Electrolyte for lithium ion battery

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of battery flatulence, low electrolyte functionality and stability, and long penetration time of positive electrode and negative electrode. , to achieve the effect of improving stability and functionality, improving wettability and compatibility, and improving high-rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

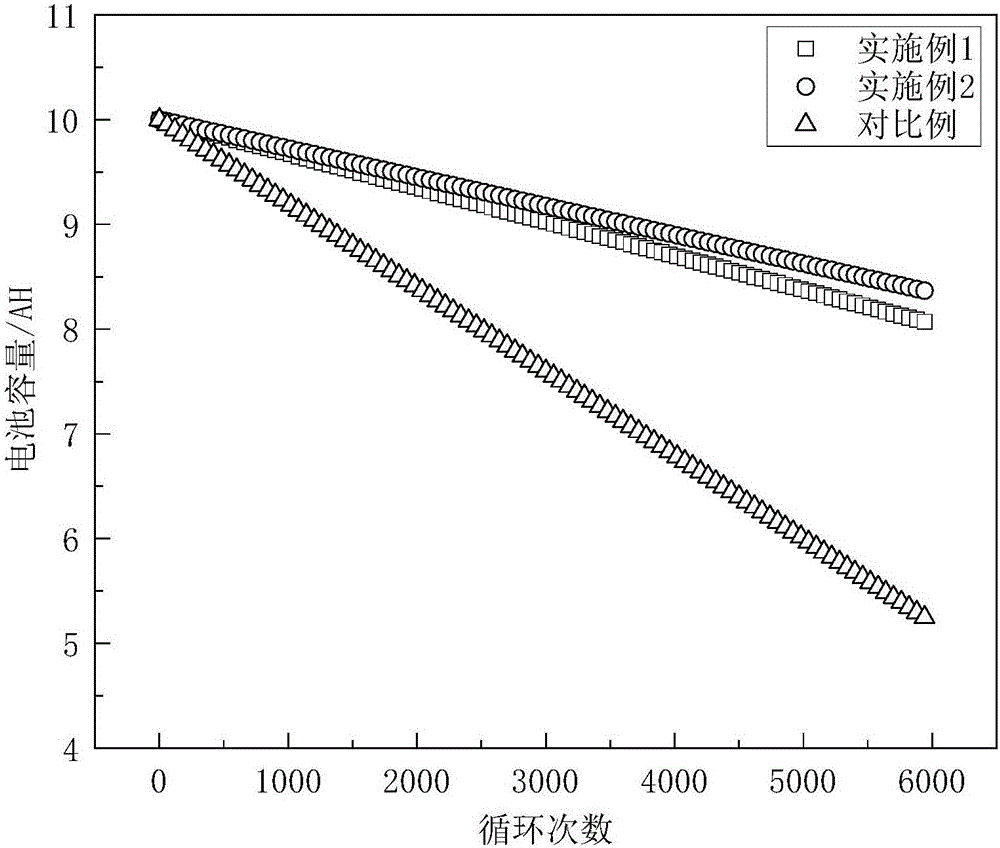

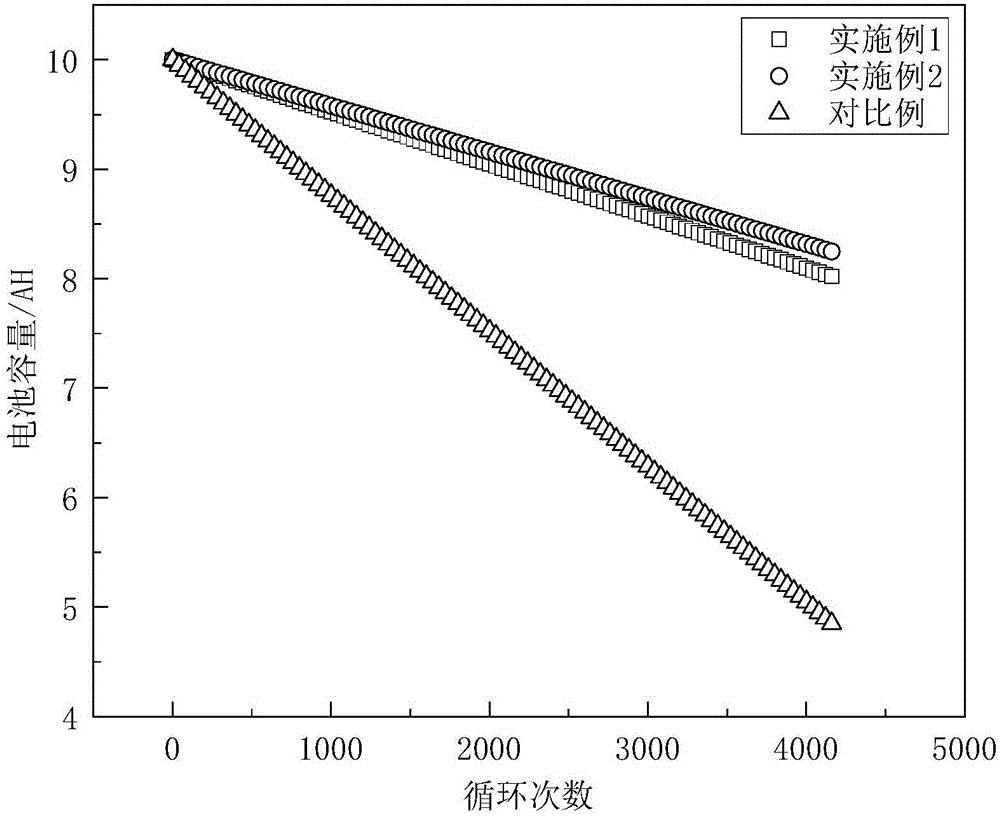

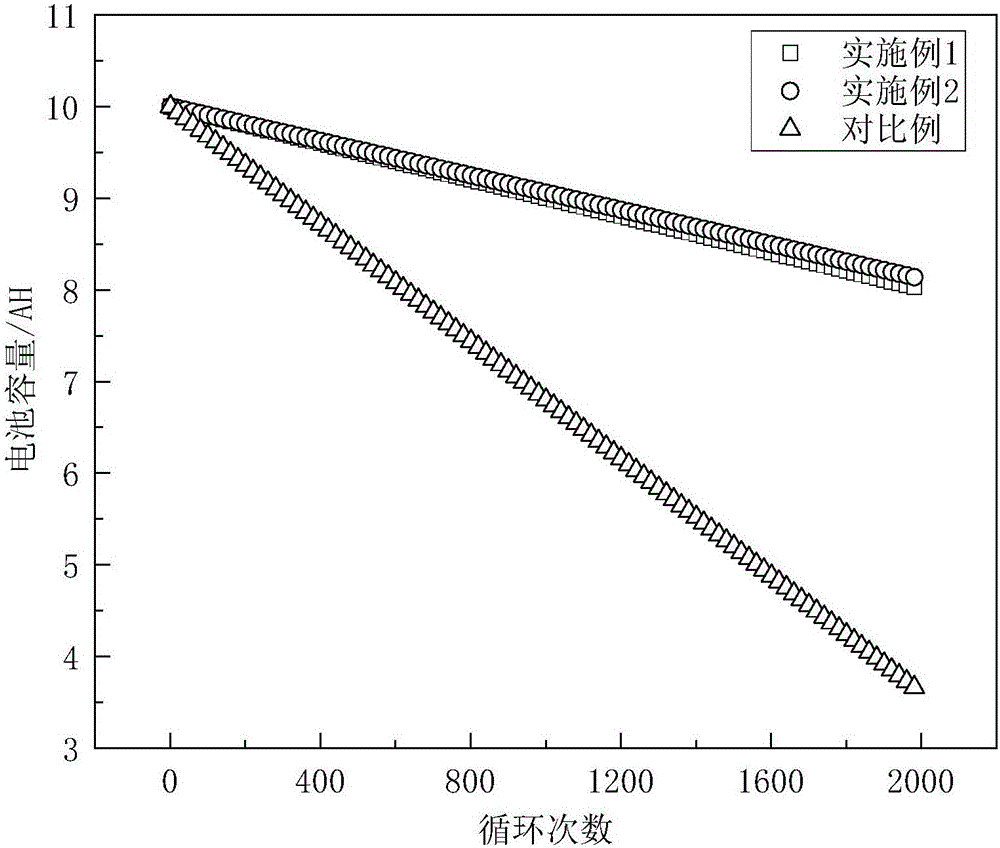

Embodiment 1

[0064] By weight percentage, get 5.0% propylene carbonate, 10.0% dibutyl carbonate, 20.0% ethylene carbonate, 20.0% ethyl butyl carbonate and 25.0% ionic liquid respectively, in the glove box with humidity less than 8ppm, the above solution is mechanically Stir and mix evenly, the solution temperature is controlled at 25±2°C, and the solvent for the electrolyte is prepared; add 10.0% lithium hexafluorophosphate to the solvent, and after it is completely dissolved, continue to add 2.0% heptamethyldisilazane, 4.0% vinyl vinylene carbonate and 4.0% N,N-dimethyltrifluoroacetamide were stirred and mixed evenly, and after standing for 24 hours, the electrolyte solution of the lithium titanate lithium ion battery of this embodiment was obtained.

[0065] The anion of the ionic liquid in this embodiment is

[0066]

[0067] Cation is

[0068] Among them, R 12 for CH 3 CH 2 -, R 13 for CH 3 CH 2 -, R 14 for CH 3 BrCH-, R 15 for CH 3 CH 2 CH 2 CH 2 CH 2 -, R 16 for ...

Embodiment 2

[0070]In percent by weight, respectively take 10.0% fluorine-containing carbonate, 10.0% propylene carbonate, 10.0% dibutyl carbonate, 10.0% ethylene carbonate, 20.0% ethyl butyl carbonate and 20.0% ionic liquid, in the humidity less than 8ppm In the glove box, the above solution was mechanically stirred and mixed evenly, and the temperature of the solution was controlled at 25±2°C to prepare a solvent for the electrolyte; 10.0% lithium hexafluorophosphate was added to the solvent, and after it was completely dissolved, 2.0% lithium hexafluorophosphate was continued to be added to the solvent. Methyldisilazane, 4.0% vinyl vinylene carbonate and 4.0% N,N-dimethyltrifluoroacetamide were stirred and mixed uniformly, and the lithium titanate lithium ion battery of this embodiment was obtained after standing for 24 hours of electrolyte.

[0071] The anion of the ionic liquid in this embodiment is

[0072]

[0073] Cation is

[0074] Among them, R 1 for CH 3 CHFCH 2 -, R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com