Drilling fluid-fluid loss additive prepared from landfill leachate and preparation method thereof

A technology of landfill leachate and fluid loss reducing agent, applied in chemical instruments and methods, drilling composition and other directions, can solve the problem of unstable fluid loss of drilling fluid performance, complex formation structure, and inability to obtain oil and gas resources well Mining and service issues, to achieve the effect of maintaining temperature resistance, broadening the scope of application, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A kind of preparation method of the drilling fluid fluid loss control agent that utilizes landfill leachate to prepare, it comprises the following steps:

[0023] Step S1: Add the concentrated landfill leachate to the concentrated sulfuric acid according to the mass ratio of the concentrated landfill leachate to concentrated sulfuric acid at a ratio of 5 to 10:1, and adjust the temperature of the reaction system to 140 to 180°C for constant temperature reaction 3 After ~6 hours, filter out the solid matter in the mixed solution and wash it repeatedly with distilled water. When the pH of the washed water is neutral, dry the solid matter to obtain sulfonated humic acid;

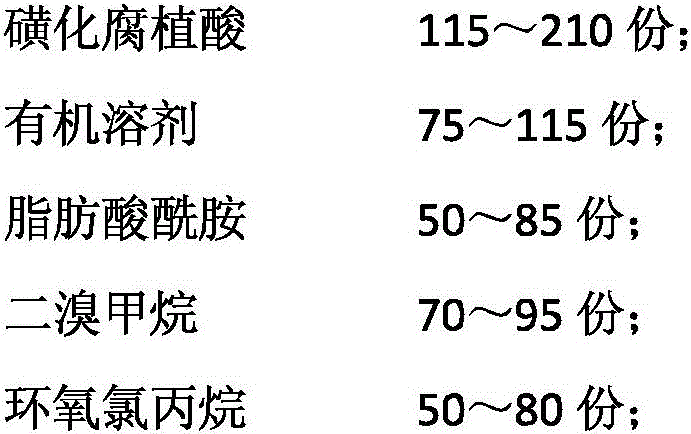

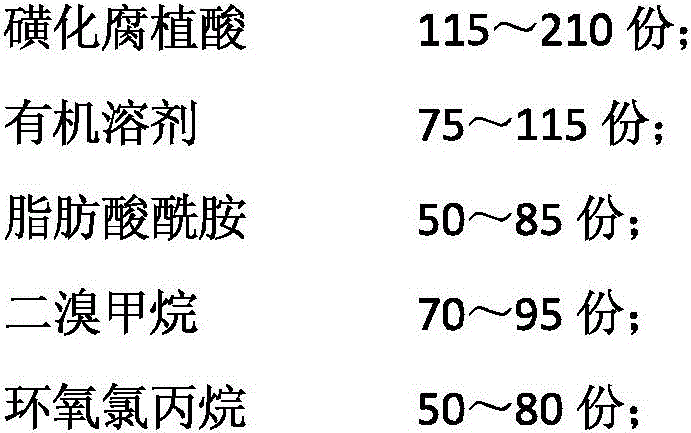

[0024] Step S2: Weigh 115 to 210 parts of the sulfonated humic acid prepared above and add it to 75 to 115 parts of organic solvent for dissolution, then add 50 to 85 parts of fatty acid amide, and under the protective atmosphere of continuous feeding of nitrogen, the Adjust the temperature of the reacti...

Embodiment 1

[0029] A kind of preparation method of the drilling fluid fluid loss control agent that utilizes landfill leachate to prepare, it comprises the following steps:

[0030] Step S1: Add 400 parts of landfill leachate concentrate with a solid content of 15% to 80 parts of concentrated sulfuric acid, adjust the temperature of the reaction system to 140°C for constant temperature reaction for 5 hours, filter out the solid matter in the mixed solution and use Repeated washing with distilled water, when the pH of the washed water is neutral, the solid matter can be dried to obtain sulfonated humic acid;

[0031] Step S2: Weigh 200 parts of the sulfonated humic acid prepared above and add it to 115 parts of liquid paraffin for dissolution, then add 50 parts of fatty acid amide, and adjust the temperature of the reaction system to 140 ℃ for 0.5h;

[0032] Step S3: Add the reaction product of step S2 together with 80 parts of dibromomethane and 75 parts of epichlorohydrin into the react...

Embodiment 2

[0034] A kind of preparation method of the drilling fluid fluid loss control agent that utilizes landfill leachate to prepare, it comprises the following steps:

[0035] Step S1: Add 450 parts of landfill leachate concentrate with a solid content of 30% to 75 parts of concentrated sulfuric acid, adjust the temperature of the reaction system to 155°C for 4.5 hours, filter out the solid matter in the mixed solution and use Repeated washing with distilled water, when the pH of the washed water is neutral, the solid matter can be dried to obtain sulfonated humic acid;

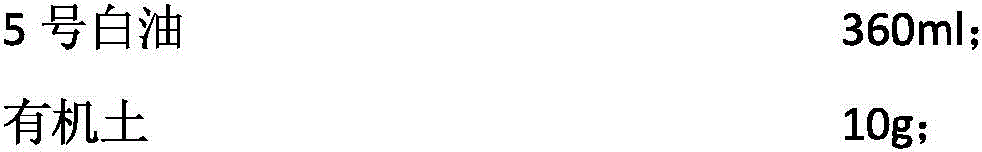

[0036] Step S2: Weigh 200 parts of the sulfonated humic acid prepared above and add it to 85 parts of white oil for dissolution, then add 55 parts of fatty acid amide, and adjust the temperature of the reaction system to 145 ℃ to react for 1h;

[0037] Step S3: Add the reaction product of step S2 together with 80 parts of dibromomethane and 55 parts of epichlorohydrin into the reactor, and carry out the mixed reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com