Device and method for treating radioactive organic waste liquid by using supercritical water oxidation

A supercritical water oxidation and organic waste liquid technology, applied in radioactive purification, nuclear engineering, etc., can solve the problems of low safety and public acceptance, difficult equipment design and processing, high maintenance costs, etc., and achieve compact structure and small footprint , The effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

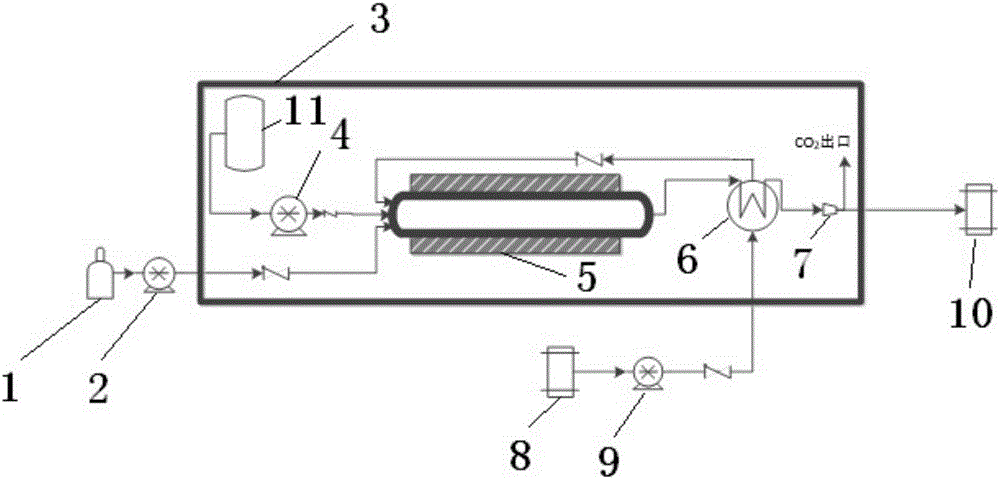

[0040] The present invention will be further described below in conjunction with the drawings and specific embodiments.

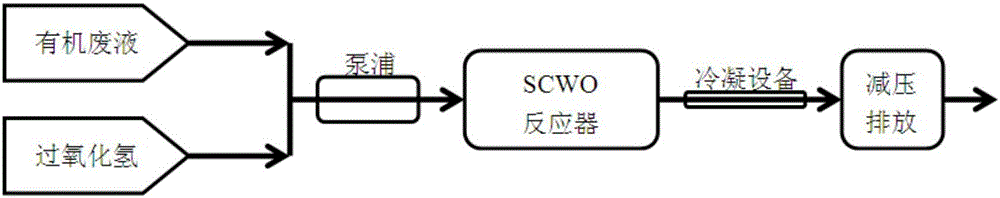

[0041] The main steps of using supercritical water oxidation method to treat radioactive organic waste are as follows:

[0042] Step (1), configure the required oxygen source (hydrogen peroxide, high purity oxygen or O 3 Etc.), in line with the required oxygen mass fraction ratio in the process of oxidizing organic matter;

[0043] Step (2), carry out related treatment of organic waste (to meet the normal injection of high-pressure pump), this step will be different according to the different treatment methods of the treated material, but its ultimate goal is to allow the normal injection of organic material;

[0044] Step (3): Calculate the pump speed v under the corresponding conditions according to the residence time t required for each reaction, the relevant reactor volume and the oxygen mass fraction ratio;

[0045] Step (4), start to adjust the speed of the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com