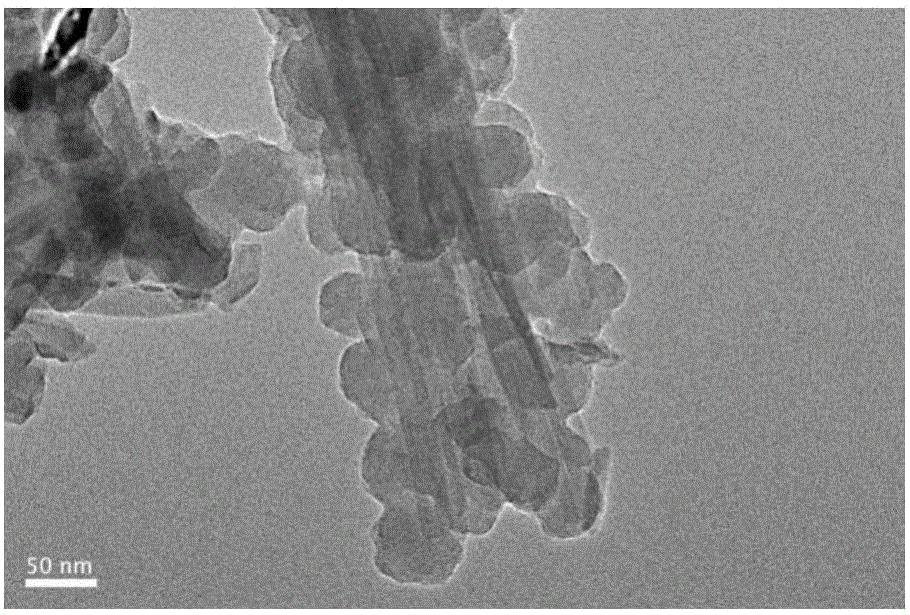

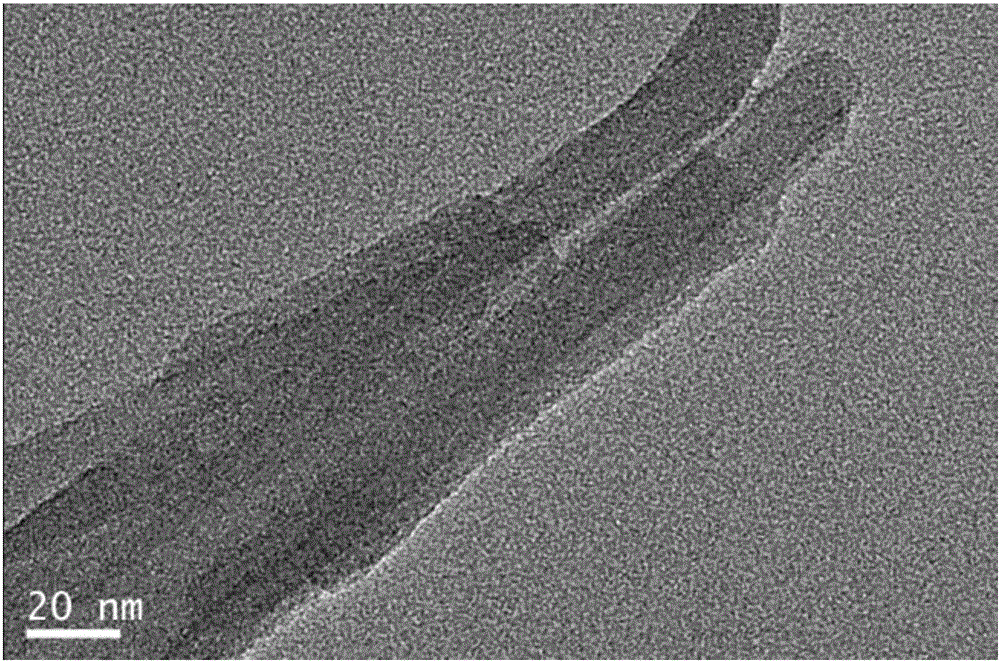

Preparation method and application of one-dimensional rod-spherical attapulgite/polyaniline conductive composite

A conductive composite material and attapulgite technology, applied in conductive coatings and other directions, can solve the problems of high cost and high price of conductive fillers, and achieve the effects of improving conductivity, promoting dispersion and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

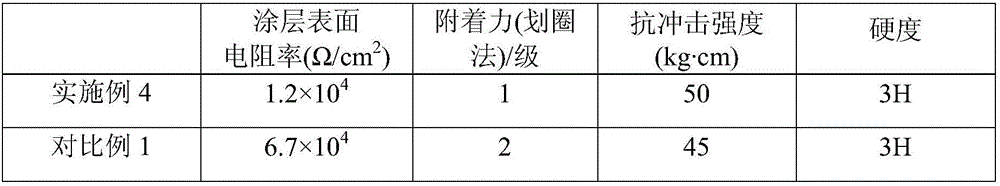

Examples

Embodiment 1

[0020] (1) 0.25 kg Fe(NO 3 ) 3 9H 2 O was dissolved in 1.0 kg of attapulgite rod crystal dispersion liquid with a concentration of 10% by mass. After immersion for 2 hours, while stirring, an ammonia solution with a molar concentration of 2 mol / liter was added dropwise until the pH value of the system could be maintained stably. In 9, filter, wash the filter cake and dry at 300°C for 4 hours in an air atmosphere, cool to room temperature and pulverize to obtain Fe 2 o 3 / Attapulgite composite material;

[0021] (2) Fe obtained in step (1) 2 o 3 / Add the attapulgite composite material to 2.0 kg of deionized water, ultrasonically disperse it for 60 minutes, add 0.145 kg of aniline monomer, stir for 3 hours, and slowly pour it into the above mixture while stirring at a temperature of 5°C. Add dropwise 4.68 liters of hydrochloric acid solution with a molar concentration of 2 mol / liter, continue to stir and react for 8 hours after the dropwise addition, filter, wash the fil...

Embodiment 2

[0023] (1) 0.075 kg Fe(NO 3 ) 3 9H 2 O was dissolved in 1.0 kg mass percent concentration of 10% attapulgite rod crystal dispersion, after 6 hours of immersion, while stirring, dropwise added ammonia solution with a molar concentration of 1 mol / liter until the system pH value can be maintained stably In 8, filter, wash the filter cake and dry at 200°C for 1 hour in an air atmosphere, cool to room temperature and pulverize to obtain Fe 2 o 3 / Attapulgite composite material;

[0024] (2) Fe obtained in step (1) 2 o 3 / Add the attapulgite composite material to 2.0 kg of deionized water, ultrasonically disperse it for 30 minutes, add 0.027 kg of aniline monomer, stir for 1 hour, and slowly pour it into the above mixture while stirring at a temperature of 0°C. Add dropwise 2.5 liters of hydrochloric acid solution with a molar concentration of 4 mol / liter, continue to stir and react for 4 hours after the dropwise addition, filter, wash the filter cake until the pH value of t...

Embodiment 3

[0026] (1) 0.165 kg Fe(NO 3 ) 3 9H 2 O was dissolved in 1.0 kg mass percent concentration of 10% attapulgite rod crystal dispersion, after 4 hours of immersion, while stirring, dropwise added ammonia solution with a molar concentration of 1.5 mol / liter until the pH value of the system can be maintained stably In 8.5, filter, wash the filter cake and dry at 250°C for 2.5 hours in an air atmosphere, cool to room temperature and pulverize to obtain Fe 2 o 3 / Attapulgite composite material;

[0027] (2) Fe obtained in step (1) 2 o 3 / Add the attapulgite composite material to 2.0 kg of deionized water, ultrasonically disperse for 45 minutes, add 0.105 kg of aniline monomer, stir for 2 hours, and slowly pour it into the above mixture while stirring at a temperature of 2.5°C Add dropwise 3.12 liters of hydrochloric acid solution with a molar concentration of 3 mol / liter, continue to stir and react for 6 hours after the dropwise addition, filter, wash the filter cake until the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com