Luminescent material as well as preparation method and application of luminescent material

A luminescent material, rare earth luminescent technology, applied in luminescent materials, chemical instruments and methods, photovoltaic power generation, etc., can solve the problems of spectral response mismatch, low energy conversion efficiency, and inability to generate carriers, etc., to achieve spectral response matching Good performance, the effect of improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

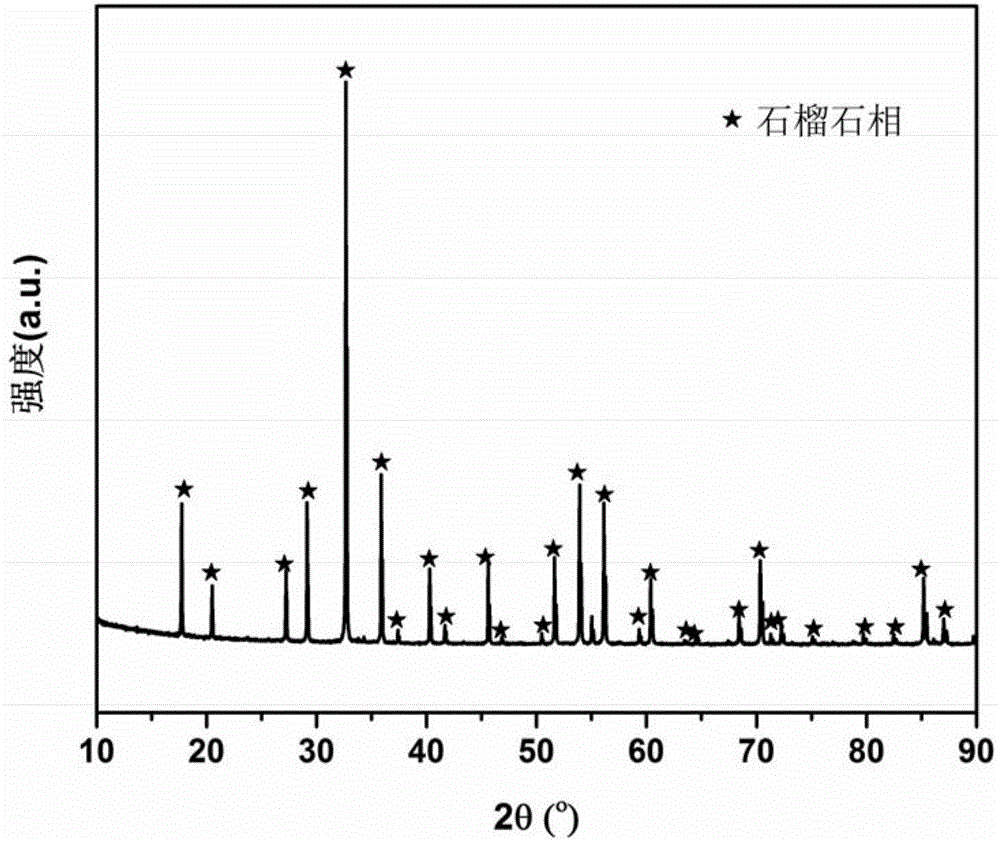

[0056] In this embodiment, the chemical composition molecular formula of the luminescent material is Yb 0.10 Er 0.05 Gd 2.85 Al 2 Ga 3 o 12 .

[0057] The preparation method of the luminescent material powder is as follows:

[0058] (1) Weigh ytterbium oxide, erbium oxide, gadolinium oxide, gallium oxide, and aluminum sulfate according to the stoichiometric ratio of each element, dissolve them in the mixed acid of nitric acid and hydrochloric acid, and make a mixed solution with a concentration of 0.3mol / L A;

[0059] (2) select the mixed alkali of ammoniacal liquor and ammonium bicarbonate as precipitant, add deionized water, be made into the precipitant solution B that concentration is 2mol / L, wherein the mol ratio of ammoniacal liquor and ammonium bicarbonate is 1:4;

[0060] (3) Add the mixed solution A dropwise to the precipitant solution B, accompanied by vigorous mechanical stirring during the dropping process, wherein the dropping speed of the mixed solution A i...

Embodiment 2

[0064] In this embodiment, the chemical composition molecular formula of the luminescent material is Yb 0.10 Er 0.05 Gd 2.85 Al 2 Ga 3 o 12 .

[0065] The preparation method of the luminescent material powder is as follows:

[0066] (1) Weigh ytterbium oxide, erbium oxide, gadolinium oxide, gallium oxide, and aluminum sulfate according to the stoichiometric ratio of each element, dissolve them in the mixed acid of nitric acid and hydrochloric acid, and make a mixed solution with a concentration of 0.3mol / L A;

[0067] (2) select the mixed alkali of ammoniacal liquor and ammonium bicarbonate as precipitant, add deionized water, be made into the precipitant solution B that concentration is 2mol / L, wherein the mol ratio of ammoniacal liquor and ammonium bicarbonate is 1:4;

[0068] (3) The container holding the precipitant solution B is placed in the ultrasonic pool, and then the mixed solution A is added dropwise to the precipitant solution B, so that the dropping process...

Embodiment 3

[0073] In this embodiment, the chemical molecular formula of the luminescent material is Yb 0.15 Er 0.05 Gd 2.8 Al 2 Ga 3 o 12 .

[0074] The preparation method of the luminescent material powder is as follows:

[0075] (1) Weigh ytterbium oxide, erbium oxide, gadolinium oxide, gallium oxide, and aluminum sulfate according to the stoichiometric ratio of each element, dissolve them in the mixed acid of nitric acid and hydrochloric acid, and make a mixed solution with a concentration of 0.3mol / L A;

[0076] (2) select the mixed alkali of ammoniacal liquor and ammonium bicarbonate as precipitant, add deionized water, be made into the precipitant solution B that concentration is 2mol / L, wherein the mol ratio of ammoniacal liquor and ammonium bicarbonate is 1:4;

[0077] (3) The container holding the precipitant solution B is placed in the ultrasonic pool, and then the mixed solution A is added dropwise to the precipitant solution B, so that the dropping process is carried o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Deposition thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com