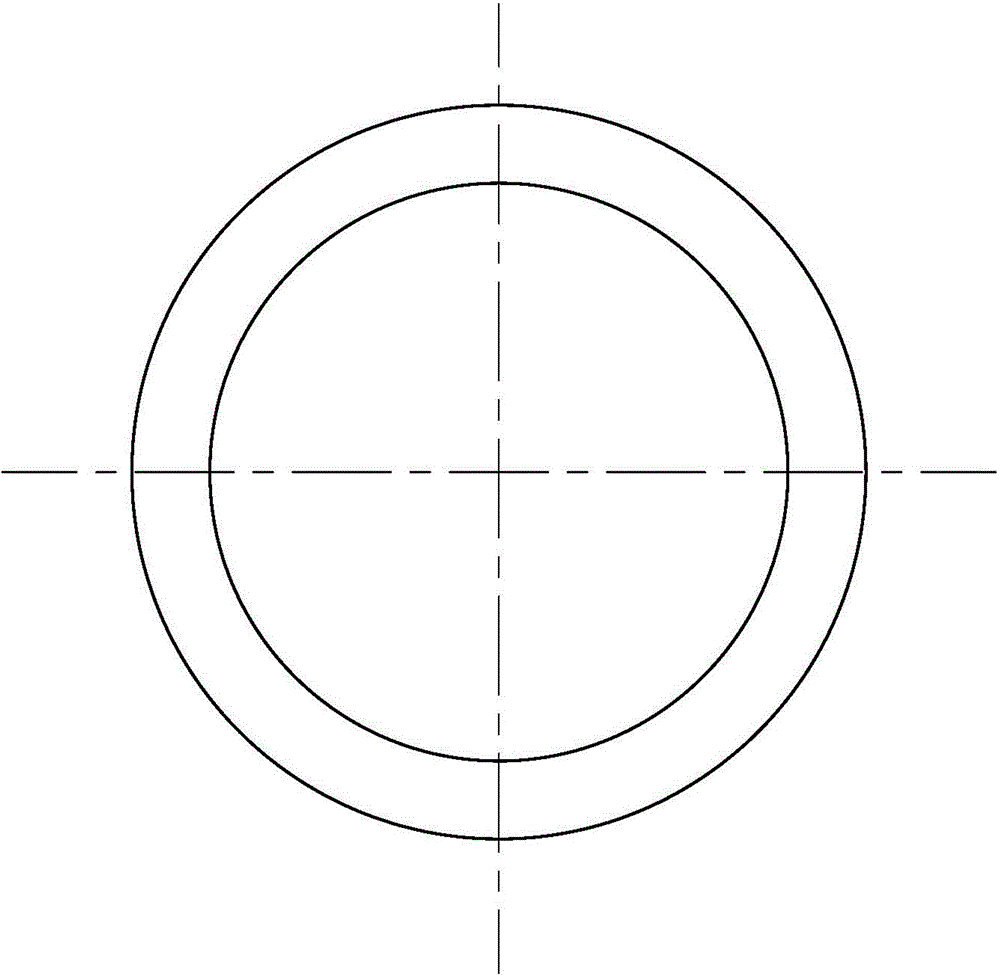

[0052] Depend on figure 2 , image 3 It can be seen that, in step (1) of the present invention, by weight, 60% of carbon fiber powder, 23% of thermosetting resin, 1.8% of curing agent, 15% of graphite powder, 0.2% of flow aid, and the sum of each component is 100%, because The green body is in the shape of an annular plate, and the opening of the female mold 2 in this embodiment is the feeding port. Pour the ball-milled raw materials into the female mold 2, vibrate, and cover the male mold 1 after meeting the size requirements; after solidification and demoulding, a ring-shaped carbon / carbon composite body is prepared, and the prepared body The density is 0.71g / ㎝ 3 , the strength meets the requirements of the process flow, and the green body is prepared by chemical vapor deposition, machining, and chemical vapor deposition again to prepare a ring-shaped carbon / carbon composite product with a product density of 1.25g / ㎝ 3 , the strength is 44MPa. Compared with the tradition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com