Planar fluorescent condenser

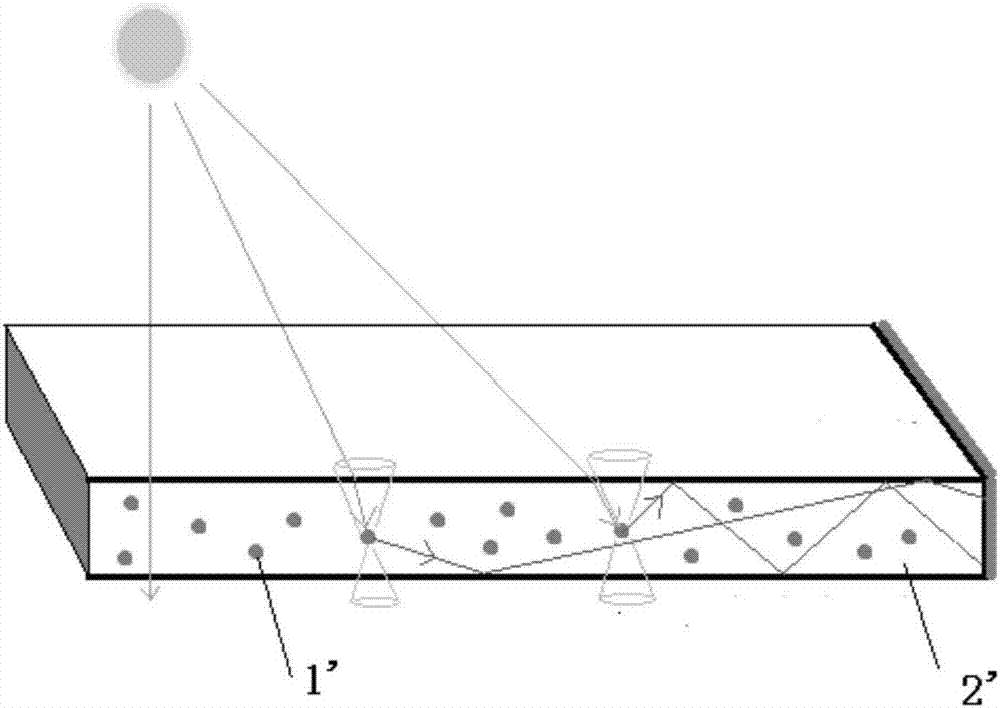

A light concentrator and planar optical waveguide technology, applied in the field of light concentrators, can solve the problems of limiting the wide application of carbon quantum dots, low photoelectric conversion efficiency, and complicated preparation process, so as to improve the photoelectric conversion efficiency, avoid direct exposure to sunlight, and light The effect of high absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

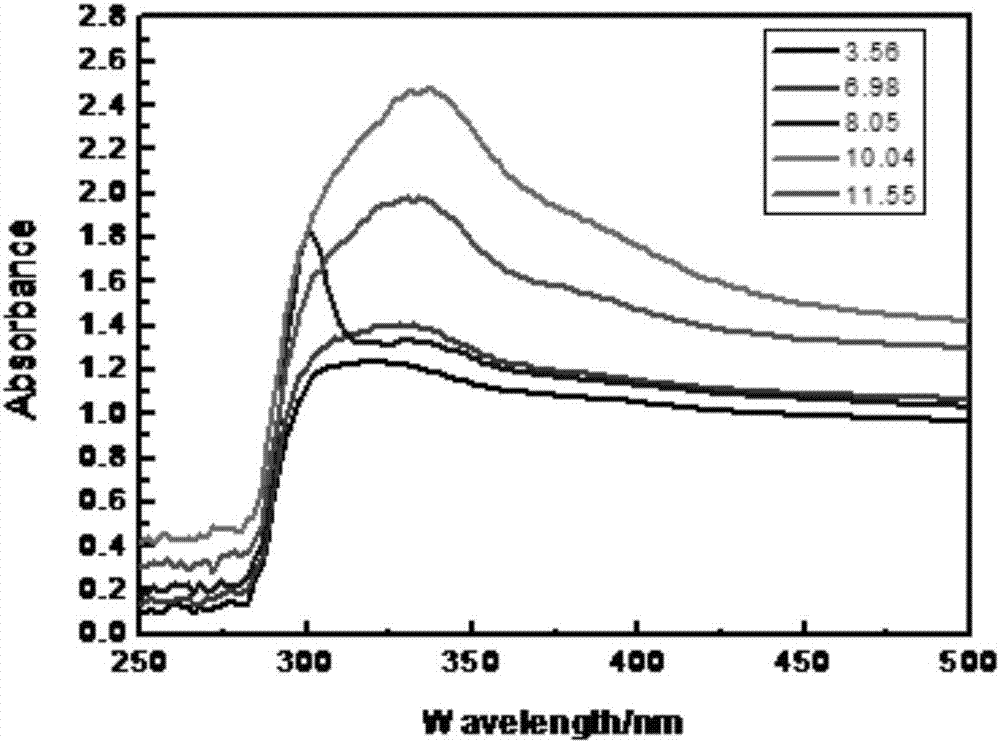

Examples

Embodiment Construction

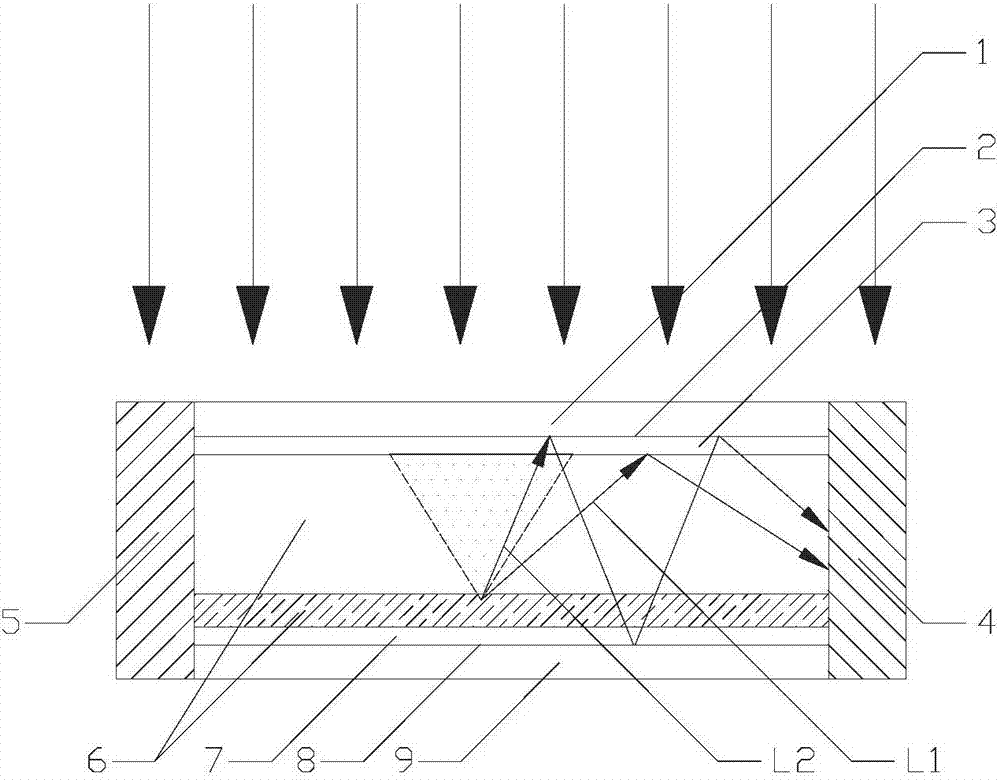

[0045] Such as figure 2 As shown, a flat fluorescent concentrator according to the present invention includes solar cells 4 and 5 placed on both sides, and a glass cover plate 1 and a selective reflection layer placed in the middle from top to bottom. 2. The upper air thin layer 3, the fluorescent planar optical waveguide layer 6, the lower air thin layer 7 and the high reflection film 8, wherein the fluorescent planar optical waveguide layer 6 includes a fluorescent substance and a planar optical waveguide, and the fluorescent substance is placed in the planar optical waveguide In the surface or planar optical waveguide, the fluorescent substance is a carbon quantum dot material, the outer layer of the fluorescent substance is wrapped with a ZnS reflective film, and the planar optical waveguide is a high molecular polymer, specifically: the high molecular polymer It is polymethyl methacrylate, polycarbonate, polydimethylsiloxane or polyethylene.

[0046]The glass cover plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com