Preparation method of double-layer porous carbon nanofibers for lithium-sulfur batteries and method for preparing positive electrode materials using the same

A lithium-sulfur battery and nanofiber technology, applied in battery electrodes, nanotechnology, circuits, etc., can solve problems such as poor structural stability, and achieve the effects of alleviating volume changes, excellent conductive channels, and inhibiting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

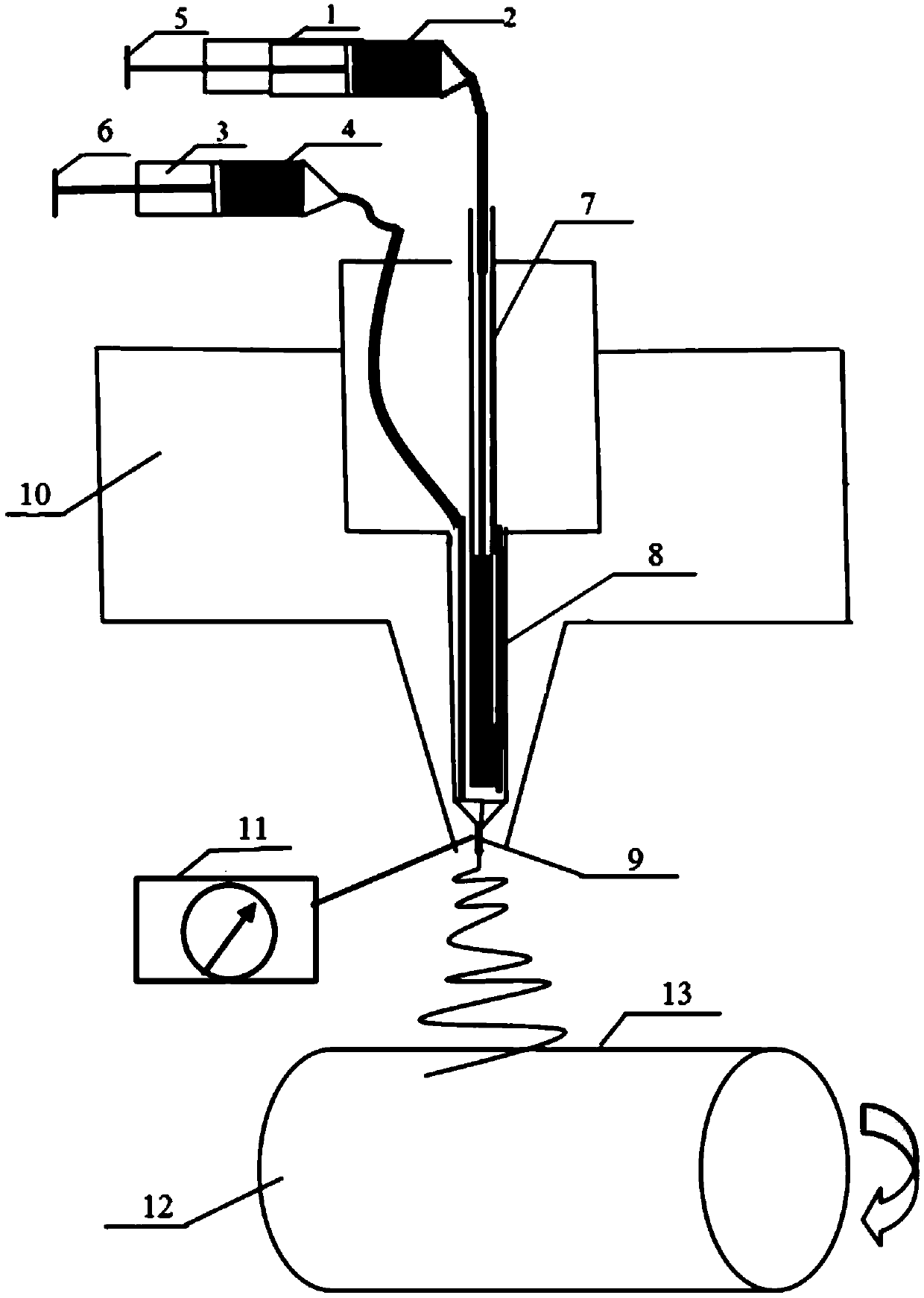

[0036] A preparation method for double-layer porous carbon nanofibers for lithium-sulfur batteries, comprising the steps of:

[0037] 1) Using airflow coaxial electrospinning, the core layer spinning solution and the cortex spinning solution are extruded from the coaxial electrospinning needle at the same time, under the action of high-speed airflow and electrostatic voltage, to the receiving net; Structured nanoscale primary fibers;

[0038] Wherein the core layer spinning solution is obtained by the following steps: 35wt% polyacrylonitrile (PAN) (Mw=150,000, Aldrich), 13wt% porogenic polymer PS are dissolved in 52wt% N,N-dimethylformaldehyde In the amide, continuously stirred at 70°C for 24 hours, and ultrasonically oscillated for 12 hours to obtain a uniform PAN / PS solution;

[0039] Wherein the cortex spinning solution is obtained by the following steps: 38wt% polyacrylonitrile (PAN) (Mw=150,000, Aldrich), 4wt% zinc acetate (Mw=220, Aldrich) are dissolved in 58wt% N,N-di ...

Embodiment 2~5

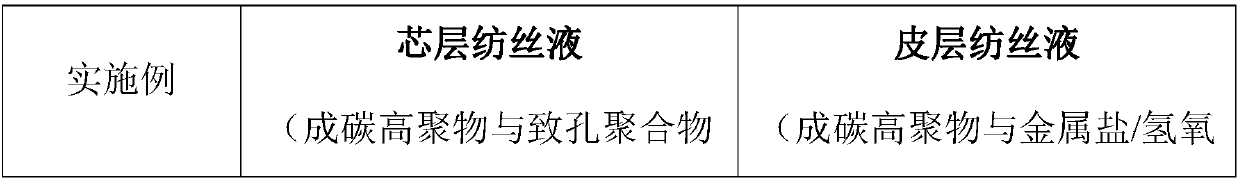

[0053] On the basis of Example 1, the compositions of the skin layer spinning solution and the core layer spinning solution (as shown in Table 1) were respectively changed to prepare double-layer porous carbon nanofibers for lithium-sulfur batteries.

[0054] Using the double-layer porous carbon nanofibers prepared in each example, the positive electrode material was prepared in the same way as in Example 1, and then the battery was assembled according to the method in Example 1, and performance tests were performed. The results are shown in Table 3.

[0055] Table 1

[0056]

[0057]

Embodiment 6~8

[0059] On the basis of Example 1, only the composition of the core layer spinning solution (as shown in Table 2) was changed to prepare double-layer porous carbon nanofibers for lithium-sulfur batteries.

[0060] Using the double-layer porous carbon nanofibers prepared in each example, the positive electrode material was prepared in the same way as in Example 1, and then the battery was assembled according to the method in Example 1, and performance tests were performed. The results are shown in Table 3.

[0061] Table 2

[0062]

[0063]

[0064] table 3

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com