Metal ion modified melamine polyphosphate and preparation method and application thereof

A technology for modifying melamine polyphosphate and metal ions, which is applied in non-metallic elements, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of low purity of polycondensation products, low thermal stability, long polycondensation time, etc., and achieve The reaction process is stable and controllable, the high temperature stability is good, and the flame retardant effect is excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

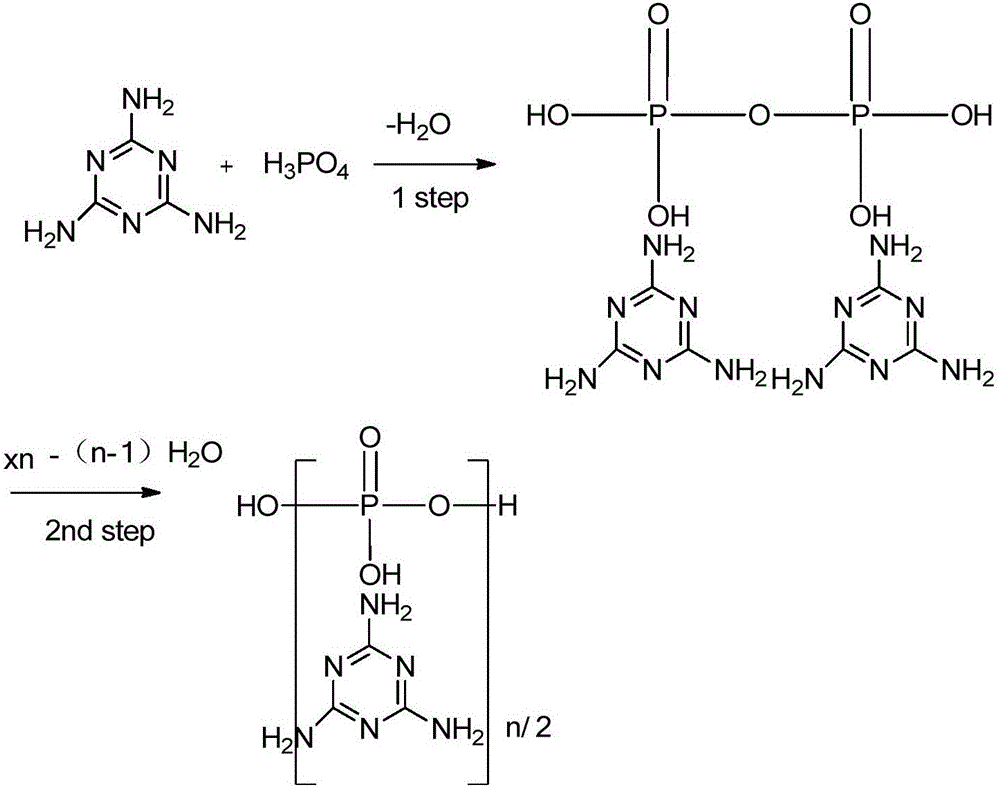

Method used

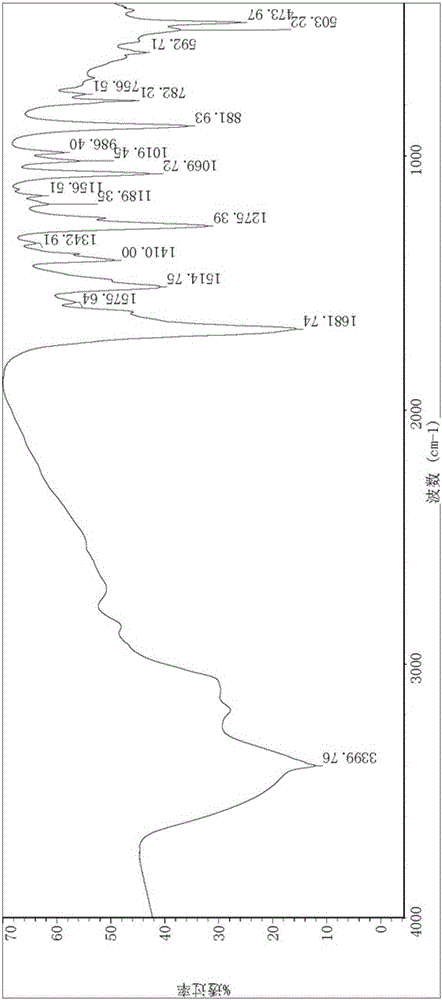

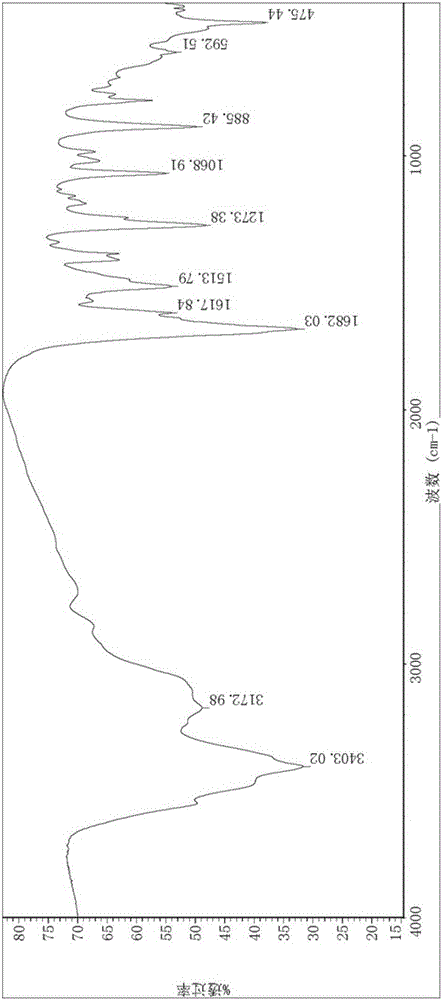

Image

Examples

Embodiment 1

[0041] (1) According to the molar ratio of melamine to phosphorus = 0.95:1, slowly add polyphosphoric acid with a degree of polymerization n of 1.2 into melamine under stirring, heat up to 80°C and react for 10 hours to obtain white powder melamine Polyphosphate prepolymer;

[0042] (2) According to the molar ratio of the metal compound and melamine as 1:10, add the metal compound to the melamine polyphosphate prepolymer, wherein the metal oxide is aluminum hydroxide, stir evenly and heat up to 270°C, and react for 5 hours. Metal ion modified melamine polyphosphate was obtained.

Embodiment 2

[0044] (1) According to the molar ratio of melamine to phosphorus = 1.15:1, slowly add polyphosphoric acid with a degree of polymerization n of 10 into melamine under stirring, heat up to 300°C and react for 1 hour to obtain white powder melamine Polyphosphate prepolymer;

[0045] (2) According to the molar ratio of the metal compound to melamine is 1:20, add the metal compound to the melamine polyphosphate prepolymer, wherein the metal oxide is magnesium hydroxide, stir evenly and heat up to 350°C, and react for 0.5h That is, the metal ion modified melamine polyphosphate is obtained.

Embodiment 3

[0047] (1) According to the molar ratio of melamine to phosphorus = 1.12:1, slowly add polyphosphoric acid with a degree of polymerization n of 8 into melamine under stirring, heat up to 150°C and react for 6 hours to obtain melamine in the form of white powder Polyphosphate prepolymer;

[0048](2) According to the molar ratio of the metal compound to melamine is 1:12, add the metal compound to the melamine polyphosphate prepolymer, wherein the metal oxide is zinc hydroxide, stir evenly and heat up to 300°C, and react for 3 hours. Metal ion modified melamine polyphosphate was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com