Titanium-iron alloy preparation method

A technology of titanium-iron alloy and vanadium-titanium magnetite, which is applied in the field of preparation of titanium-iron alloy, can solve the problems of large aluminum consumption and high production cost, and achieve the effect of reducing consumption and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

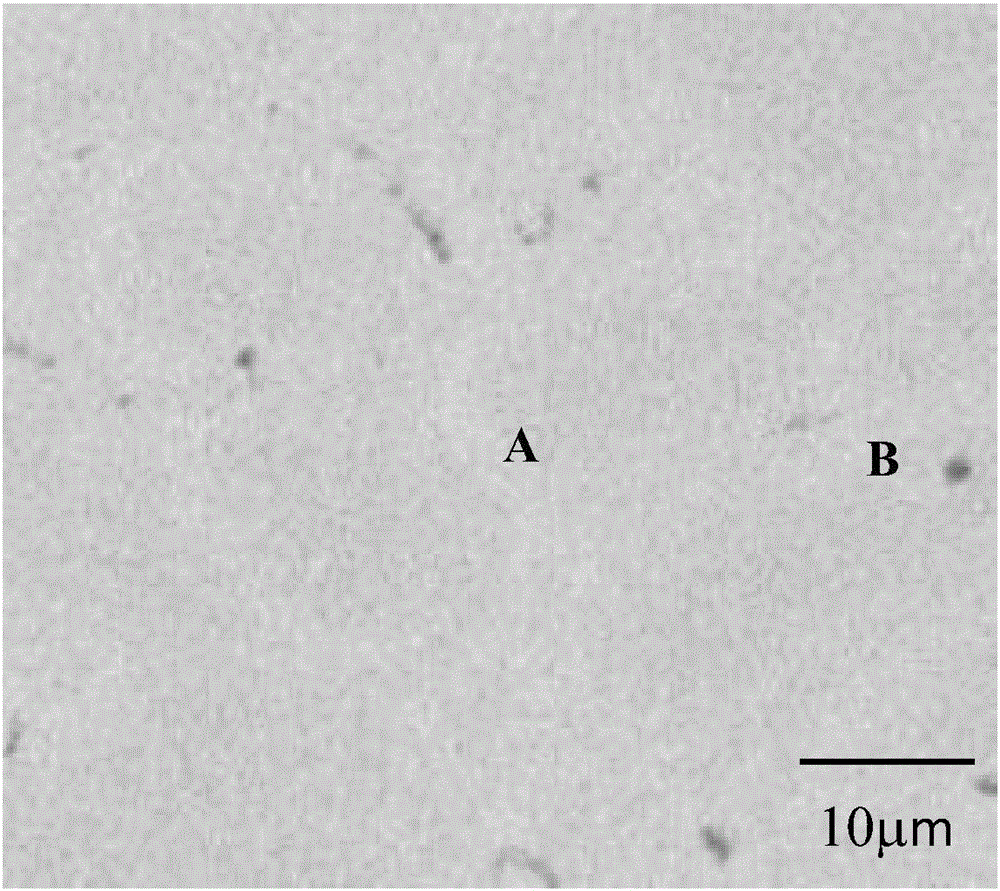

Image

Examples

Embodiment 1

[0022] The preparation method of the ferrotitanium alloy provided by the embodiment of the present invention 1 comprises the following steps:

[0023] (1) Carbothermal reaction

[0024] The vanadium-titanium magnetite is used as the raw material, and the coal powder is used as the reducing agent for mixing. Among them, the vanadium-titanium magnetite and coal powder are mixed according to the carbon ratio of 0.8, and then 1% bentonite is added to the mixture. After that, mix well to form a mixture, mix the mixture with water and make pellets, wherein the mass ratio of the mixture to water is 1:0.08, put the formed wet pellets into a drying oven at 105°C for constant temperature drying, and the drying time is 5 hours. Put the dried balls obtained after drying into a heating furnace for constant temperature heating, the heating temperature is 1200°C, and the heating time is 10 minutes. The heated dry balls are taken out and airtightly cooled, and the cooled dry balls are crushed...

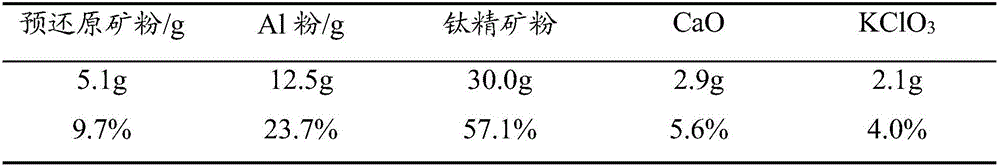

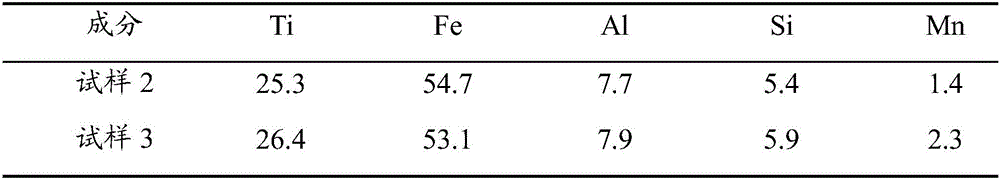

Embodiment 2

[0041] The preparation method of the ferrotitanium alloy provided by the embodiment of the present invention 2 comprises the following steps:

[0042] (1) Carbothermal reaction

[0043] The vanadium-titanium magnetite is used as the raw material, and the coal powder is used as the reducing agent for mixing. Among them, the vanadium-titanium magnetite and coal powder are mixed according to the carbon ratio of 0.8, and then 1% bentonite is added to the mixture. After that, mix well to form a mixture, mix the mixture with water and make pellets, wherein the mass ratio of the mixture to water is 1:0.08, put the formed wet pellets into a drying oven at 105°C for constant temperature drying, and the drying time is 5 hours. Put the dried balls obtained after drying into a heating furnace for constant temperature heating, the heating temperature is 1200°C, and the heating time is 10 minutes. The heated dry balls are taken out and airtightly cooled, and the cooled dry balls are crushed...

Embodiment 3

[0056] The preparation method of the ferrotitanium alloy provided by the embodiment of the present invention 3 comprises the following steps:

[0057] (1) Carbothermal reaction

[0058] The vanadium-titanium magnetite is used as the raw material, and the coal powder is used as the reducing agent for mixing. Among them, the vanadium-titanium magnetite and coal powder are mixed according to the carbon ratio of 0.8, and then 1% bentonite is added to the mixture. After that, mix well to form a mixture, mix the mixture with water and make pellets, wherein the mass ratio of the mixture to water is 1:0.08, put the formed wet pellets into a drying oven at 105°C for constant temperature drying, and the drying time is 5 hours. Put the dried balls obtained after drying into a heating furnace for constant temperature heating, the heating temperature is 1200°C, and the heating time is 10 minutes. The heated dry balls are taken out and airtightly cooled, and the cooled dry balls are crushed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com