Compound chelating agent for stabilizing soil heavy metal

A technology of heavy metals and chelating agents, which is applied in the direction of soil conditioning materials, fertilizer mixtures, organic fertilizers, etc., can solve the problems of limited types of heavy metals, increased costs, and difficulty in long-term maintenance, so as to avoid secondary pollution problems, improve stability, good stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

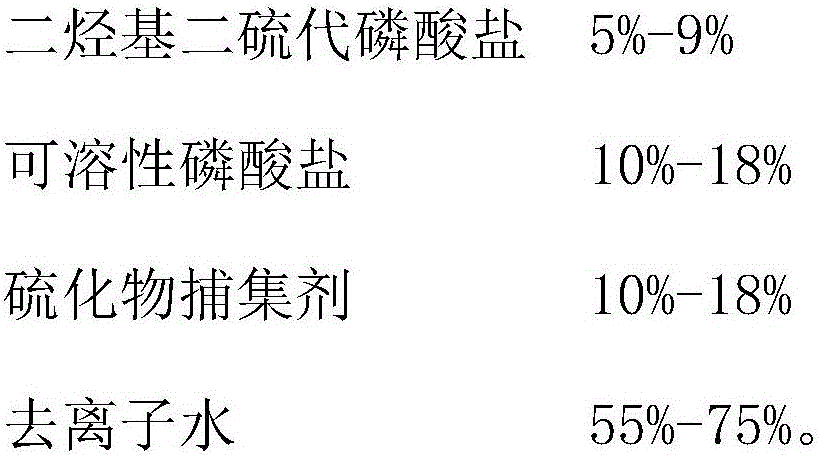

[0020] The present embodiment provides a kind of stable soil heavy metal complex chelating agent, is made by the component mixing of following percentage by weight: 8% dibutyl ammonium dithiophosphate, 16% potassium dihydrogen phosphate, 16% sulfide trapping agent and 60% deionized water.

[0021] In this embodiment, dibutyl ammonium dithiophosphate can also be other dihydrocarbyl disulfides such as ammonium diisopropyl dithiophosphate, potassium dipropyl dithiophosphate, potassium diisopropyl dithiophosphate, etc. Phosphates.

[0022] In this embodiment, potassium dihydrogen phosphate may also be other soluble phosphates such as sodium dihydrogen phosphate, diammonium phosphate, and the like.

[0023] Wherein, the preparation process of the sulfide trapping agent is as follows: step 1, put sulfur and silicic acid in a constant temperature water bath at 25°C, add 20% aluminum sulfate solution by mass percentage, and stir for 0.5h. Step 2: Add sodium hydroxide, raise the temp...

Embodiment 2

[0026] The present embodiment provides a stable soil heavy metal complex chelating agent, which is made by mixing the following components in percentage by weight: 9% ammonium diisopropyl dithiophosphate, 15.5% sodium dihydrogen phosphate, 15.5% sulfide trapping agent and 60% deionized water.

[0027] In this embodiment, diisopropyl ammonium dithiophosphate can also be dibutyl ammonium dithiophosphate, potassium dipropyl dithiophosphate, potassium diisopropyl dithiophosphate and other dihydrocarbyl disulfide Phosphates.

[0028] In this embodiment, sodium dihydrogen phosphate may also be potassium dihydrogen phosphate, diammonium phosphate and other soluble phosphates.

[0029] Wherein, the preparation process of the sulfide trapping agent is as follows: step 1, put sulfur and silicic acid in a constant temperature water bath at 30° C., add aluminum sulfate solution with a mass percentage of 25%, and stir for 1 hour. Step 2: Add sodium hydroxide, raise the temperature to 75°...

Embodiment 3

[0032] The present embodiment provides a kind of stable soil heavy metal complex chelating agent, is made by the component mixing of following percentage by weight: 6% potassium dipropyl dithiophosphate, 17% diammonium phosphate, 17% sulfide trapping agent and 60% %Deionized water.

[0033] In this embodiment, potassium dipropyl dithiophosphate can also be dibutyl ammonium dithiophosphate, ammonium diisopropyl dithiophosphate, potassium diisopropyl dithiophosphate and other dihydrocarbyl disulfide Phosphates.

[0034] In this embodiment, the diammonium phosphate may also be potassium dihydrogen phosphate, sodium dihydrogen phosphate and other soluble phosphates.

[0035] Wherein, the preparation process of the sulfide trapping agent is as follows: step 1, put sulfur and silicic acid in a constant temperature water bath at 27°C, add 22% aluminum sulfate solution by mass percentage, and stir for 0.5h. Step 2: Add sodium hydroxide, raise the temperature to 72° C., stir well to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com