A kind of method for preparing o-methoxyphenol from lignin

A technology of o-methoxyphenol and lignin, applied in ether preparation, organic chemistry, etc., can solve the problems of poor selectivity of lignin degradation and liquefaction, difficulty in practical utilization, and complex lignin structure, so as to avoid repolymerization and side effects Reaction, low cost, and the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

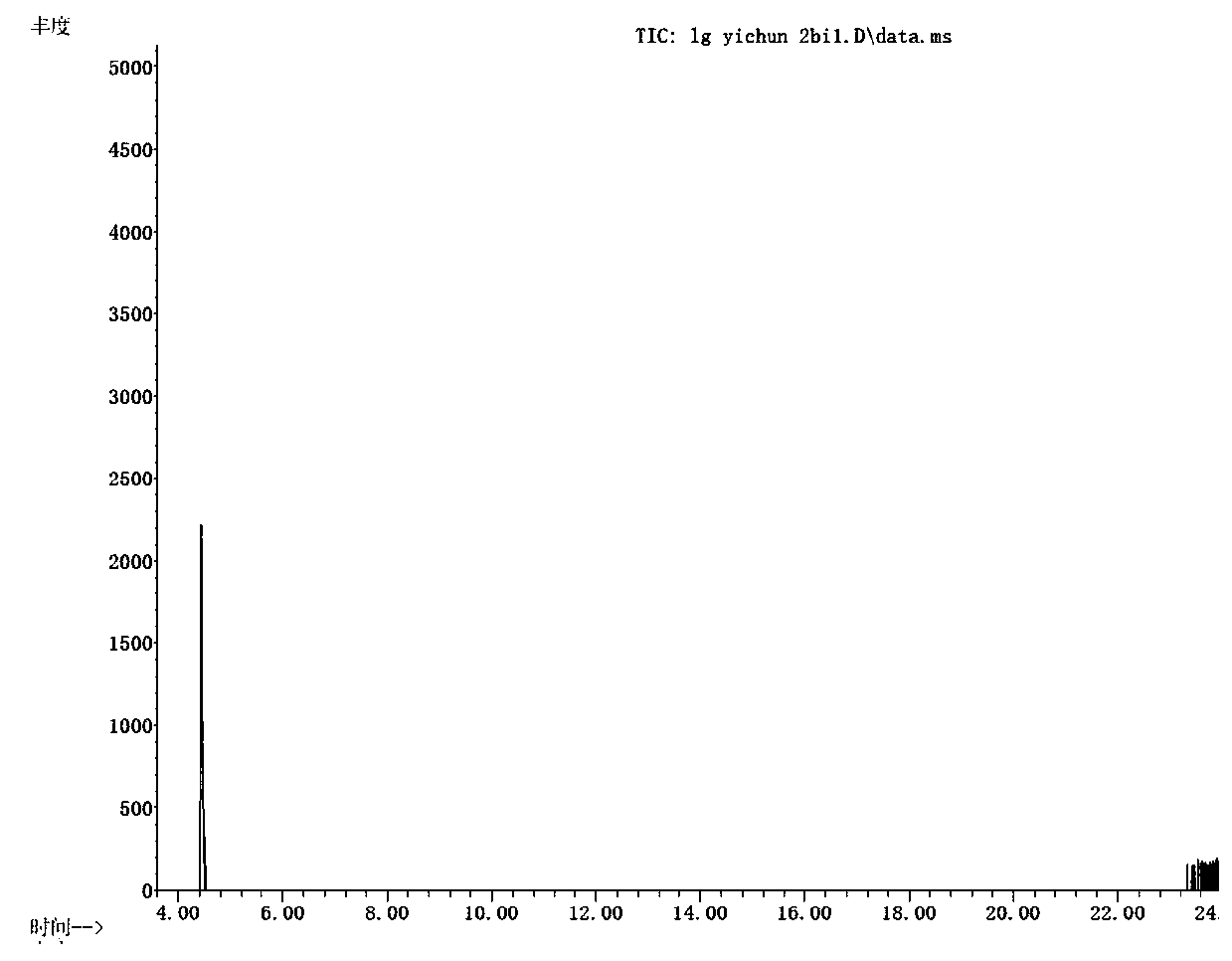

Image

Examples

Embodiment 1

[0022] Take lignin, and at room temperature, presoak and activate it with ethanol and water equal in quality to lignin, respectively, and the presoaking time is 30 minutes.

[0023] Put the preactivated lignin in a high-pressure reactor, use ethanol and water as the medium, the volume ratio of ethanol and water is 1:1, and then add the solid acid MCM-41 acidified by sulfuric acid as a catalyst, at 240 ° C After reacting for 0.5 hours, cool to room temperature, filter the reaction solution, extract the filtrate with ethyl acetate, wash the filter residue with a small amount of ethyl acetate, combine the extract and washing solution, concentrate in vacuo to obtain pure o-methoxyphenol, and recover acetic acid Ethyl ester was continued in the extraction step described above.

Embodiment 2

[0025] The lignin is taken, and it is activated by presoaking with ethanol and water respectively, and the consumption of ethanol and water are respectively 1.2 times of the lignin.

[0026] Put the preactivated lignin in a high-pressure reactor, use ethanol and water as the medium, the volume ratio of ethanol and water is 1:1, and then add the solid acid MCM-41 acidified by sulfuric acid as a catalyst, at 230 ° C After reacting for 0.5 hours, cool to room temperature, filter the reaction solution, extract the filtrate with ethyl acetate, wash the filter residue with a small amount of ethyl acetate, combine the extract and washing solution, concentrate in vacuo to obtain pure o-methoxyphenol, and recover acetic acid Ethyl ester was continued in the extraction step described above.

Embodiment 3

[0028] Take lignin, and presoak and activate it with ethanol and water respectively, and the amount of ethanol and water is respectively 3 times that of lignin.

[0029] Put the preactivated lignin in a high-pressure reactor, use ethanol and water as the medium, the volume ratio of ethanol and water is 1:1, and then add the solid acid MCM-41 acidified by sulfuric acid as a catalyst, at 200 ° C After reacting for 0.5 hours, cool to room temperature, filter the reaction solution, extract the filtrate with ethyl acetate, wash the filter residue with a small amount of ethyl acetate, combine the extract and washing solution, concentrate in vacuo to obtain pure o-methoxyphenol, and recover acetic acid Ethyl ester was continued in the extraction step described above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com