Paracoccus versutus strain and application thereof

A paracoccus and strain technology, applied in bacteria, gas fuels, biochemical equipment and methods, etc., can solve the problems of high economic cost, reducing methane concentration, and difficulty in oxygen regulation, and achieve the effect of avoiding potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

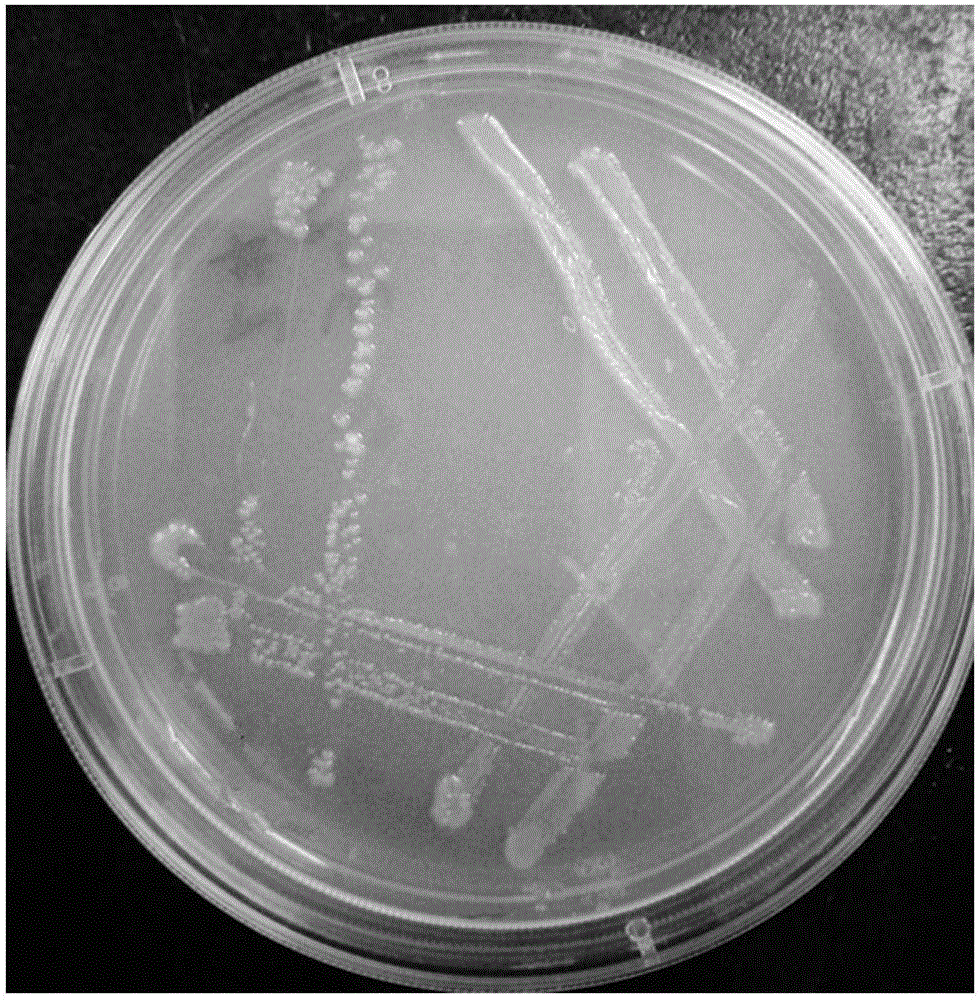

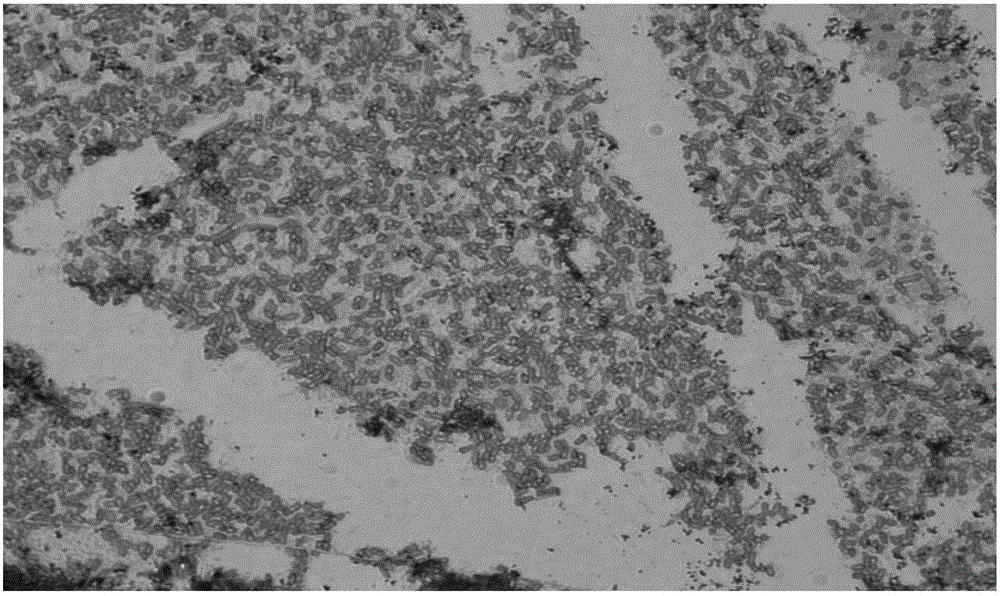

[0031] 1. Isolation and purification of bacterial strains

[0032] The anaerobic sludge was taken from the third sewage treatment plant in Chengdu, Sichuan. The collected sludge was acclimatized with a medium enriched with sulfur compounds under anaerobic conditions, and then serially diluted after 7 days, starting from 10 -2 、10 -4 、10 -6 、10 -8 、10 -10 Draw 0.1ml of the dilution and spread it on the separation medium plate, and a single colony scattered on the surface of the plate appears, pick a single colony, repeat the above operation several times, and finally obtain a solution that can remove H from biogas using nitrate as an electron acceptor. 2 Purified strains of S.

[0033] The enrichment medium is: Na 2 S 2 o 3 ·5H 2 O 5g, KNO 3 4g, KH 2 PO 4 2g, NaHCO 3 1g, MgCl 2 ·6H 2 O 0.5g, FeSO 4 ·7H 2 O 0.01g, pH value 7.0, tap water 1000mL. 121°C, 30min high temperature sterilization. Separation medium: Na 2 S 2 o 3 ·5H 2 O 10g, KNO 3 4g, KH 2 P...

Embodiment 2

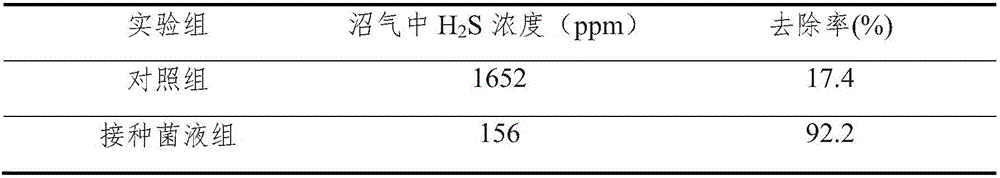

[0045] The present invention paracoccus fimutans strain CGMCC No.13321 is applied to the H in biogas 2 S removed.

[0046] 1. Preparation of culture medium and inoculation solution

[0047] Solid activation medium: Na 2 S 2 o 3 ·5H 2 O 10g, KNO 3 4g, KH 2 PO 4 2g, NaHCO 3 1g, MgCl 2 ·6H 2 O0.5g, FeSO 4 ·7H 2 O 0.01g, 20g agar, 1000mL distilled water, pH7.0-7.5, 121℃, 30min high temperature sterilization. Liquid fermentation medium: Na 2 S 2 o 3 ·5H 2 O 10g, KNO 3 4g, KH 2 PO 4 2g, NaHCO 3 1g, 1000ml tap water, pH7.0-7.5, 121℃, 30min high temperature sterilization treatment. Desulfurization medium: KNO 3 4g, KH 2 PO 4 1g, NaHCO 3 1g, 1000ml tap water, pH7.0-7.5, 121℃, 30min high temperature sterilization treatment.

[0048] Inoculate Paracoccus mutans strain CGMCC No.13321 into the solid activation medium, and activate the culture for 1 day to obtain the activated strain, which is ready for use; put the activated strain into the liquid ferment...

Embodiment 3

[0055] Paracoccus mutans strain CGMCC No.13321 for biogas H 2 S removal, the same as Example 3 will not be repeated, the difference lies in the treatment conditions from the inoculated bacteria solution to the desulfurization reactor.

[0056] The treatment temperature is 20°C, and the H in the biogas is continuously measured 2 The removal rate of S is shown in Table 2 for the measurement results.

[0057] Table 2 Biogas H 2 S removal rate

[0058]

[0059] It can be seen from the above table that the temperature is 20°C, and the biogas H 2 The concentration of S was significantly lower than that of the control group, in which the biogas H 2 The removal rate of S was only 6.2%, while the experimental group biogas H 2 The removal rate of S is as high as 77.1%. Compared with the temperature condition of 30℃, although Paracoccus mutans strain CGMCC No.13321 2 The removal rate of S decreased, but still showed good H 2 S removal effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com