Method for extracting cannabidiol from cannabis

A technology of cannabidiol and marijuana, applied in the field of cannabidiol extraction, can solve the problems of psychotoxic component tetrahydrocannabinol residue and low purity of cannabidiol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

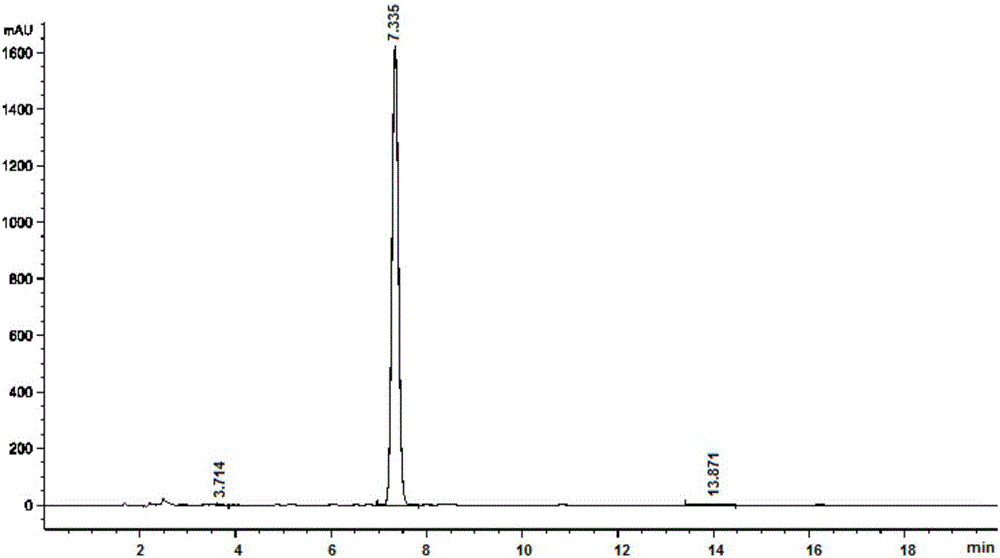

[0086] Embodiment 1: Prepare cannabidiol according to the following method

[0087] The embodiment part provides that the method of the present invention is used to prepare cannabidiol under different technical parameters. 10 kg, no further description below.

[0088] 1) crush the flowers and leaves of industrial hemp, pass through an 80-mesh sieve, and dry at a temperature of 60° C. for 3 hours to obtain medicinal material powder, whose moisture content is measured to be 4%;

[0089] 2) The above medicinal material powder was reflux extracted 3 times with twice the amount of 30% (V / V) ethanol, each time for 0.5h, to obtain an extract;

[0090] 3) The relative density measured when the above extract was concentrated to 50°C was 1.05 to obtain the extract;

[0091] 4) Use 1 times the amount of purified water for the above extract, and sink it in water at a temperature of 20°C for 1 hour to remove impurities and obtain a water sinking liquid;

[0092] 5) Centrifuge the above-...

Embodiment 2

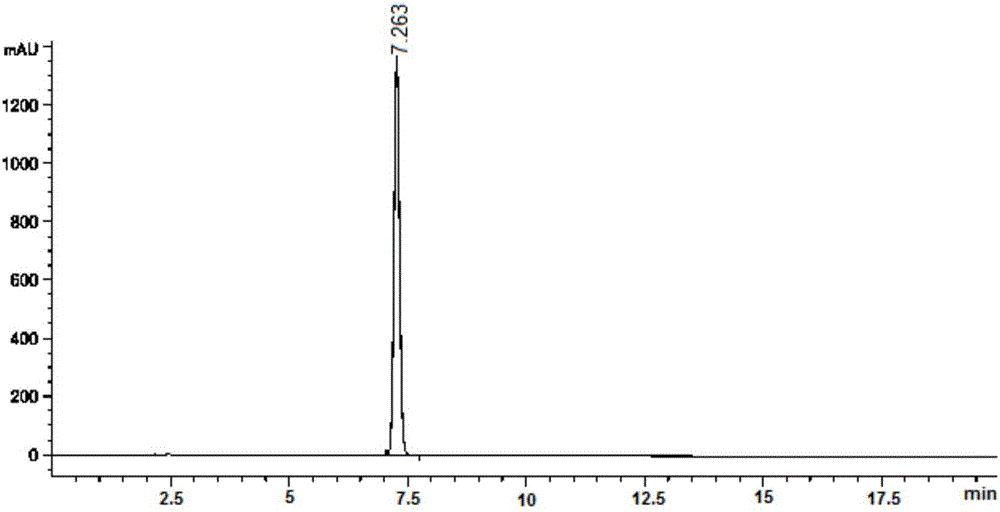

[0098] Embodiment 2: prepare cannabidiol according to the following method

[0099] 1) Pulverize the flowers and leaves of industrial hemp and pass through a 10-mesh sieve to obtain medicinal material powder. Dry at a temperature of 200°C for 0.5h to obtain medicinal material powder, and its moisture content is measured to be 2.7%;

[0100] 2) Ultrasonic extraction of the above-mentioned medicinal material powder with twice the amount of 100% (V / V) ethanol for 1 hour each time to obtain an extract;

[0101] 3) The relative density measured when the above extract was concentrated to 50°C was 1.35 to obtain an extract;

[0102] 4) Submerge the above-mentioned extract with 10 times the amount of purified water at a temperature of 0°C for 48 hours to remove impurities and obtain a water-sinking solution;

[0103] 5) Centrifuge the above-mentioned water sedimentation liquid at a speed of 10,000 rpm, add 10% (V / V) ethanol to the precipitate obtained by centrifugation to dissolve, ...

Embodiment 3

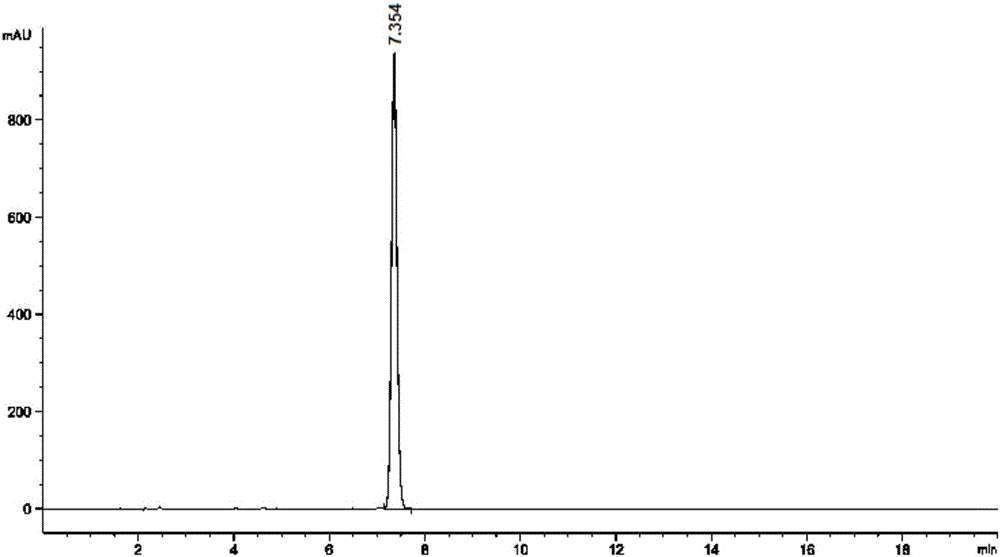

[0109] Embodiment 3: Prepare cannabidiol according to the following method

[0110] 1) The flowers and leaves of industrial hemp were crushed, passed through a 40-mesh sieve, and dried at a temperature of 130° C. for 1.7 hours to obtain medicinal material powder, the water content of which was measured to be 3.1%.

[0111] 2) Soak and extract the above medicinal material powder with 5 times the amount of 60% (V / V) ethanol for 2 times, each time for 2.5 hours, to obtain an extract;

[0112] 3) The relative density measured when the above extract was concentrated to 50°C was 1.2 to obtain the extract;

[0113] 4) Submerge the above-mentioned extract with 5 times the amount of purified water at a temperature of 10°C for 24 hours to remove impurities and obtain a water-sinking solution;

[0114] 5) Centrifuge the above-mentioned water sedimentation liquid at a speed of 7500 rpm, add 60% (V / V) ethanol to the precipitate obtained by centrifugation to dissolve, and obtain an alcohol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com