Microwave drying control system based on dielectric property dynamic change

A control system, microwave drying technology, applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of lack of, no optimized drying system, uncontrollable drying quality, etc., to prevent insufficient drying or burnt Paste, retain the effect of shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

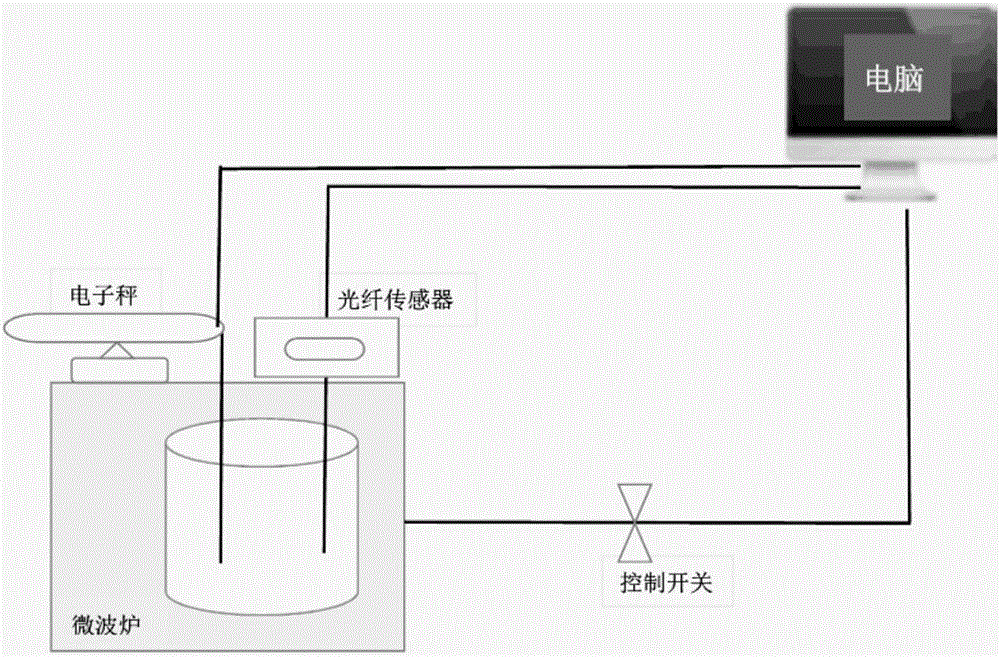

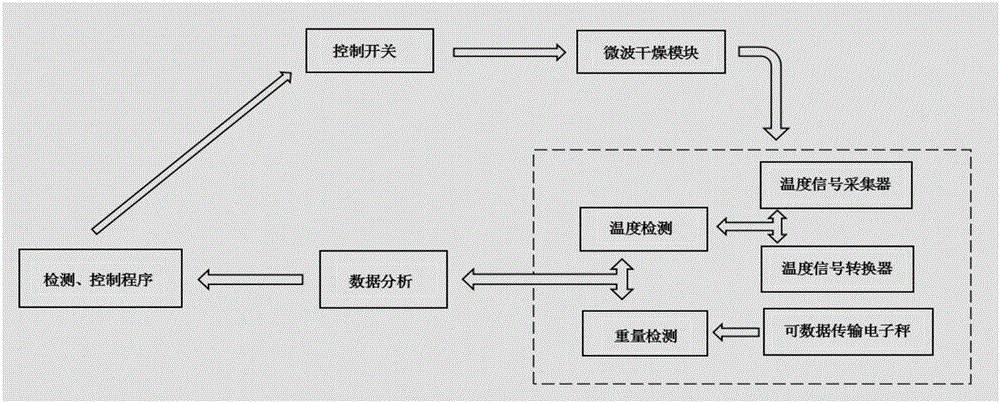

Method used

Image

Examples

Embodiment 1

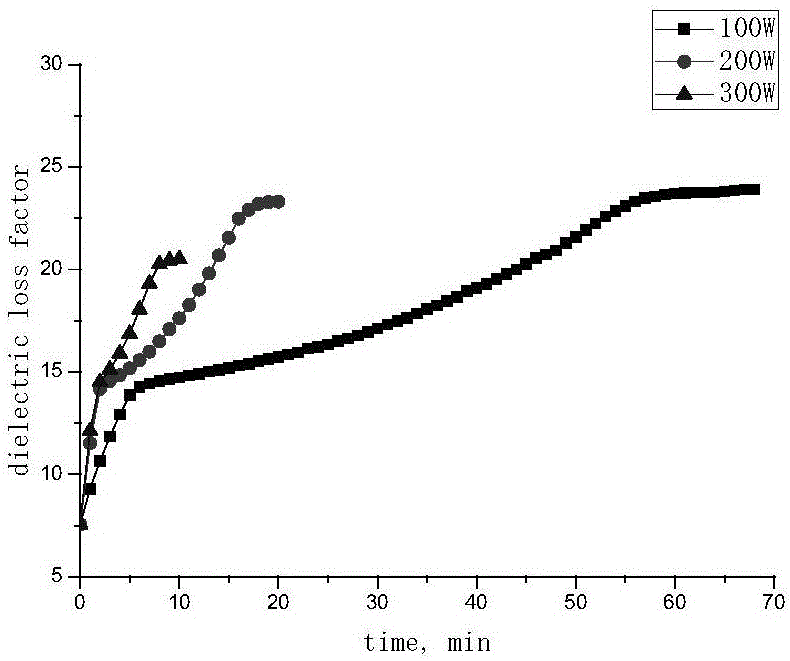

[0040] Embodiment 1: Take Radix Astragali as an example to illustrate the specific operation steps:

[0041] (1) Use network analyzer coaxial cable equipment to measure the dielectric loss factor of Astragalus membranaceus under different moisture conditions (fixed frequency is 2450MHz) with temperature changes. Taking moisture content and temperature as independent variables and dielectric loss factor ε" as dependent variable, the software is used to carry out binary regression fitting on the test data, and the dielectric loss ε" and moisture content and temperature of Astragalus membranaceus at a frequency of 2450 MHz are obtained. Mathematical model for the main influencing factors:

[0042] ε″ 2450-黄芪 =26.3124+0.2332w+0.1645t+0.0065w 2 -0.0004t 2 -0.0056wt

[0043] The relationship between the dielectric loss factor of Astragalus membranaceus and temperature and moisture under the microwave frequency of 2450MHz is as follows: image 3 shown.

[0044] (2) Input the ma...

Embodiment 2

[0047] Embodiment 2: take the ginkgo fruit as an example to illustrate the specific operation steps:

[0048] (1) Use network analyzer coaxial cable equipment to measure the dielectric loss factor of ginkgo fruit under different water conditions, which varies with temperature (fixed frequency is 915MHz). Taking water content and temperature as independent variables, and dielectric loss factor ε" as dependent variable, the software is used to carry out binary regression fitting on the experimental data, and the dielectric loss ε" and water content, water content, and Mathematical model with temperature as the main influencing factor:

[0049] ε″ 915-银杏果 =23.3415+0.0725w+0.2458t-0.0053w 2 +0.0008t 2 -0.0036wt

[0050] The relationship between the dielectric loss factor of ginkgo fruit and temperature and moisture under the microwave frequency of 915MHz is as follows: Figure 4 shown.

[0051] (2) Input the mathematical relationship model between the dielectric loss factor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com