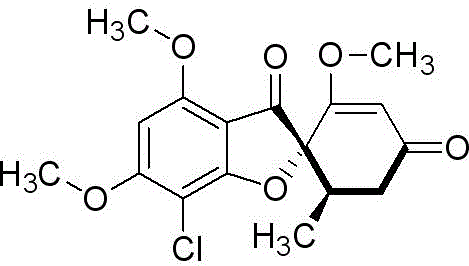

Preparation method of griseofulvin microcrystals

A technology of griseofulvin and microcrystals, which is applied in the field of preparation of griseofulvin microcrystals, can solve the problems of large particle size of griseofulvin microcrystals, achieve low production cost, simple production process, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Put 10 kg of griseofulvin raw material drug into 100 liters of acetone and heat to reflux at 45°C to dissolve. After completely dissolving, pass cooling water down to room temperature for later use. Mix 0.5 kg of sodium lauryl sulfate with 1 kg of hydroxypropyl Methylcellulose was dissolved at room temperature with 1000 liters of water, and the two solutions were mixed with a jet mixer, separated by a centrifuge and washed with 100 liters of purified water, dried under reduced pressure to obtain 9.82 kg of griseofulvin microcrystals, with an average particle size of 800 ±60nm.

Embodiment 2

[0026] Put 10 kilograms of griseofulvin bulk drug into 80 liters of dimethylformamide and heat to reflux at 100°C to dissolve. After complete dissolution, pass cooling water down to 5°C for later use. Mix 1 kilogram of tetrabutylammonium bromide with Dissolve 1 kg of methylcellulose with 1000 liters of water and cool down to 5°C, add griseofulvin dimethyl polyamide solution in a stainless steel reaction kettle under rapid stirring, separate by centrifuge and wash with 100 liters of purified water, and depressurize Dried to obtain 9.76 kg of griseofulvin microcrystals with an average particle size of 900±30nm.

Embodiment 3

[0028] Put 10 kg of griseofulvin raw material drug into 100 liters of formamide, heat and reflux at 150°C to dissolve, pass cooling water to -5°C after complete dissolution, and use 0.2 kg of dodecyl trimethyl bromide Dissolve ammonium and 0.8 kg of hydroxyethyl cellulose in 1000 liters of water and lower the temperature to -5°C. Add the formamide solution of griseofulvin into the glass-lined glass under rapid stirring, separate by centrifuge and wash with 100 liters of purified water, and depressurize Dried to obtain 9.87 kg of griseofulvin microcrystals with an average particle size of 860±50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com