Waterproof paint for automobile chassis and preparation method of waterproof paint

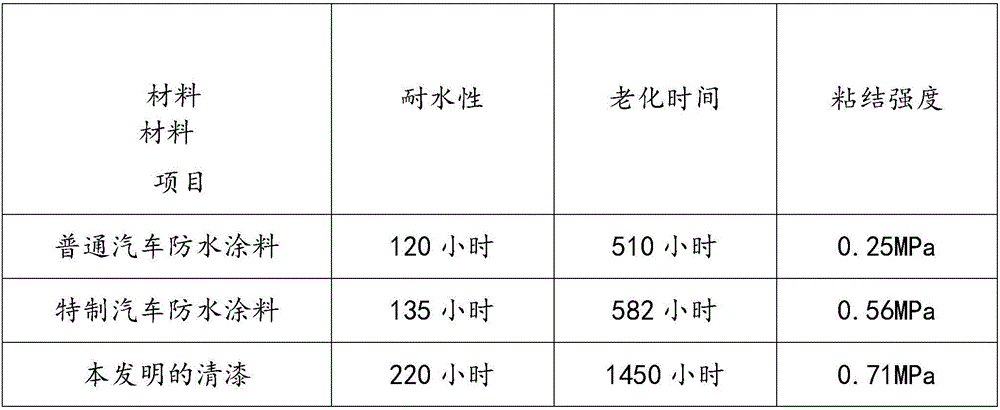

A technology for waterproof coatings and automobile chassis, applied in the direction of polyamide coatings, coatings, etc., can solve the problems of poor anti-aging effect, low bonding strength, poor water resistance, etc., and achieve good anti-aging effect and adhesion. High strength and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of waterproof paint for automobile chassis, made of the following materials in proportion by weight, including 13 parts of acrylic emulsion, 25 parts of polyvinyl acetate, 33 parts of styrene-butadiene rubber emulsion, 5 parts of dimethyl silicone oil, 6 parts of talcum powder 9 parts, 9 parts of sodium hexametaphosphate, 5 parts of polydiacetone acrylamide, 7 parts of turpentine oil, 8 parts of zinc stearate, 13 parts of triethoxysilane, 22 parts of polyisocyanate, 9 parts of tetrabutyl phosphorus chloride, 8 parts of polyamide wax, 17 parts of carboxymethyl cellulose, 9 parts of sodium polyacrylate, 7 parts of xanthan gum, 12 parts of difenoconazole, 6 parts of bentonite, 11 parts of N-phenyl-β-naphthylamine and 9 parts of p-phenylenediamine.

[0018] A kind of preparation method of the waterproof paint of automobile chassis, comprises the following steps:

[0019] 1) Mix 13 parts of acrylic emulsion, 25 parts of polyvinyl acetate, 33 parts of styrene-butadien...

Embodiment 2

[0024] A kind of waterproof coating for automobile chassis, made of the following materials in parts by weight, including 14 parts of acrylic emulsion, 27.5 parts of polyvinyl acetate, 35.5 parts of styrene-butadiene rubber emulsion, 6.5 parts of simethicone oil, 8.5 parts of talcum powder Parts, 12 parts of sodium hexametaphosphate, 7.5 parts of polydiacetone acrylamide, 8.5 parts of turpentine oil, 11 parts of zinc stearate, 15.5 parts of triethoxysilane, 23 parts of polyisocyanate, 12.5 parts of tetrabutyl phosphorus chloride, 11 parts of polyamide wax, 18.5 parts of carboxymethyl cellulose, 11 parts of sodium polyacrylate, 7.5 parts of xanthan gum, 14 parts of difenoconazole, 8 parts of bentonite, 14 parts of N-phenyl-β-naphthylamine and 11.5 parts of p-phenylenediamine.

[0025] A kind of preparation method of the waterproof paint of automobile chassis, comprises the following steps:

[0026] 1) 14 parts of acrylic emulsion, 27.5 parts of polyvinyl acetate, 35.5 parts of...

Embodiment 3

[0031] A waterproof coating for automobile chassis, made of the following materials in parts by weight, including 15 parts of acrylic emulsion, 30 parts of polyvinyl acetate, 38 parts of styrene-butadiene rubber emulsion, 8 parts of simethicone, and 11 parts of talcum powder 15 parts of sodium hexametaphosphate, 10 parts of polydiacetone acrylamide, 10 parts of turpentine oil, 14 parts of zinc stearate, 18 parts of triethoxysilane, 24 parts of polyisocyanate, 16 parts of tetrabutyl phosphorus chloride, 14 parts of polyamide wax, 20 parts of carboxymethyl cellulose, 13 parts of sodium polyacrylate, 8 parts of xanthan gum, 16 parts of difenoconazole, 10 parts of bentonite, 17 parts of N-phenyl-β-naphthylamine and 14 parts of p-phenylenediamine.

[0032] A kind of preparation method of the waterproof paint of automobile chassis, comprises the following steps:

[0033] 1) Mix 15 parts of acrylic emulsion, 30 parts of polyvinyl acetate, 38 parts of styrene-butadiene rubber emulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com