Quick-dissolving type agarose with high specific surface area and preparation method thereof

A high specific surface area, instant technology, applied in the field of polymer materials, can solve the problems of low equipment utilization, high sol temperature, and difficult to dissolve, and achieve the effect of shortening process time, green production, and achieving continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

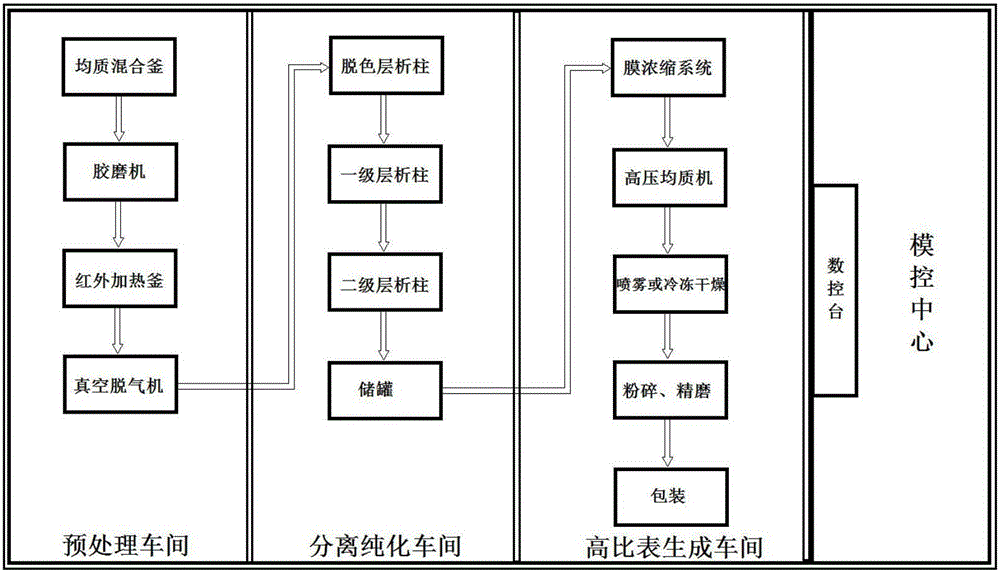

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Preparation of instant agarose with high specific surface area.

[0034] (1) Add 5000kg of water to the homogeneous mixing kettle, start the homogeneous stirring, control the frequency conversion of the rotating speed at 15Hz, then add 500kg of agar powder, and mix for 15min. Obtain ultra-micro-processed materials;

[0035] (2) Transport the above-mentioned ultramicro-processed material to an infrared heating kettle, start stirring, control the speed at 100rpm, then turn on the infrared heating controller, first set the heating temperature to 100°C, keep it for 60min, and then set the cooling temperature When the temperature is 80°C, open the cooling valve to cool down until it drops to the cooling temperature; after cooling, the material is transported to a vacuum degasser for degassing treatment to obtain a degassed material;

[0036] (3) The above-mentioned degassed material is transported to the decolorization chromatography column (the filler is silica,...

Embodiment 2

[0041] Example 2: Preparation of instant agarose with high specific surface area.

[0042] (1) Add 3000kg of water to the homogeneous mixing kettle, start the homogeneous stirring, control the frequency conversion of the rotating speed at 25Hz, then add 600kg of agar powder, and mix for 20min. After mixing, the material is transported to the rubber mill for ultrafine treatment. Obtain ultra-micro-processed materials;

[0043] (2) Transport the above-mentioned ultramicro-processed materials to an infrared heating kettle, start stirring, control the speed at 200rpm, then turn on the infrared heating controller, first set the heating temperature to 99°C, keep it for 120min, and then set the cooling temperature When the temperature is 65°C, open the cooling valve to cool down until it drops to the cooling temperature; after cooling, the material is transported to a vacuum degasser for degassing treatment to obtain a degassed material;

[0044] (3) The above-mentioned degassed mat...

Embodiment 3

[0049] Example 3: Quality detection of instant agarose with high specific surface area.

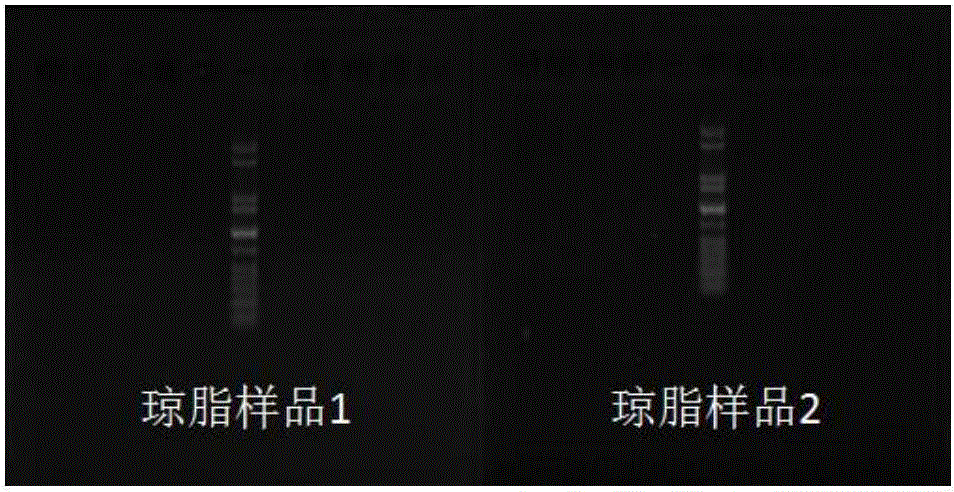

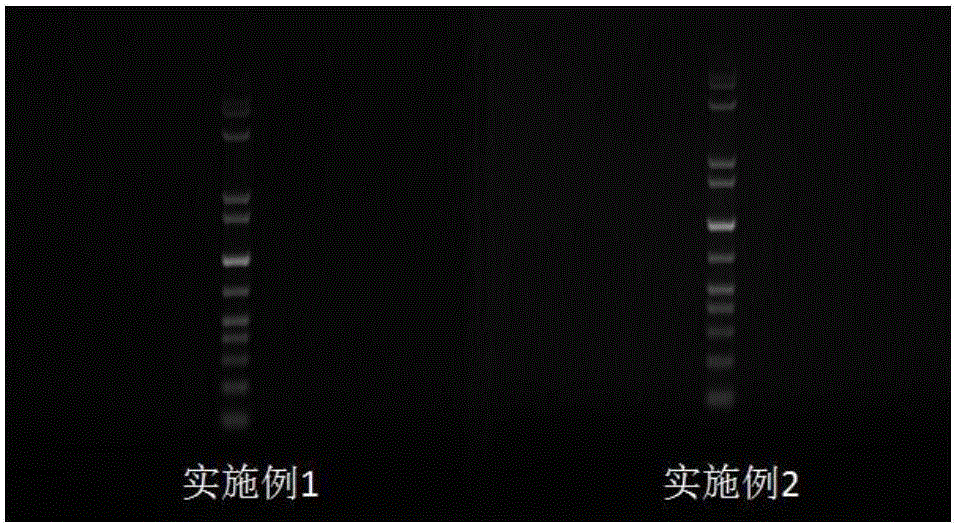

[0050] In order to investigate whether the instant agarose with high specific surface area of the present invention reaches the requirements of high specific surface area and easy dissolution, the agar raw material (Fujian Lvqi Food Colloid Co., Ltd.) and the agar prepared by the method recorded in Example 1 were used Sugar products were tested for quality, and the results are shown in Table 1 and Table 2. In addition, the agarose product prepared by the method described in Example 1 is carried out to the agar raw material and the agarose product is carried out electrophoresis test, and its result is as follows figure 2 shown.

[0051] Table 1. Agar raw material quality report

[0052]

[0053]

[0054] Table 2. Quality Report for Instant Agarose with High Surface Area

[0055]

[0056] As can be seen from above Table 1 and Table 2, the product color of the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com