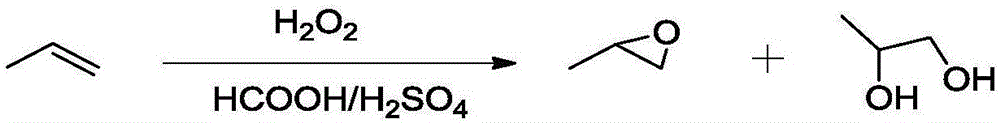

Method for preparing epoxy propane by using micro reaction device

A micro-reaction device, propylene oxide technology, applied in the direction of oxidation reaction preparation, chemical instruments and methods, chemical/physical/physicochemical reactors, etc., can solve the problems of low production value and difficult separation, and achieve short reaction time, The effect of fast response and high transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

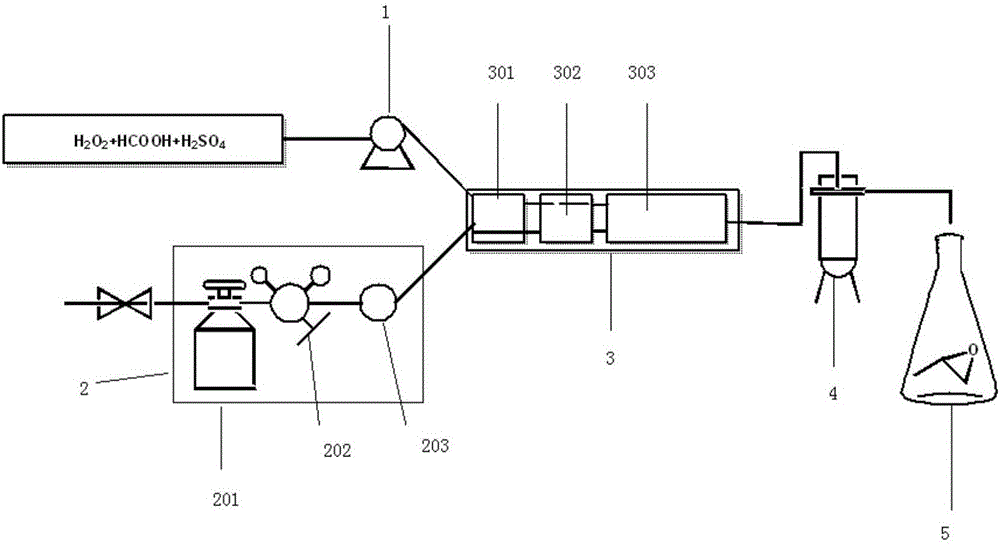

Method used

Image

Examples

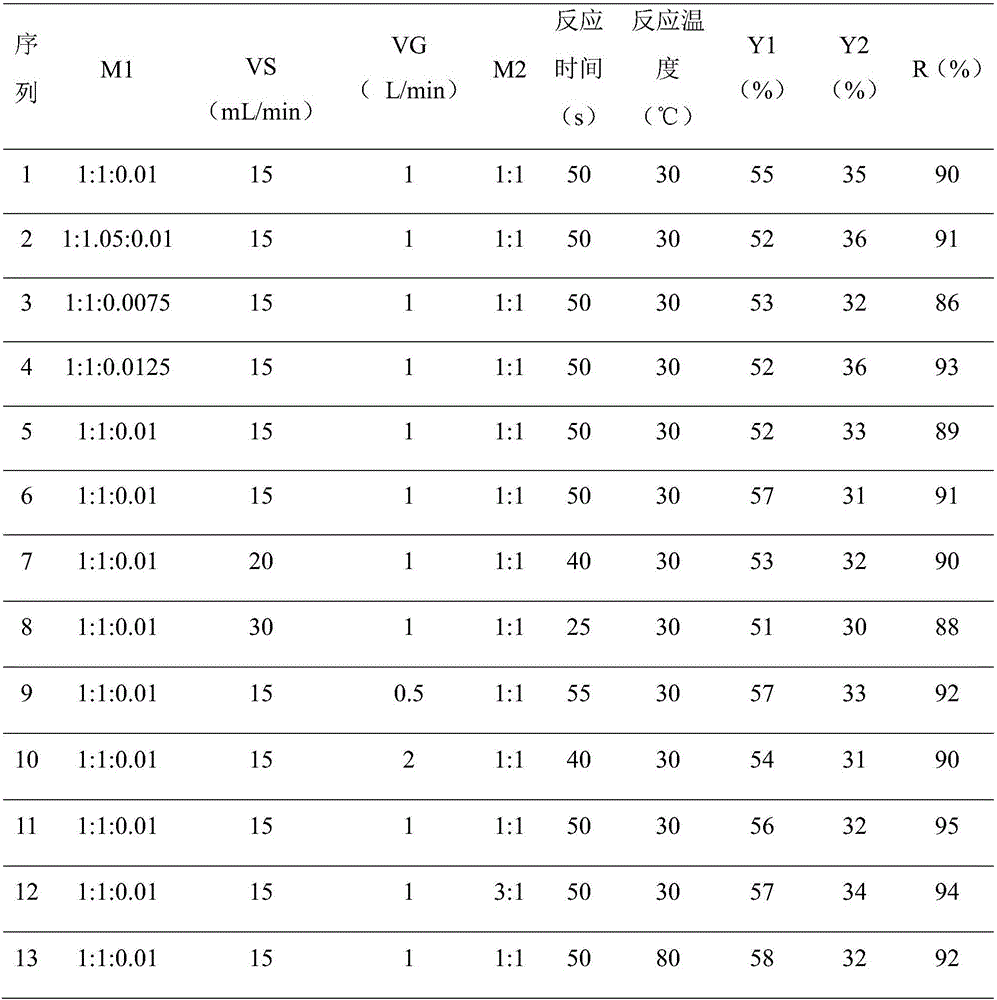

Embodiment 1

[0026] Weigh 200 g of 35% hydrogen peroxide (2.06 mol), add 140.5 g (2.06 mol) of formic acid, add 2.06 g (0.0206 mol) of sulfuric acid, and stir it into a uniform state with a stirrer. Feed nitrogen back pressure to the Corning reactor to 10bar, switch to propylene gas, and pump hydrogen peroxide material into the reactor at the same time. The liquid phase velocity is 15mL / min, the gas flow rate is 1.0L / min, the molar ratio of propylene to hydrogen peroxide is about 1:1, the reaction time is about 50s, and the reaction temperature is 30°C. The yield of propylene oxide and propylene glycol was 35% and the yield of hydrogen peroxide was 90% through indirect iodometric titration as detected by gas chromatography in the reaction solution.

Embodiment 2

[0028] Weigh 200 g of 35% hydrogen peroxide (2.06 mol), add 147.5 g (2.16 mol) of formic acid, add 2.06 g (0.0206 mol) of sulfuric acid, and stir it into a uniform state with a stirrer. Feed nitrogen back pressure to the Corning reactor to 10bar, switch to propylene gas, and pump hydrogen peroxide material into the reactor at the same time. The liquid phase velocity is 15mL / min, the gas flow rate is 1.0 / min, the molar ratio of propylene to hydrogen peroxide is about 1:1, the reaction time is about 50s, and the reaction temperature is 30°C. The yield of propylene oxide and propylene glycol was 36% and the yield of hydrogen peroxide was 91% through indirect iodometric titration as detected by gas chromatography in the reaction liquid.

Embodiment 3

[0030] Weigh 200 g of 35% hydrogen peroxide (2.06 mol), add 140.5 g (2.06 mol) of formic acid, add 1.55 g (0.0155 mol) of sulfuric acid, and stir it into a uniform state with a stirrer. Feed nitrogen back pressure to the Corning reactor to 10bar, switch to propylene gas, and pump hydrogen peroxide material into the reactor at the same time. The liquid phase velocity is 15mL / min, the gas flow rate is 1.0L / min, the molar ratio of propylene to hydrogen peroxide is about 1:1, the reaction time is about 50s, and the reaction temperature is 30°C. The yield of propylene oxide and propylene glycol was 32% as detected by gas chromatography in the reaction solution, and the conversion rate of hydrogen peroxide was 86% by indirect iodometric titration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com