Method for improving stability of copper ion ink and conductivity of copper film

A copper ion and stability technology, which is applied in the field of improving the stability of copper ion ink and the conductivity of copper film, can solve the problems that the stability of copper ion ink and the conductivity of copper film cannot meet the use requirements at the same time, and achieve both room temperature stability , Ease of storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of ink stock solution: Add phenolic resin to absolute ethanol and stir evenly; then, according to the complexation ratio of 1:2, anhydrous copper formate from copper source, ligand 2-ethylhexylamine and 2-amino- Dissolve 2-methyl-1-propanol in the above-mentioned ethanol solution, fully stir at 35°C, and prepare ink stock solution, wherein the mass fraction of copper ions is 9.5%, the mass fraction of phenolic resin is 0.1%, and 2-ethylhexylamine accounts for The molar percentage of total ligands is 95%;

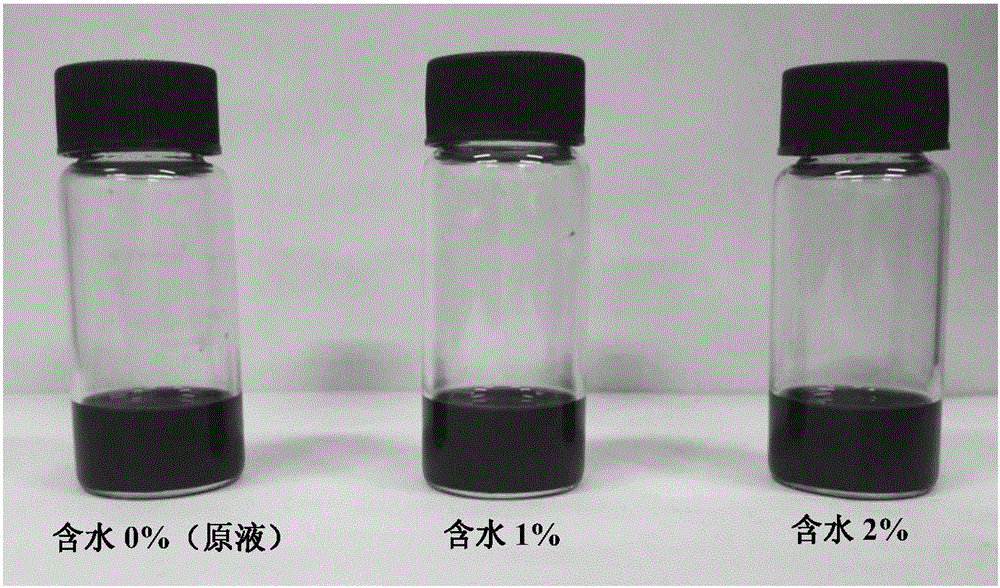

[0026] (2) Preparation of ready-to-use ink: add ultrapure water to the ink stock solution obtained in step (1) one day before printing, mix evenly, the mass fraction of ultrapure water is 1-2%, and seal the ink at room temperature after preparation;

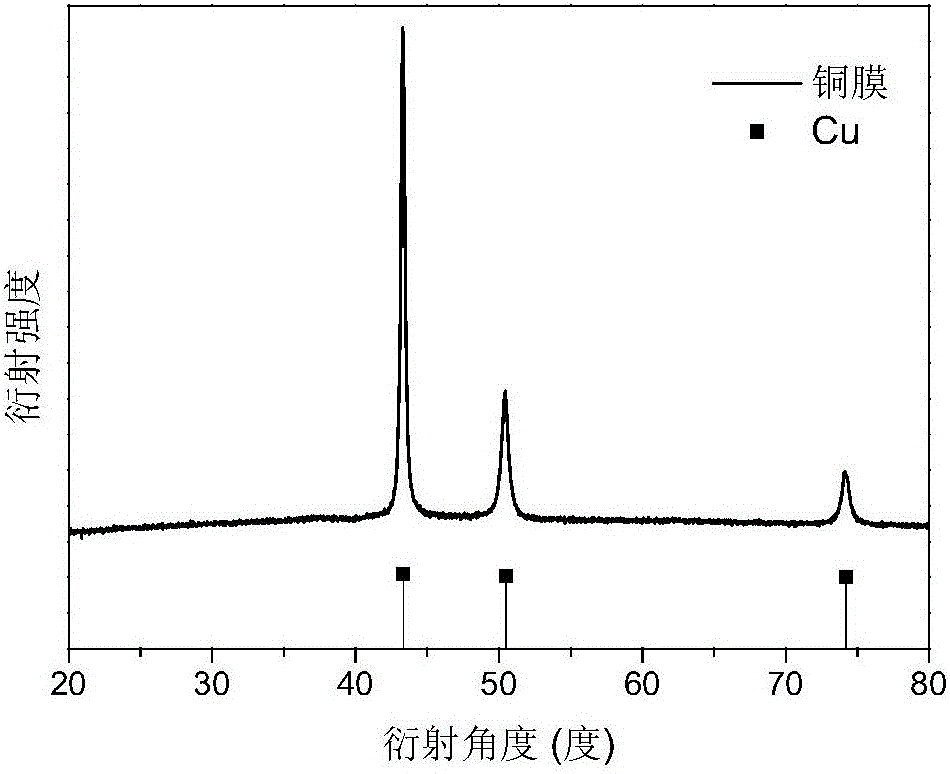

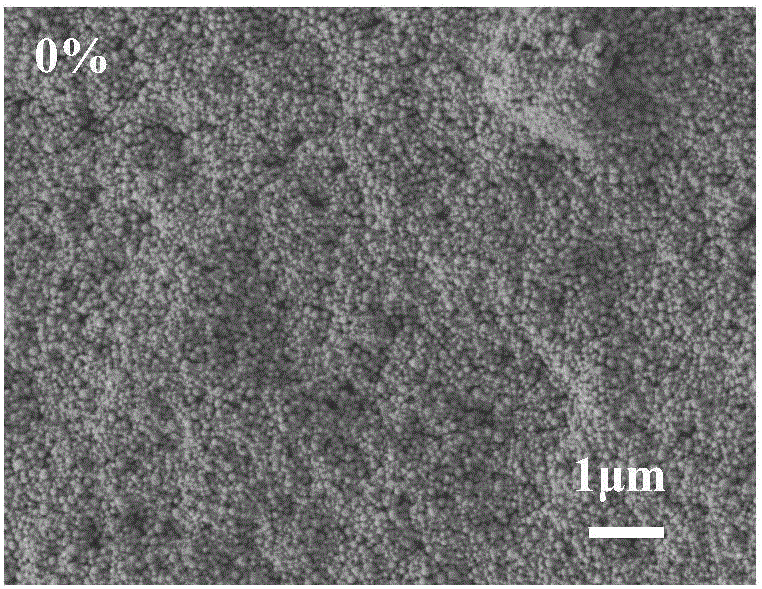

[0027] (3) Print the ink prepared in step (2) on the polyimide film, ventilate and dry it at 50°C, and then transfer it to 250°C for heating for 30min under a nitrogen atmosphere to obtain a copper film; ...

Embodiment 2

[0030] (1) Prepare stock solution: add polyamide resin to absolute ethanol, stir evenly; then according to the complexation ratio of 1:2, anhydrous copper formate of copper source, ligand n-octylamine and 2-amino-2-formazol Base-1-propanol was dissolved in the above ethanol solution, fully stirred at 35°C, and prepared into an ink stock solution, wherein the mass fraction of copper ions was 9%, the mass fraction of polyamide was 0.1%, and the molar percentage of n-octylamine to the total ligands 75%;

[0031] (2) Preparation of ready-to-use ink: add ultrapure water to the ink stock solution obtained in step (1) one day before printing, mix evenly, the mass fraction of ultrapure water is 0.5-2%, and seal the ink at room temperature after preparation;

[0032] (3) Print the ink prepared in step (2) on a glass plate, ventilate and dry at 50°C, and then transfer to a nitrogen atmosphere and heat at 200°C for 30min to obtain a copper film;

[0033] (4) The surface resistance and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com