LED light source used for aquiculture

An LED light source and aquaculture technology, applied in the field of optoelectronics, can solve the problems of the light source not being suitable for green environmental protection, energy saving and emission reduction, etc., and achieve the effect of convenient light source ratio and photoperiod, small absorption coefficient, and regulation of light source ratio and photoperiod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh the green fluorescent powder and powder mixing glue according to the ratio of 1:6 and mix them evenly, vacuumize the mixed slurry with a vacuum degassing machine, and obtain the fluorescent powder slurry after removing air bubbles;

[0038] Clean the surface of the blue LED chip with a plasma cleaning machine, apply the phosphor powder slurry directly on the surface of the LED chip by dispensing, put it in a drying oven and heat (150°C) for 2 hours to obtain a cured phosphor layer;

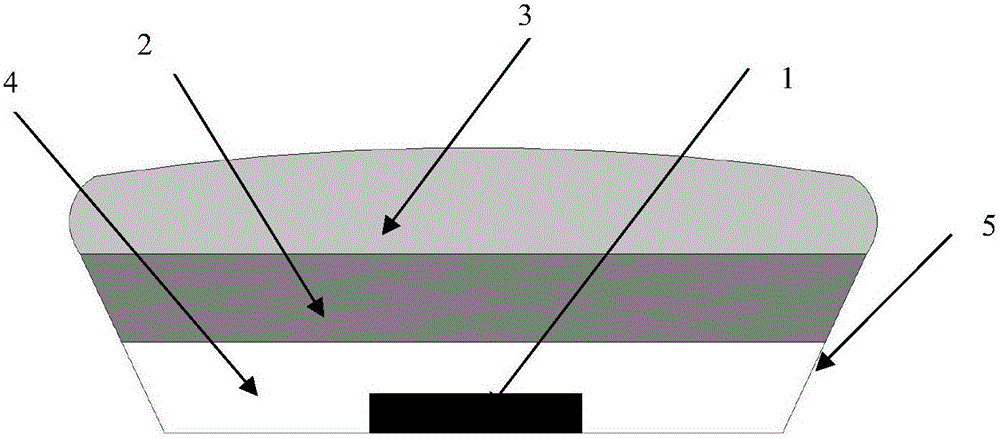

[0039] Then use the glue dispensing method to evenly coat a specific shape of silica gel on the phosphor layer as a light-transmitting layer, and then heat (120°C) in a drying oven to cure for 2 hours to obtain a light-transmitting layer;

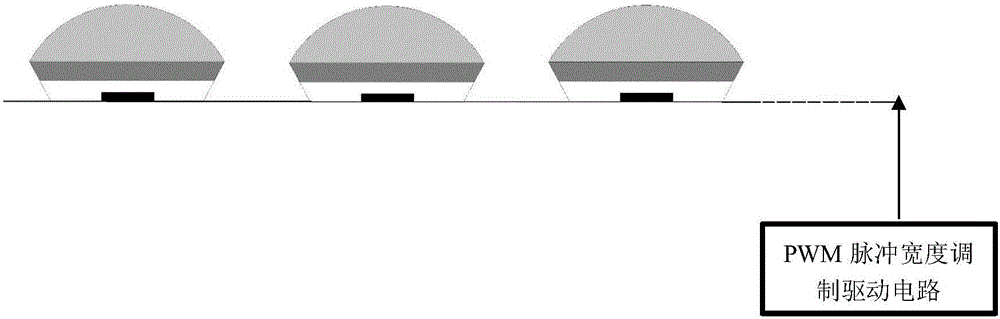

[0040] Finally, the light intensity of a group of LED chips is adjusted through the PWM pulse width modulation driving circuit.

Embodiment 2

[0042] Weigh the green fluorescent powder and powder mixing glue according to the ratio of 1:6 and mix them evenly, vacuumize the mixed slurry with a vacuum degassing machine, and obtain the fluorescent powder slurry after removing air bubbles;

[0043] Clean the surface of the blue LED chip with a plasma cleaning machine, apply the phosphor powder slurry directly on the surface of the LED chip by dispensing, put it in a drying oven and heat (150°C) for 2 hours to obtain a cured phosphor layer;

[0044] Cover the above-mentioned LED chip with a hemispherical lens cap, pour silica gel into the inside, and then heat (120°C) in a drying oven for 2 hours to obtain a light-transmitting layer;

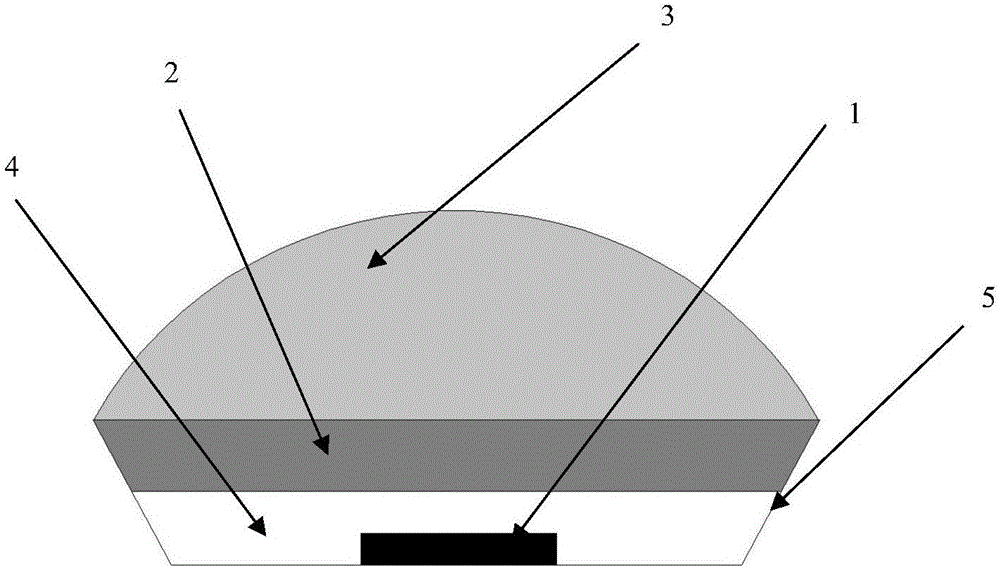

[0045] The resulting LED chip structure is as figure 1 As shown, the light intensity of a group of LED chips is adjusted through the PWM pulse width modulation driving circuit.

Embodiment 3

[0047] Weigh the green fluorescent powder and powder mixing glue according to the ratio of 1:6 and mix them evenly, vacuumize the mixed slurry with a vacuum degassing machine, and obtain the fluorescent powder slurry after removing air bubbles;

[0048] Use a plasma cleaning machine to clean the surface of the blue LED chip. First, use a spray gun to evenly spray a certain thickness of silica gel on the light-emitting surface of the LED chip as a carrier layer, then coat the phosphor powder slurry on the carrier layer, and heat it in a drying oven (150°C ) was dried for 2 hours to obtain a cured phosphor layer;

[0049] Cover the above-mentioned LED chip with a hemispherical lens cap, pour silica gel into the inside, and then heat (120°C) in a drying oven for 2 hours to obtain a light-transmitting layer;

[0050] The resulting LED chip structure is as figure 1 As shown, the light intensity of a group of LED chips is adjusted through the PWM pulse width modulation driving circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com