Forward switching power supply

A switching power supply and forward excitation technology, applied in electrical components, regulating electrical variables, instruments, etc., can solve the problems of low current density, troublesome winding of primary windings, low efficiency of switching power supply, etc., to achieve high conversion efficiency, EMI good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

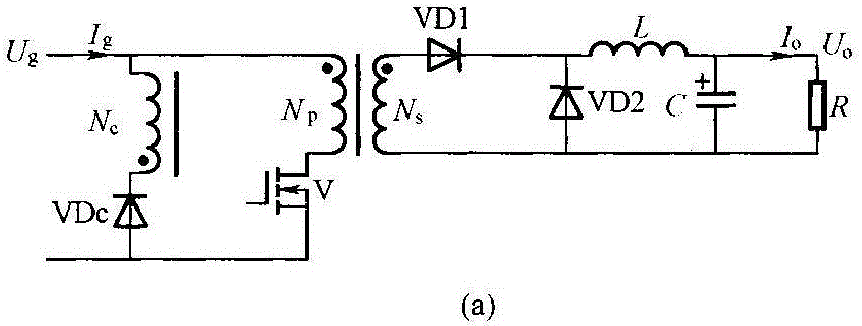

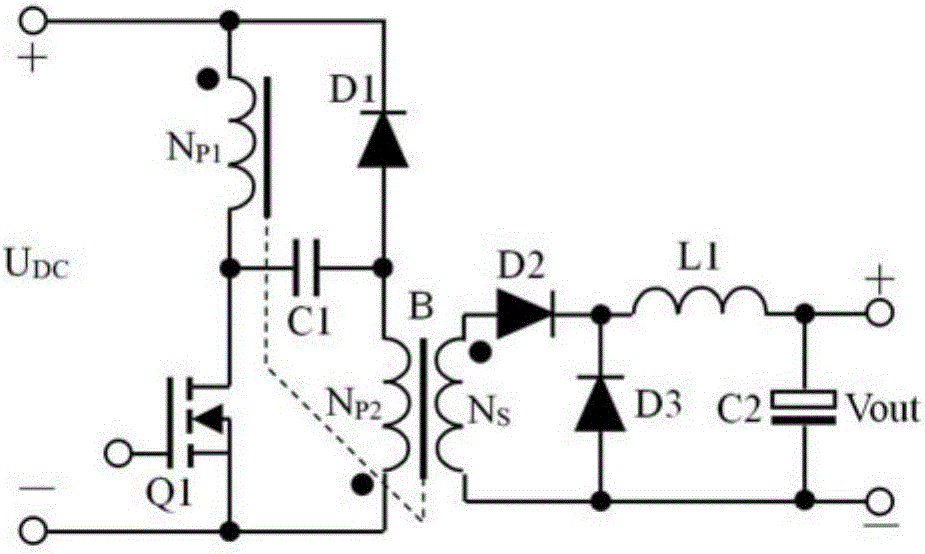

no. 1 example

[0037] figure 1 It shows the schematic diagram of the forward switching power supply of the first embodiment of the present invention, including a transformer B, an N-channel field effect transistor Q1, a second capacitor C2, a first diode D1, a second diode D2, The third diode D3, the first inductor L1, the transformer B includes the first primary winding N P1 , the second primary winding N P2 and the secondary winding N S , secondary winding N S The terminal with the same name is connected to the anode of the second diode D2, and the cathode of the second diode D2 is connected to the cathode of the third diode D3 and one end of the first inductor L1 at the same time, and the other end of the first inductor L1 is connected to the second capacitor C2 One end is connected and forms the output positive, which is the + end of Vout in the figure, and the secondary winding N S The opposite end is connected with the anode of the third diode D3 and the other end of the second ca...

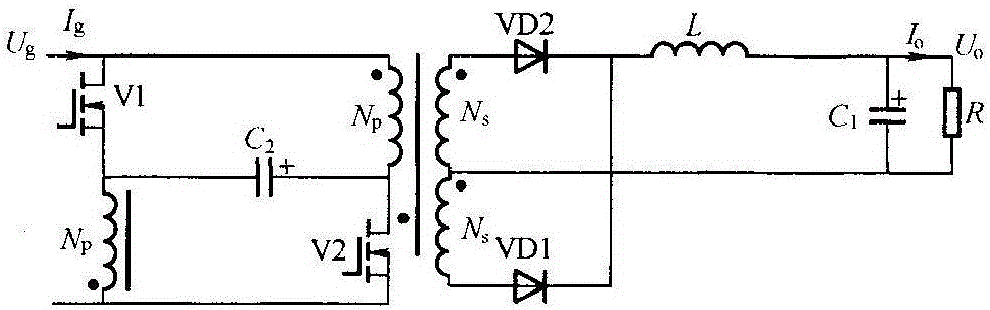

no. 2 example

[0063] The present invention also provides an equivalent solution to the above-mentioned first embodiment, corresponding to solution 2, see figure 2 , a forward switching power supply, including a transformer B, an N-channel field effect transistor Q1, a second capacitor C2, a first diode D1, a second diode D2, a third diode D3, a first inductor L1, transformer B includes the first primary winding N P1 , the second primary winding N P2 and the secondary winding N S , secondary winding N S The terminal with the same name is connected to the anode of the second diode D2, and the cathode of the second diode D2 is connected to the cathode of the third diode D3 and one end of the first inductor L1 at the same time, and the other end of the first inductor L1 is connected to the second capacitor C2 One end is connected and forms the output positive, which is the + end of Vout in the figure, and the secondary winding N S The opposite end is connected with the anode of the third d...

no. 2 example

[0074] In the second example, the demagnetization circuit consists of D1 and the second primary winding N P2 Composition, the working principle is:

[0075] At the moment when Q1 is turned off and after that, the energy of the excitation current is not transferred to the secondary side, and the second primary winding N P2 The electric energy of the medium excitation current, its current direction is the same as that of the excitation, flows from the end with the same name to the end with the same name, flows from bottom to top, turns on D1, and this electric energy is absorbed by the DC power supply U DC Absorption, forming the excitation current demagnetization current loop;

[0076] Similarly, the first primary winding N P1 The electrical energy of the medium excitation current is coupled to the second primary winding N through no leakage inductance P2 In , the demagnetization is realized through D1, which also forms the demagnetization current loop of the excitation curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com