A method for adsorbing and separating pentamethylenediamine by using ultra-high cross-linked resin

An ultra-high cross-linked resin, adsorption and separation technology, applied in the biological field, can solve the problems of difficult downstream separation, achieve large adsorption capacity, avoid environmental pollution problems, and have long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

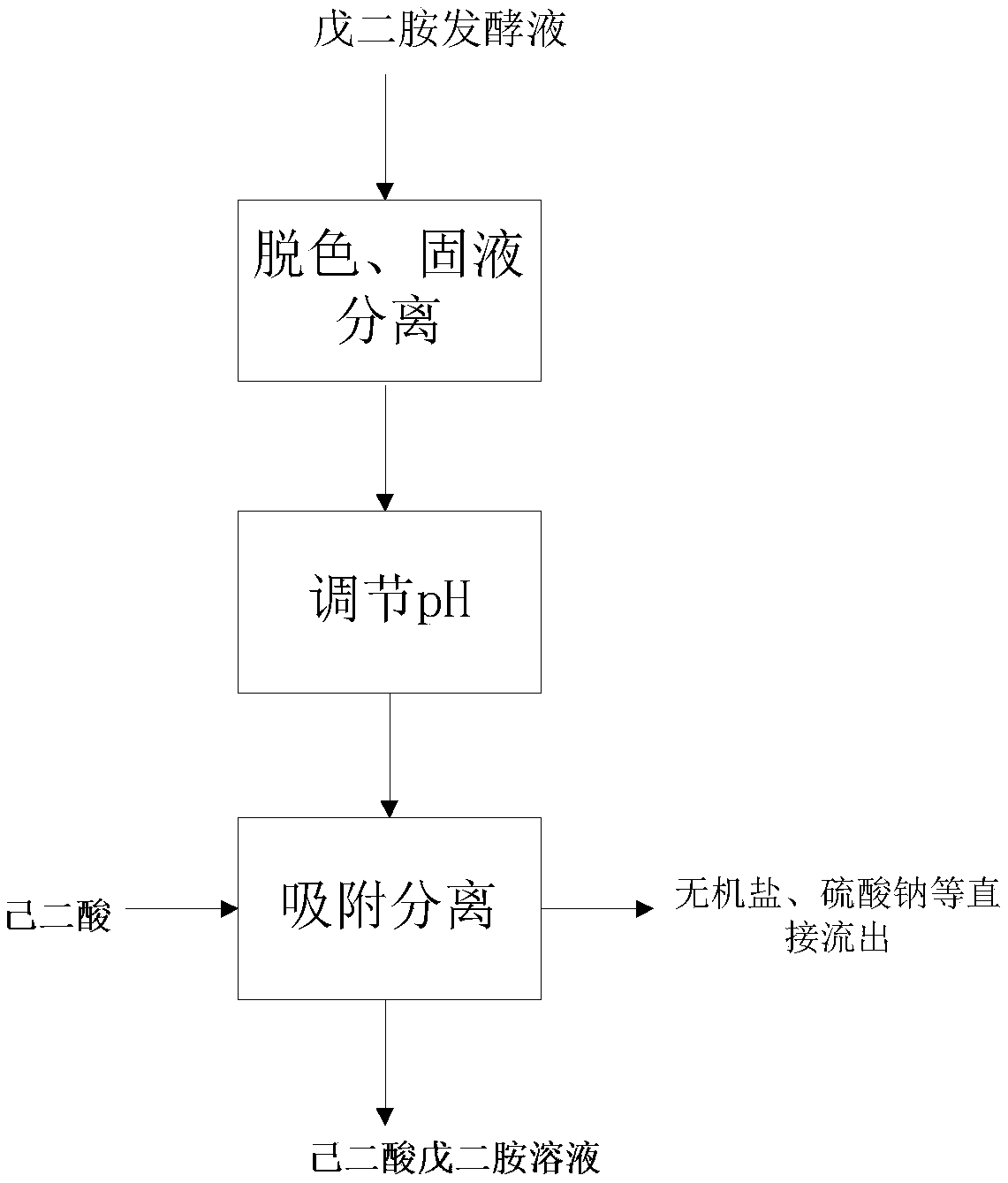

[0042] Preparation and pretreatment of pentamethylenediamine fermentation broth

[0043] The source of the aqueous solution of the crude product of pentamethylenediamine is not particularly limited, and it can be any fermentation broth containing pentamethylenediamine prepared by any biological method, for example, the pentamethylenediamine obtained after lysine or lysine salt is catalyzed by lysine decarboxylase Crude conversion solution. The transformation solution was centrifuged to remove the bacteria, and the supernatant was added with 1.5% (g / L) activated carbon and stirred at 20°C for 1 hour to decolorize, then centrifuged at 6000-8000rpm for 5-10 minutes, and then filtered to remove the activated carbon , and then add enough NaOH to free pentamethylenediamine, and adjust the pH to 12.5-13.5.

[0044] The content of pentamethylenediamine in the pentamethylenediamine fermentation broth after the above pretreatment is about 70g / L.

Embodiment 2

[0046] Preparation and pretreatment of ultra-high cross-linked resin HD-6

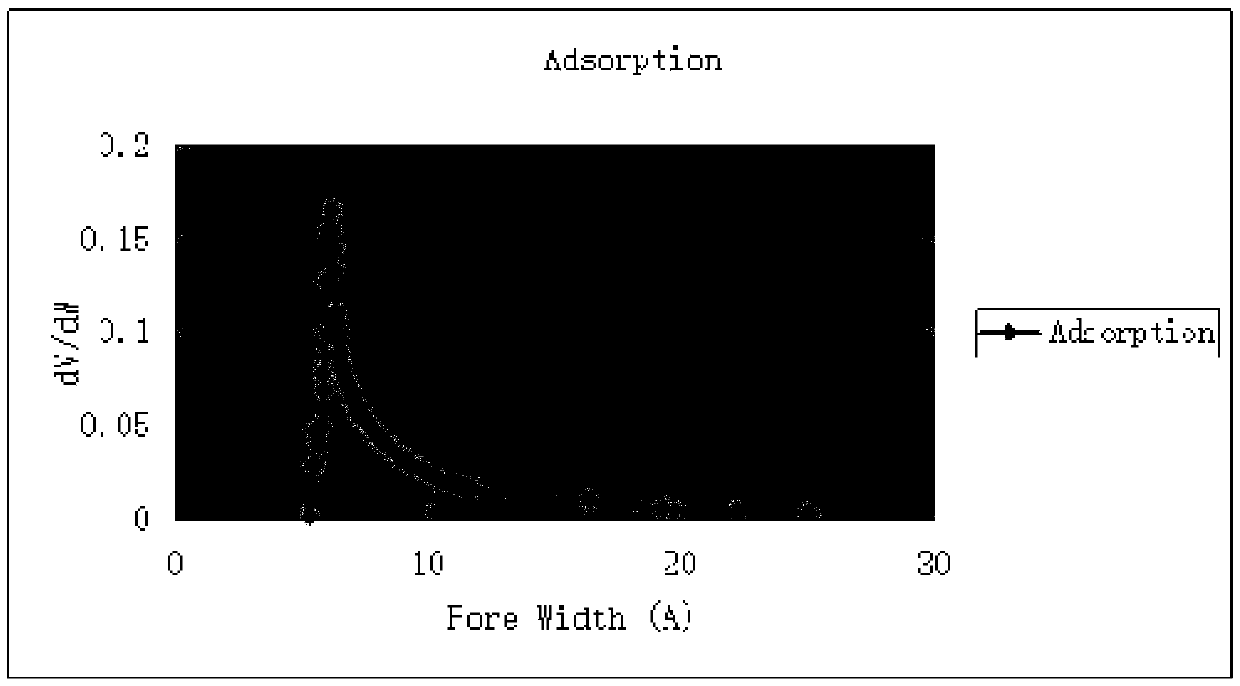

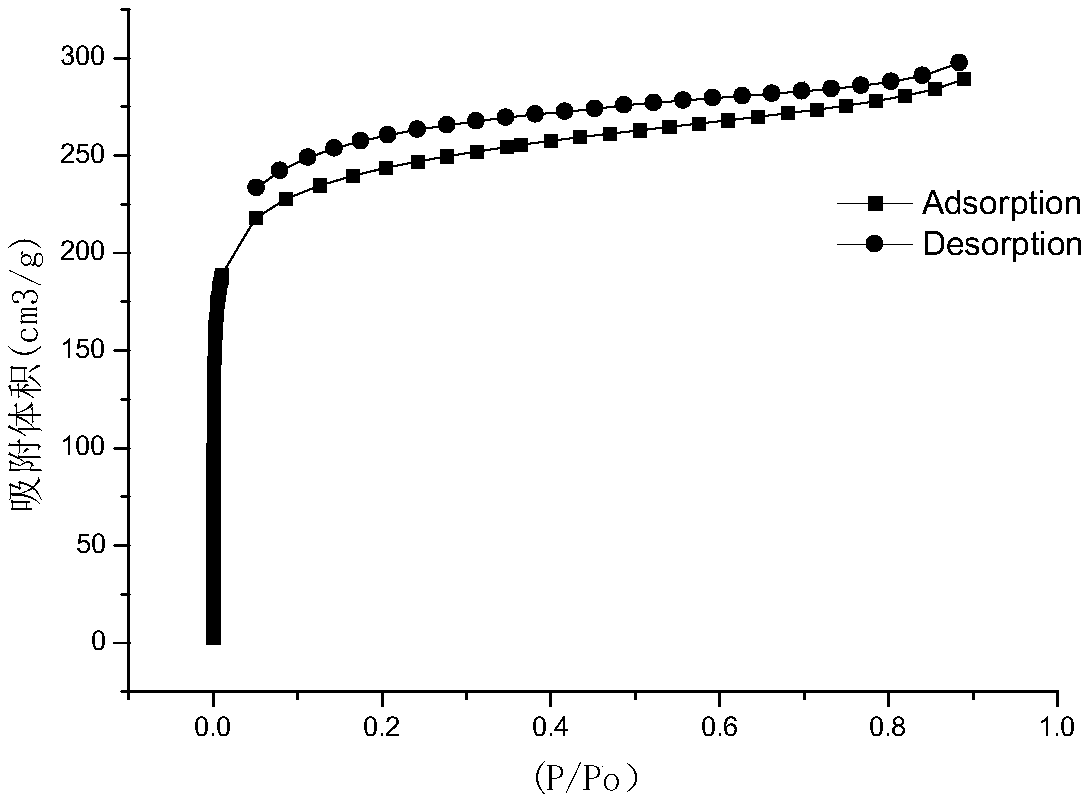

[0047]The preparation method of the ultra-high cross-linked resin can be found in the patent CN105884956A, that is, polystyrene-divinylbenzene is used as the skeleton, and it is obtained through the Friedel-Crafts cross-linking reaction. The ultra-high cross-linked resin has weak polarity and hydrophilicity Good; the average particle size is 0.5-0.8mm, the water content is 43wt%, the average pore size is 4.94nm, the porosity is 30%-40%, and the wet density is 1.09g / cm 3 , with an average specific surface area of 806m 2 / g, average pore volume 0.995cm 3 / g, the functional group is carbonyl, named HD-6.

[0048] figure 2 To prepare the pore size distribution figure of the resulting ultra-high cross-linked resin HD-6; image 3 To prepare the BET figure of the super high cross-linked resin HD-6.

[0049] Pretreatment of ultra-high cross-linked resin HD-6: wash the resin with 2BV 1mol / L HCL solution...

Embodiment 3

[0051] Fixed bed resin column separation

[0052] The pentamethylenediamine fermentation broth after the pretreatment of Example 1 is passed through the adsorption column equipped with the ultra-high cross-linked resin after the pretreatment of Example 2 from top to bottom at a flow rate of 4BV / h, using fixed bed adsorption, and the resin column The aspect ratio is 15, pentamethylenediamine is selectively adsorbed, stop feeding when the feed volume reaches 4BV, and drain the liquid in the column; wash impurities with deionized water at a flow rate of 2BV / h until the effluent No inorganic salts, residual sugar and other impurities, then drain the deionized water; add 0.5mol / L adipic acid aqueous solution to the top of the adsorption column at a flow rate of 0.5BV / h, after desorption, there is basically no glutaric acid in the effluent Amines, desorption is complete. Desorption curve see Figure 4 . Then, deionized water is fed at a flow rate of 1BV / h to clean the adipic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com