Preparation method of nanometer cadmium oxide with special shape

A technology of cadmium oxide and cadmium hydroxide, which is applied in the field of nanomaterials, can solve problems such as affecting chemical properties, morphology damage, product structure collapse, etc., and achieve the effects of low reaction temperature, smooth surface and stable powder properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, a kind of preparation method of the special appearance nanometer cadmium oxide of high catalytic performance, comprises steps as follows:

[0042] (1) Weigh 0.7712g (2.5mmol) of cadmium nitrate tetrahydrate and dissolve it in 50mL of absolute ethanol to form a cadmium nitrate ethanol solution. Weigh 0.2623g (6.25mmol) of lithium hydroxide and dissolve it in 20mL of double-distilled water to form a lithium hydroxide solution.

[0043] Under the condition of stirring, the lithium hydroxide solution was added dropwise to the cadmium nitrate ethanol solution, and after the dropwise addition was completed, the stirring was continued for 60 min.

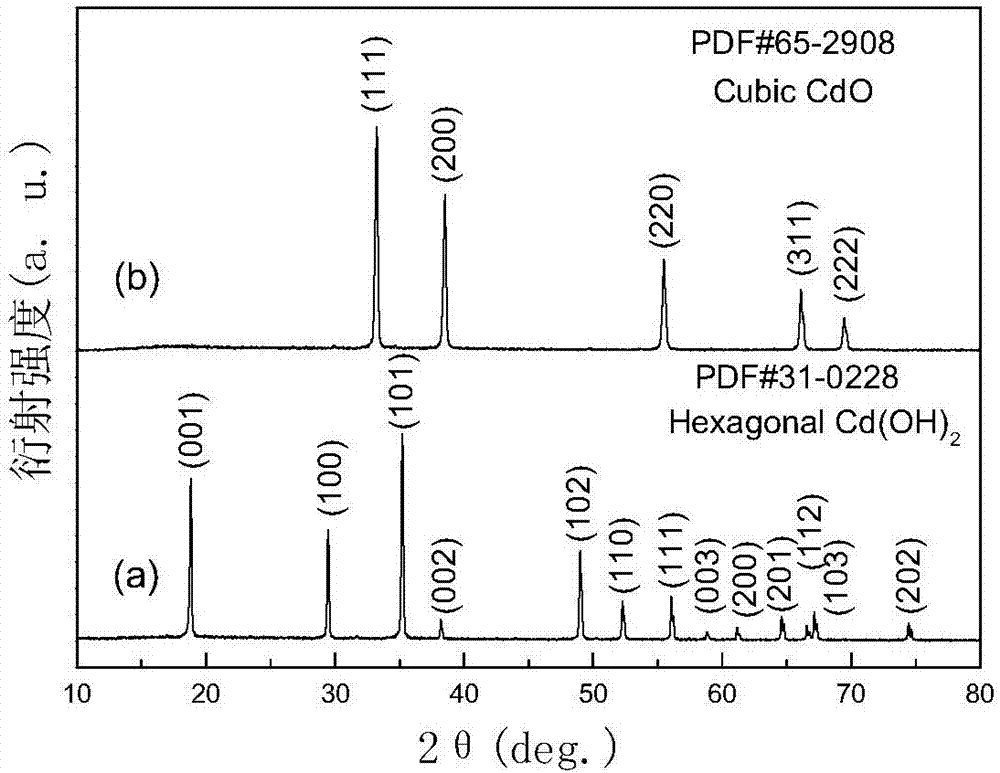

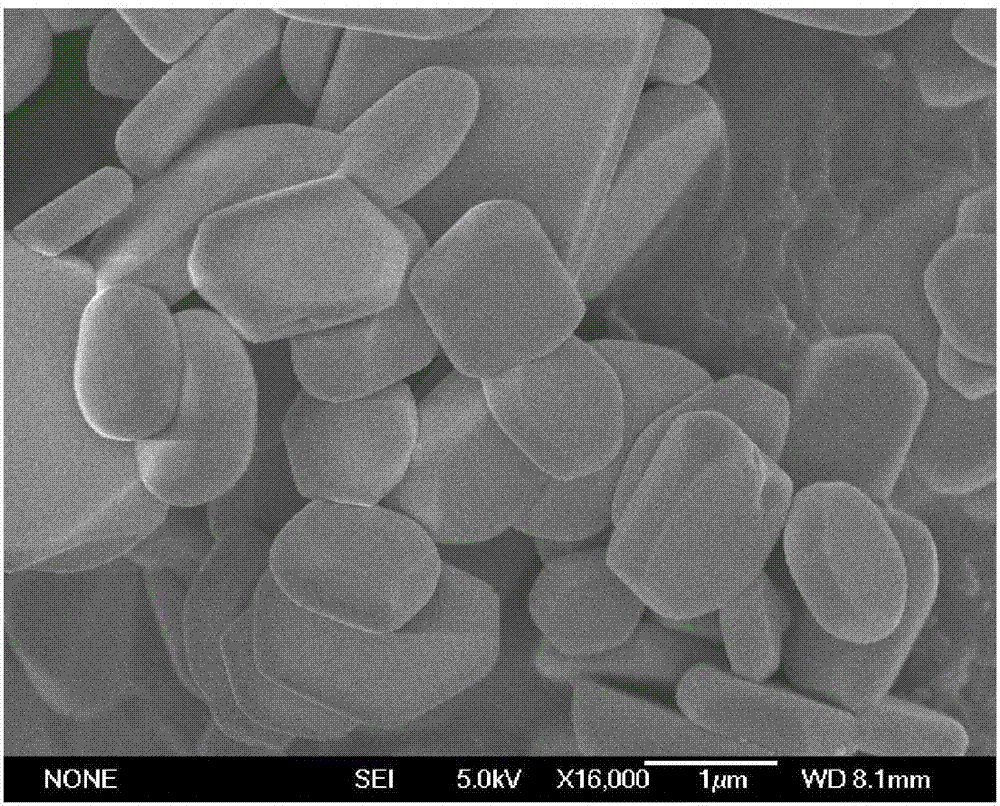

[0044] (2) Put the mixed solution obtained in step (1) in a reaction kettle, and react at 200° C. for 12 hours. The obtained product was washed with twice-distilled water and absolute ethanol in turn, and dried at 85°C for 30 hours to obtain a cadmium hydroxide precursor; its microscopic morphology was characterized b...

Embodiment 2

[0054] Example 2. Prepare hexagonal cadmium oxide nanodiscs as described in Example 1. The sequence of steps remains the same, and the weight of cadmium nitrate tetrahydrate remains unchanged, which is still 0.7712g cadmium nitrate tetrahydrate (2.5mmol). The difference is that,

[0055] In step (1), the lithium hydroxide weighed is 0.2413g (5.75mmol). The molar ratio of cadmium nitrate to lithium hydroxide = 1:2.3; after the lithium hydroxide solution was added dropwise to the cadmium nitrate ethanol solution, the stirring time was continued for 50 minutes.

[0056] In step (2), the product drying condition is 80° C. for 36 hours.

[0057] In step (3), the calcination condition of the cadmium hydroxide precursor is: calcination at 180° C. for 1 hour, and then calcination at 320° C. for 2 hours.

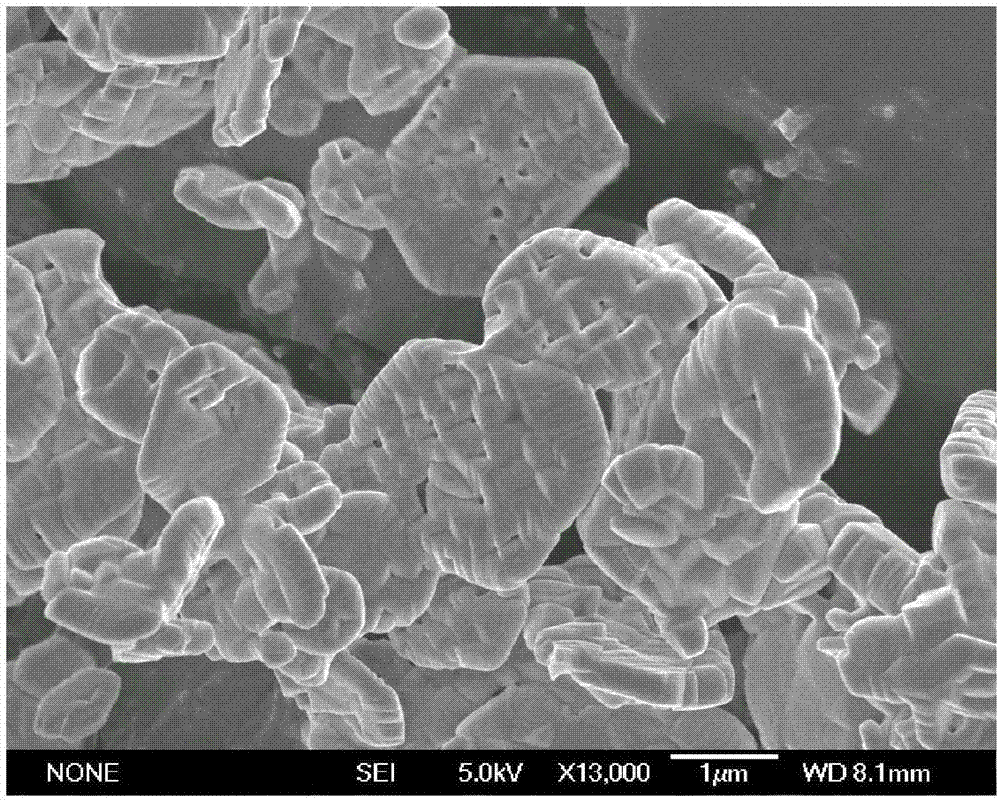

[0058] The prepared hexagonal cadmium oxide nanodisks. The side length of the small cube is 230-260nm, the side length of the nano-disk is 500-750nm, and the thickness is 230-250n...

Embodiment 3

[0060] Embodiment 3, prepare hexagonal cadmium oxide nano-disk as described in embodiment 1, step sequence is unchanged, the quality of the cadmium nitrate tetrahydrate that weighs is constant, difference is:

[0061] In step (1), the lithium hydroxide weighed is 0.2832g (6.75mmol); the molar ratio of cadmium nitrate to lithium hydroxide=1:2.7. Lithium hydroxide solution was added dropwise to the cadmium nitrate ethanol solution, and the stirring was continued for 70 min.

[0062] In step (2), the product drying condition is 90° C. for 24 hours.

[0063] In step (3), the calcination condition of the cadmium hydroxide precursor is: calcination at 220° C. for 70 minutes, and then 100 minutes at 320° C. The prepared hexagonal cadmium oxide nanodisks. The side length of the small cube is 240-260nm, the side length of the nano-disk is 800-900nm, and the thickness is 250-270nm. The morphology of the hexagonal cadmium oxide nanodisks is complete.

[0064] Carry out catalytic prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com