Solid catalyst for synthesizing butadiene from alcohol, and preparation and application thereof

A solid catalyst, butadiene technology, applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc., can solve the problems affecting the selectivity and life of butadiene, butadiene Low selectivity, short life, etc., to achieve the effects of sustainable energy development, easy scale-up, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

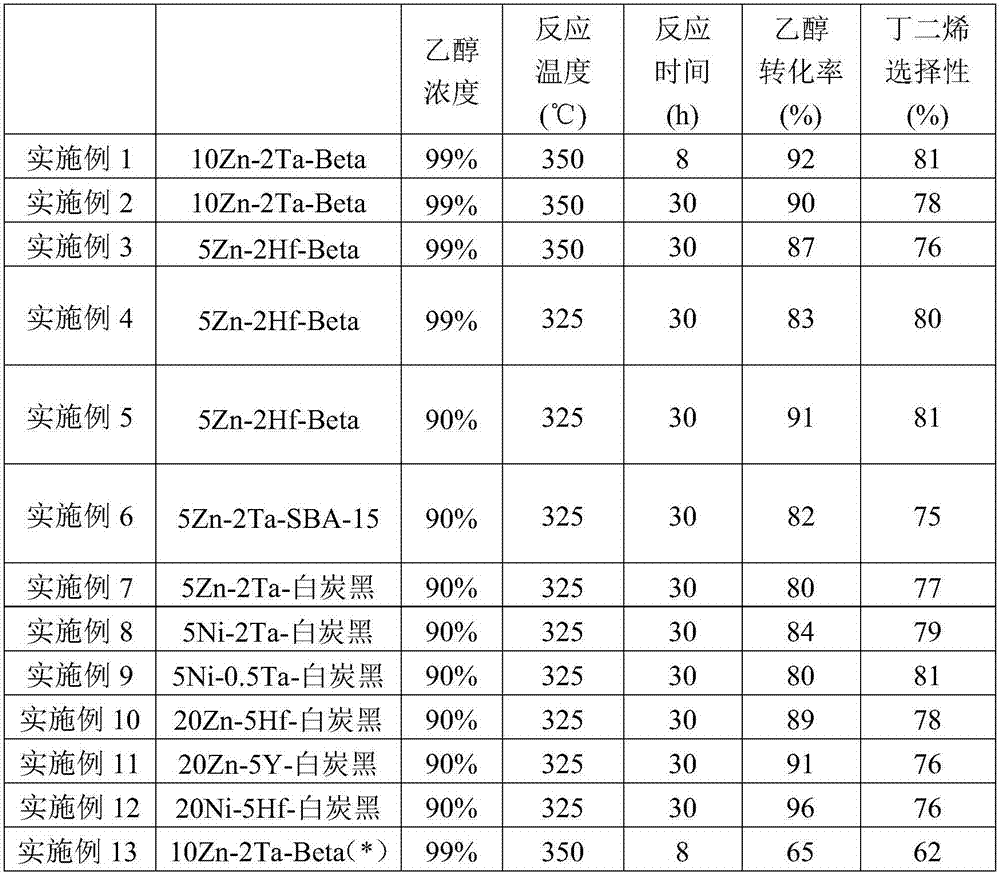

Embodiment 1

[0050] 1. Preparation of solid catalyst

[0051] (1) Take 2.1g Zn(NO 3 ) 2 ·6H 2 O and 1g Na 2 SiO 3 9H 2 O, were dissolved in 100mL deionized water. Under stirring conditions, the Zn(NO 3 ) 2 The aqueous solution was added dropwise to Na 2 SiO 3 In the solution, heat up to 100°C, stir for 12 hours, dry the obtained white powder at 110°C overnight, and then roast at 500°C for 4 hours to obtain a zinc silicate active component with a Zn / Si molar ratio of 2.3:1 ;

[0052] (2) Add 5 g of Beta molecular sieve into 100 mL of isobutanol dissolved with 0.224 g of tantalum ethoxide, heat and stir until the solvent evaporates to dryness, and dry the obtained white powder at 160°C for 8 hours to prepare a Ta with a tantalum loading of 2wt%. - Beta active ingredient;

[0053] (3) Add the zinc silicate obtained in step (1) and the Ta-Beta active component obtained in step (2) into 100 mL of deionized water, stir at 35 °C for 2 h, and dry the obtained powder sample at 110 °C A...

Embodiment 2

[0057] The difference between embodiment 2 and embodiment 1 is that the catalytic reaction time is 30h, and all the other reaction conditions are the same as embodiment 1. The specific experimental results are shown in Table 1.

Embodiment 3

[0059] The difference between Example 3 and Example 2 is that the catalyst 5wt%Zn-2wt%Hf-Beta is prepared, abbreviated as 5Zn-2Hf-Beta, and the rest of the reaction conditions are the same as in Example 2. The specific experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com