A kind of modified polyvinyl alcohol copolymer and its preparation and gel polymer electrolyte

A technology of polyvinyl alcohol copolymer and gel polymer, which is applied in the direction of hybrid capacitor electrolyte, etc., can solve the problems of poor electrolyte resistance and easy flocculation, and achieve the effect of improving mechanical properties and capacitance properties, and excellent electrolyte resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

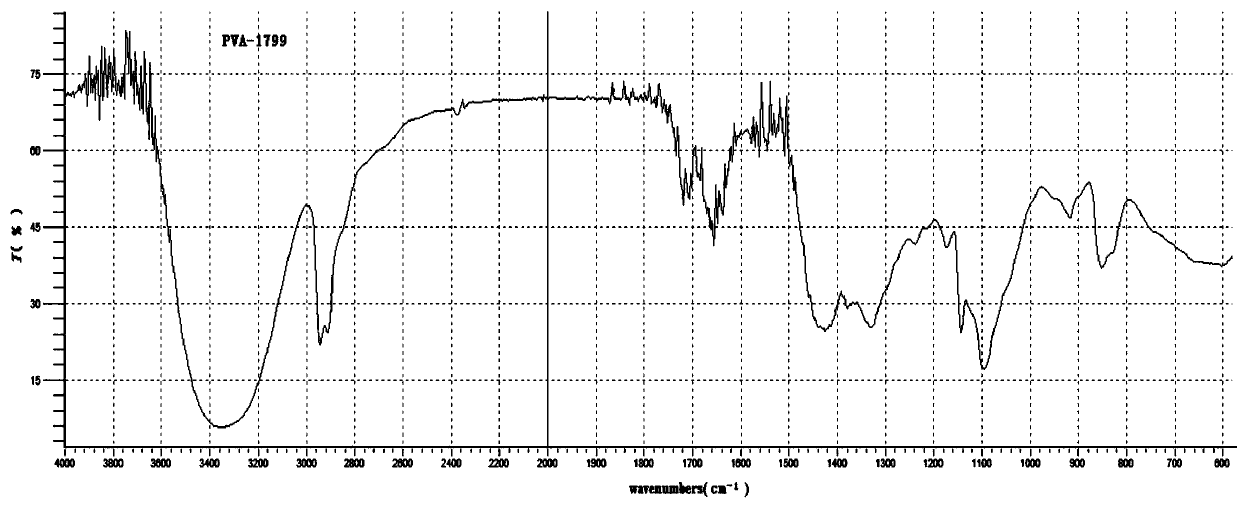

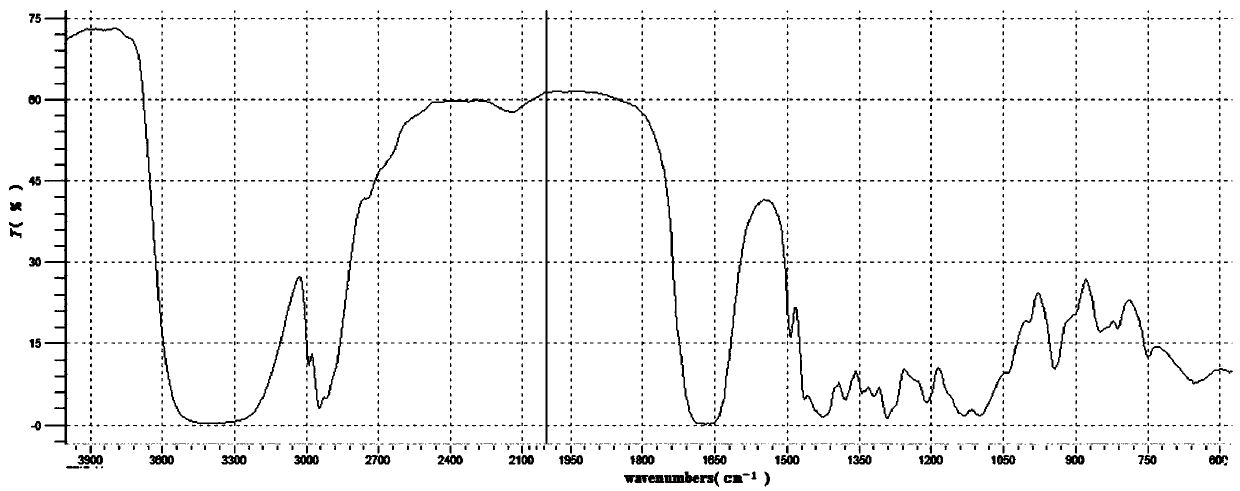

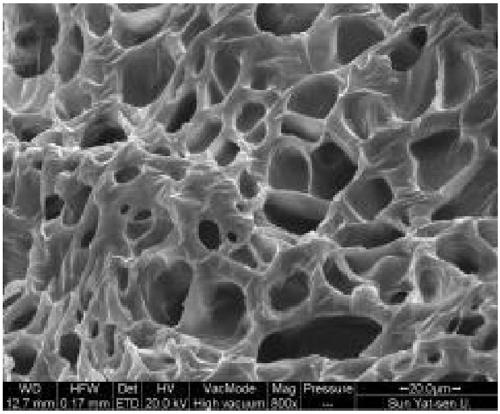

[0030] Embodiment 1, modified polyvinyl alcohol copolymer of the present invention and preparation thereof

[0031] S1. Dissolution of polyvinyl alcohol: Weigh 10g of polyvinyl alcohol solid and place it in a three-necked flask, add 50mL of water, heat it in a water bath at 60°C, stir and swell for 0.5h, and add water during the swelling process to make the total volume 60mL ; Then raise the temperature to 95°C, keep stirring at 95°C until the polyvinyl alcohol solid is completely dissolved, and cool naturally to obtain a polyvinyl alcohol solution for later use;

[0032] S2. Graft modification of polyvinyl alcohol: Weigh 8 g of the polyvinyl alcohol solution, put it into a three-necked flask, and heat it in a water bath at 40-45°C; then pass argon gas into the three-necked flask for 4 After ~6min, add 7mL of N-vinylpyrrolidone and 0.4mL of 2-hydroxyethyl methacrylate, stir evenly, then add acidic cerium ion solution; keep the water bath temperature at 40-45°C, continue argon ...

Embodiment 2

[0034] Embodiment 2, modified polyvinyl alcohol copolymer of the present invention and preparation thereof

[0035] S1. Dissolution of polyvinyl alcohol: Weigh 10g of polyvinyl alcohol solid and place it in a three-necked flask, add 50mL of water, heat it in a water bath at 60°C, stir and swell for 0.5h, and add water during the swelling process to make the total volume 60mL ; Then raise the temperature to 95°C, keep stirring at 95°C until the polyvinyl alcohol solid is completely dissolved, and cool naturally to obtain a polyvinyl alcohol solution for later use;

[0036] S2. Graft modification of polyvinyl alcohol: Weigh 12 g of the polyvinyl alcohol solution, put it into a three-necked flask, and heat it in a water bath at 40-45°C; then pass argon gas into the three-necked flask, 4 After ~6min, add 14mL of N-vinylpyrrolidone and 1mL of glycidyl methacrylate, stir well, then add acidic cerium ion solution; keep the temperature of the water bath at 40-45°C, continue to pass ar...

Embodiment 3

[0038] Embodiment 3, modified polyvinyl alcohol copolymer of the present invention and preparation thereof

[0039] S1. Dissolution of polyvinyl alcohol: Weigh 10g of polyvinyl alcohol solid and place it in a three-necked flask, add 50mL of water, heat it in a water bath at 60°C, stir and swell for 0.5h, and add water during the swelling process to make the total volume 60mL ; Then raise the temperature to 95°C, keep stirring at 95°C until the polyvinyl alcohol solid is completely dissolved, and cool naturally to obtain a polyvinyl alcohol solution for later use;

[0040] S2. Grafting modification of polyvinyl alcohol: Weigh 10 g of the polyvinyl alcohol solution, put it into a three-necked flask, and heat it in a water bath at 40-45°C; then pass argon gas into the three-necked flask, 4 After ~6min, add 12mL of N-vinylpyrrolidone and 0.7mL of 2-hydroxyethyl methacrylate, stir evenly, then add acidic cerium ion solution; keep the water bath temperature at 40-45°C, continue argo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com