Gallium nitride PN junction realized by injecting fluorine ions and manufacturing method of gallium nitride PN junction

A manufacturing method and technology of fluoride ions, which are applied in semiconductor/solid-state device manufacturing, electrical components, diodes, etc., can solve difficult problems, and achieve low cost, precise and controllable concentration and depth distribution, and high doping uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

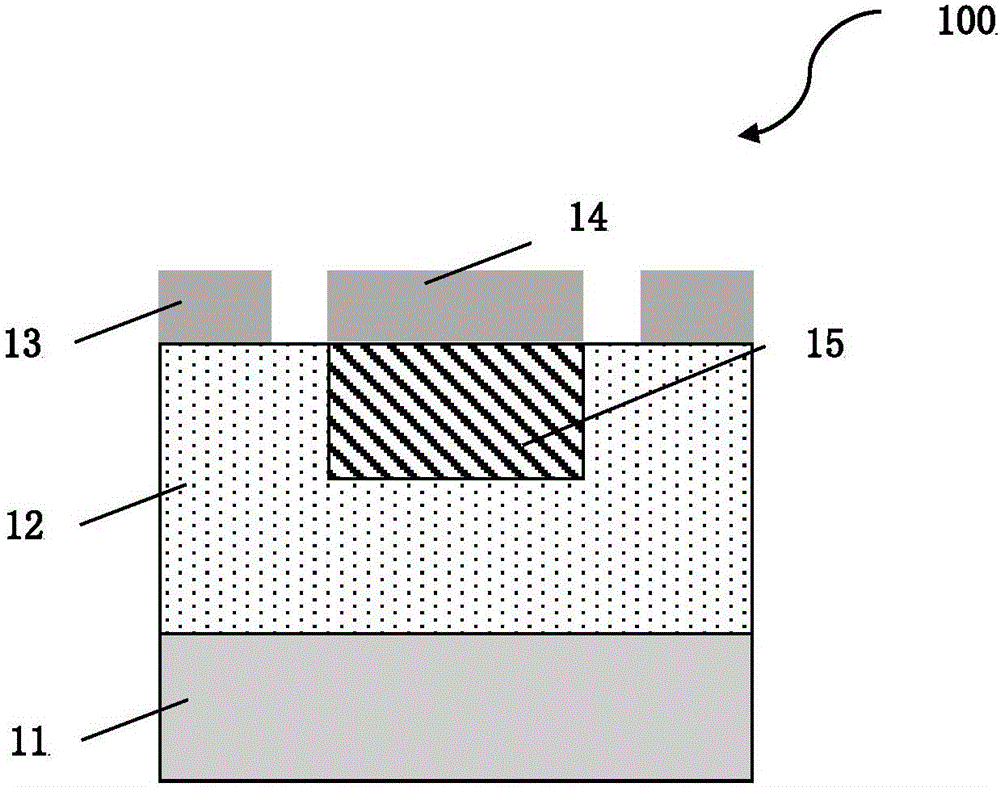

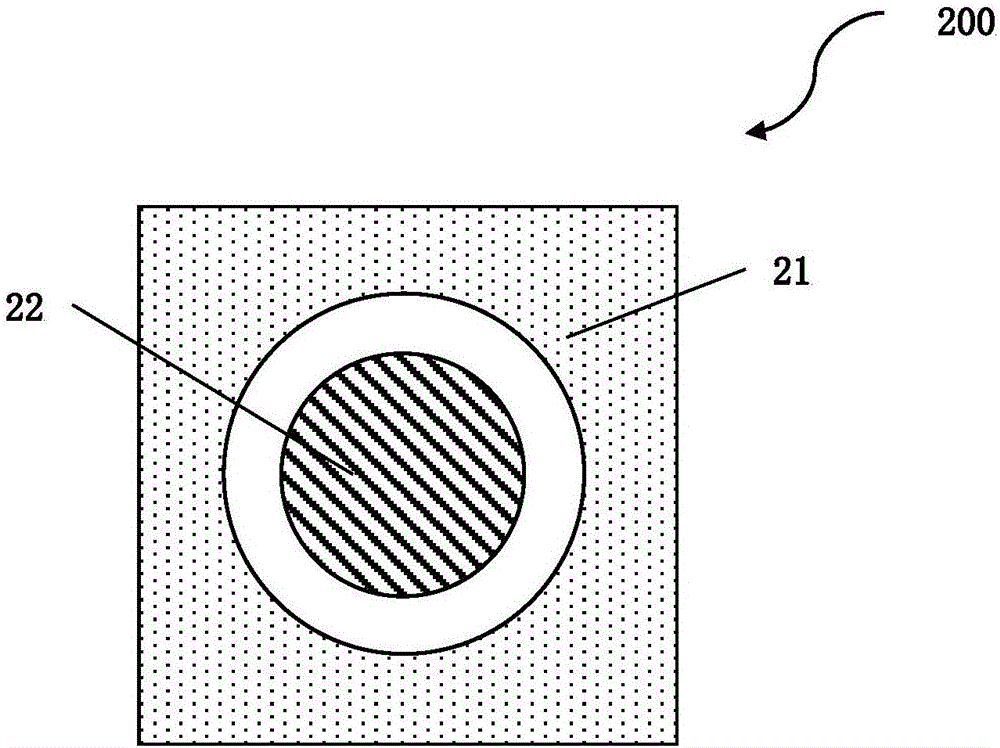

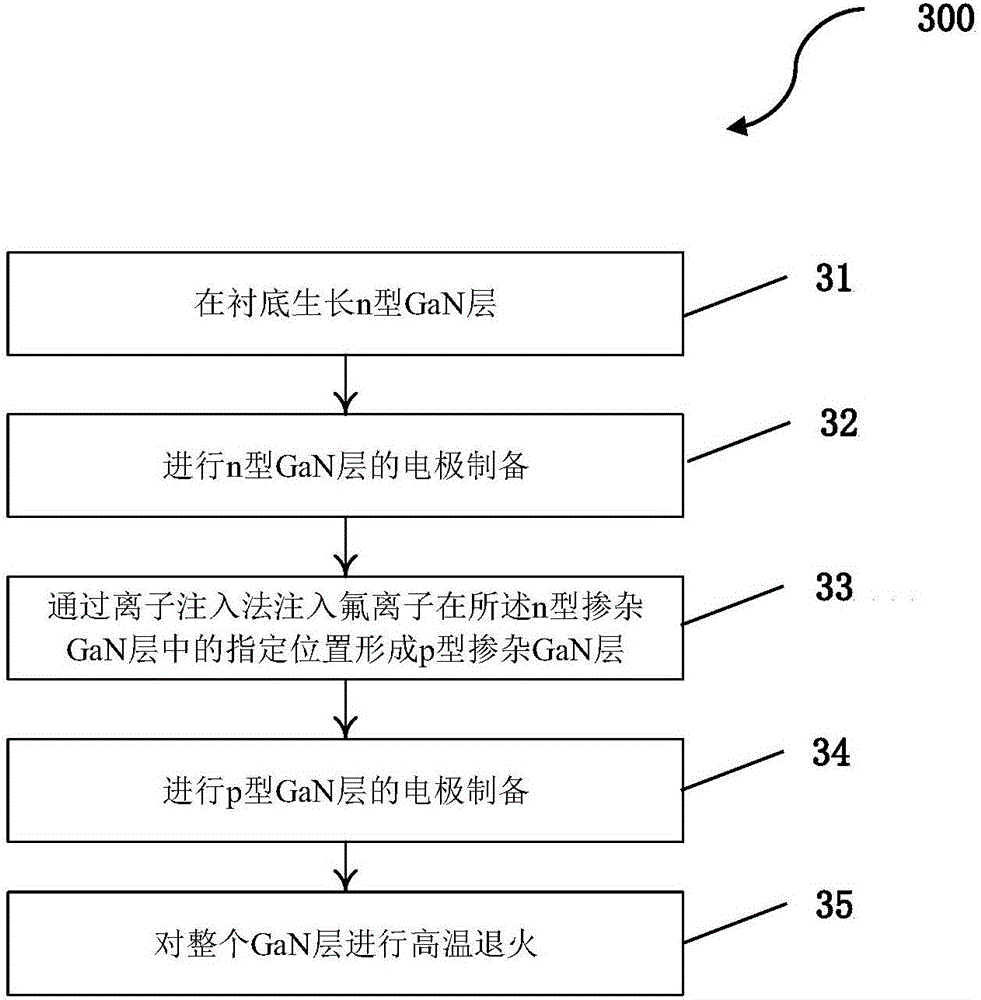

[0040] The drawings in the present invention are all schematic diagrams, mainly intended to represent the manufacturing process steps and the upper-lower sequence relationship between each layer, and the shapes, thicknesses and widths are not drawn to scale.

[0041] figure 1 An embodiment of the invention is shown. This embodiment illustrates a schematic cross-sectional view of a manufacturing method of a GaN-based PN junction 100 realized by fluorine ion implantation. First, a substrate 11 is provided, such as but not limited to a silicon (silicon, Si) substrate, a sapphire substrate, or an unintentionally doped gallium nitride (gallium nitride, GaN) substrate. On the substrate 11 , an n-type GaN semiconductor layer 12 is grown by, for example but not limited to, epitaxial technology. Next, fluorine ions are implanted into the middle region of the n-type GaN semiconductor layer 12 by ion implantation technology to form the p-type GaN semiconductor layer 15 . Wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com