Core-shell structure quantum dot and preparation method thereof

A technology of core-shell structure and quantum dots, which is applied in the field of core-shell structure quantum dots and its preparation, can solve problems such as difficulty in direct synthesis of large particle size, high stability, difficulty in large-scale production, and decline in quantum yield, so as to slow down the growth rate. Effects of nuclear velocity, good stability, and thick shell thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

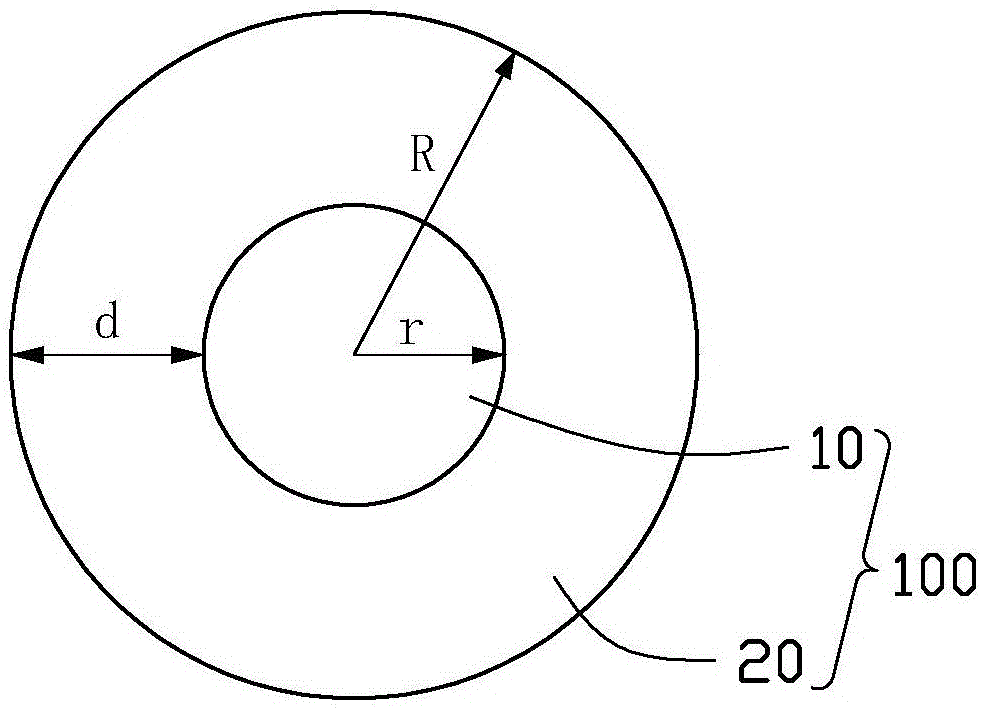

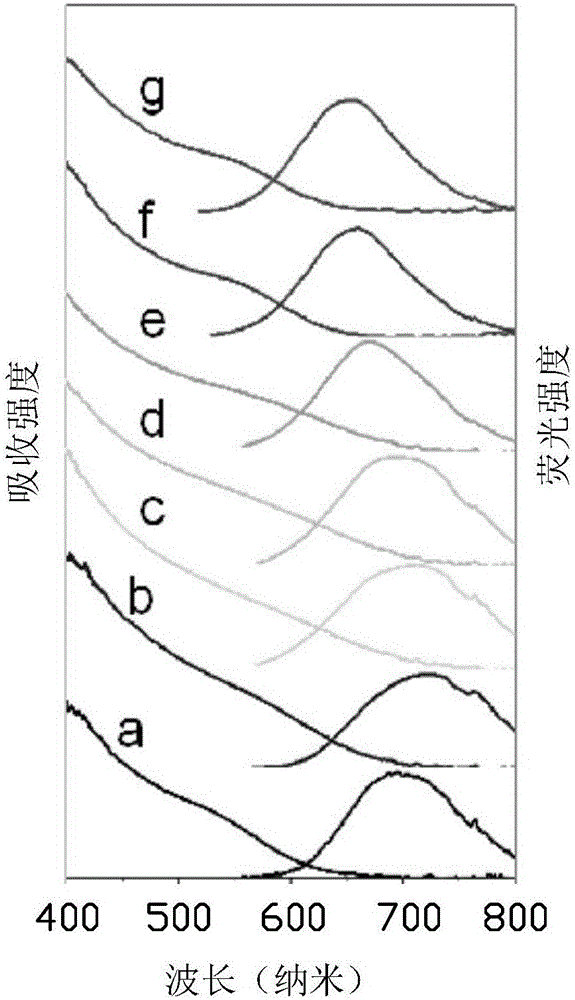

[0037] CuInZn of the first preferred embodiment of the present invention x S 2+x The preparation method of / ZnS (0

[0038] First, a quantum dot nucleus solution is prepared.

[0039] (1) Dissolving copper salt, indium salt and zinc salt in an organic solvent to obtain copper precursor, indium precursor and zinc precursor.

[0040]The copper salt is, for example, but not limited to, copper acetate, copper iodide, copper chloride, copper oleate, copper stearate or combinations thereof. The indium salt is, for example, but not limited to, indium acetate, indium iodide, indium chloride, indium oleate or combinations thereof. The zinc salt is, for example, but not limited to, zinc acetate, zinc oleate, zinc stearate or combinations thereof.

[0041] The organic solvent is, for example, but not limited to liquid paraffin, paraffin, stearyl, oleyl ammonia, oleic acid or combinations thereof.

[0042] In order to reduce the cost of synthesizing quant...

Embodiment 1

[0072] (1) Preparation of quantum dot core CuInZn x S 2+x (x=0.5) solution.

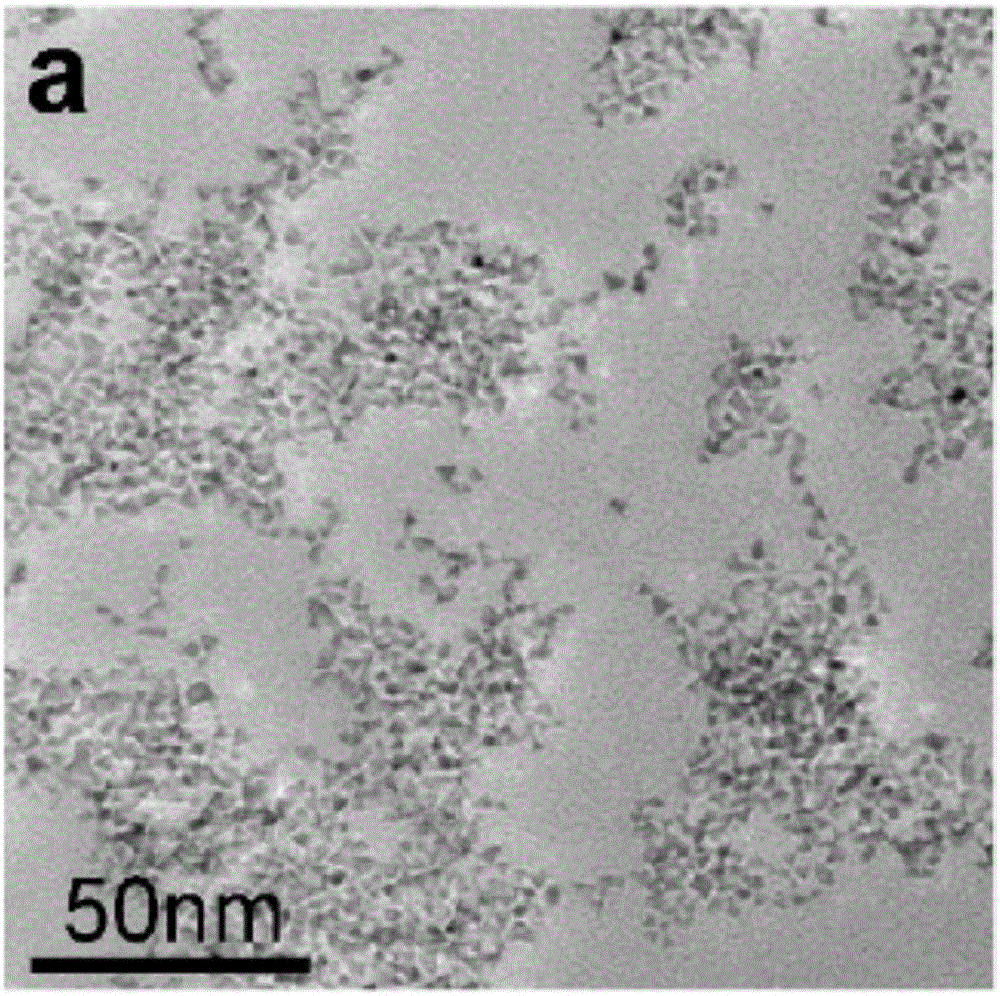

[0073] Mix 0.4mmol copper iodide, 0.4mmol indium acetate and 0.20mmol zinc oleate into a 100mL three-necked flask, then add 10mL liquid paraffin and 1mL oleic acid. Under the protection of nitrogen, exhaust the air at 150 degrees for 10-15 minutes, then add 1 mL of octaalkyl tridentate mercaptan, then rapidly heat to 240 ° C, and react for 10 minutes to obtain CuInZn 0.5 S 2.5 Quantum dot nuclei solution.

[0074] (2) Synthesis and coating of the quantum dot core CuInZn 0.5 S 2.5 quantum dot shell ZnS.

[0075] To the CuInZn 0.5 S 2.5A mixed solution of 5 mL of zinc oleate solution (0.8 mmol / mL, the same below) and 0.5 mL of octaalkyl tridentate mercaptan was added to the quantum dot nucleus solution for the first time. After reacting for 1 hour, a mixed solution of 5 mL of the zinc oleate solution and 0.5 mL of octaalkyl tridentate mercaptan was added for the second time. After reacting fo...

Embodiment 2

[0103] CuInZn of Example 2 x S 2+x / ZnS (x=0.9) preparation method of core-shell structure quantum dots: with reference to the preparation method of embodiment 1, difference is in the synthetic quantum dot core CuInZn 0.9 S 2.9 During the solution process, the molar amount of zinc oleate added was 0.36 mmol, and other parameters were the same. The CuInZn 0.5 S 2.5 The particle size of the / ZnS core-shell quantum dot is about 11.2nm, the thickness of the shell layer is 4.1nm, and the quantum yield is 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com