Preparation method of anthracene-doped polyphenyl acetylene-graphene OLED (organic light emitting diode) photoelectric particles

A poly-p-phenylene vinylene and graphene technology, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of increased device series resistance, influence of electronic transport performance, and electronic defect obstruction, etc., to achieve long life and reduce fluorescence. Quenching, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

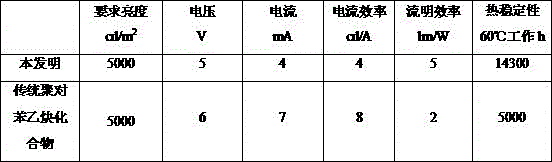

Examples

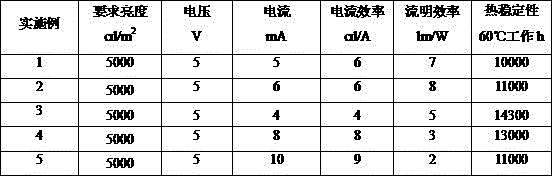

Embodiment 1

[0029] (1) Mix and disperse 8 parts by mass of flake graphite powder, 1 part by mass of graphene quantum dots and 61 parts by mass of poly(p-phenylene vinylene) in a high-speed mixer at a speed of 1200 rpm for 10 minutes to obtain a premix;

[0030] (2) Add 30 parts by mass of organic compounds containing anthracene groups and their derivatives into toluene to prepare a solution of organic compounds containing anthracene groups at a concentration of 0.5 mol / L, and mix the premix obtained in step (1) with The organic matter solution of the anthracene group is mixed, stirred, and the stirring speed is 600 rpm, poured into a square or cylindrical mold after being fully stirred, and left to stand until there is no bubble, to obtain a mixed solution;

[0031] (3) The mixed solution in step (2) is subjected to low-temperature freezing treatment, and the temperature of the low-temperature freezing treatment is set to -25°C, and the frozen solid mixture is added to a grinder for grindi...

Embodiment 2

[0034] (1) 8 parts by mass of dense crystalline graphite powder, 0.5 parts by mass of graphene oxide quantum dots and 65 parts by mass of poly(p-phenylene vinylene) were mixed and dispersed in a high-speed mixer at a speed of 600 rpm for 25 minutes to obtain a premix;

[0035] (2) Add 26.5 parts by mass of organic substances containing anthracene groups and their derivatives into chloroform to prepare a solution of organic substances containing anthracene groups at a concentration of 0.7mol / L, and mix the premix obtained in step (1) with The organic matter solution of the anthracene group is mixed, stirred, and the stirring speed is 600 rpm, poured into a square or cylindrical mold after being fully stirred, and left to stand until there is no bubble, to obtain a mixed solution;

[0036] (3) The mixed solution in step (2) is subjected to low-temperature freezing treatment, and the temperature of the low-temperature freezing treatment is set to -20°C. After the frozen solid mixt...

Embodiment 3

[0039] (1) 10 parts by mass of dense crystalline graphite powder, 3 parts by mass of graphene oxide quantum dots and 37 parts by mass of poly(p-phenylene vinylene) were mixed and dispersed in a high-speed mixer at a speed of 800 rpm for 20 minutes to obtain a premix;

[0040] (2) Add 50 parts by mass of organic compounds containing anthracene groups and their derivatives into chloroform to prepare a solution of organic compounds containing anthracene groups at a concentration of 0.3mol / L, and mix the premix obtained in step (1) with The organic matter solution of the anthracene group is mixed, stirred, and the stirring speed is 400 rpm, poured into a square or cylindrical mold after being fully stirred, and left to stand until there is no bubble, to obtain a mixed solution;

[0041] (3) The mixed solution in step (2) is subjected to low-temperature freezing treatment, and the low-temperature freezing treatment temperature is set to -30°C, and the frozen solid mixture is added t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com