Method for extracting thuja essential oil by fermentation with microbial system

A technology for thuja essential oil and microorganisms is applied in the extraction of thuja essential oil, and the field of thuja essential oil is extracted by fermentation with a microbial system, so as to achieve the effects of simple process, improved extraction rate and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

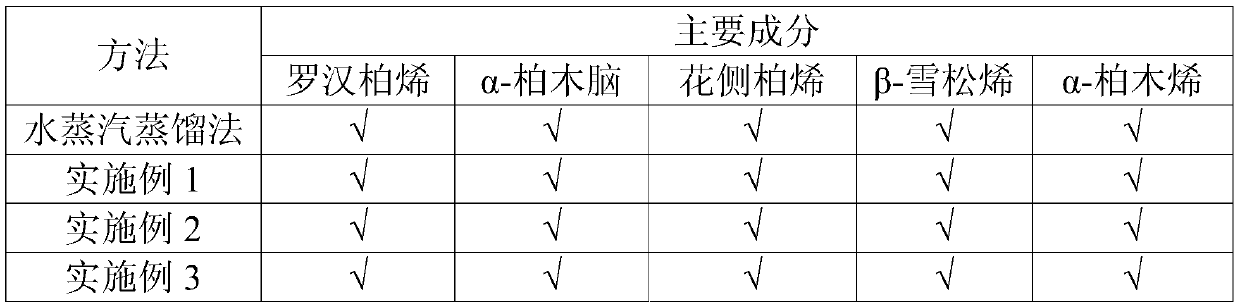

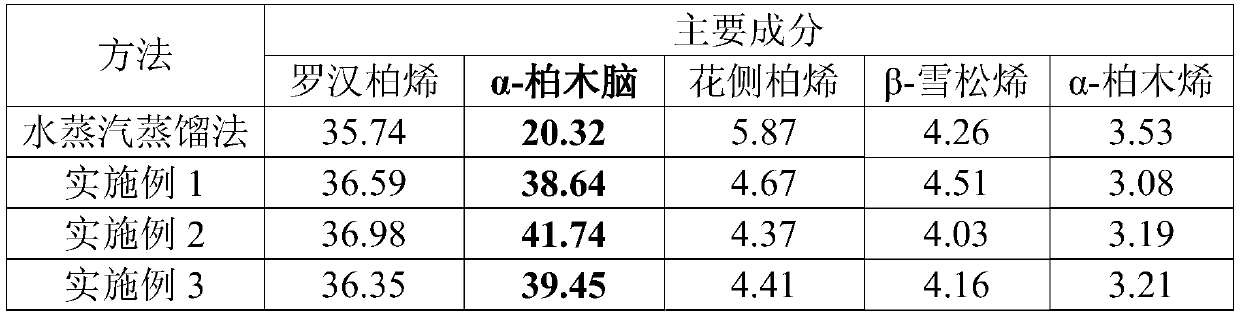

Embodiment 1

[0019] Get 10kg of thuja raw material, crush it into sawdust; adjust the moisture content to 40%, add 2% sucrose, 0.5% yeast extract, 0.5% Trichoderma viride spore powder (200 million / g), mix well and place in a solid reactor Fermentation at 25-30°C with intermittent aeration and stirring for 7-15 days, the aeration rate is 0.07-0.1vvm, 1-3 minutes each time, to promote the disintegration of thuja raw material cellulose or lignin structure; then fermented The Thuja raw material was placed in a steam distillation extractor for distillation and extraction for 7 hours, the oil yield was 1.13kg, and the essential oil yield was 11.3%.

Embodiment 2

[0021] Get 10kg of thuja raw material, crush it into sawdust; adjust the moisture content to 50%, add 2% sucrose, 0.5% yeast extract, 5% Trichoderma viride spore powder (2 billion / g), mix well and place in a solid reactor Fermentation at 25-30°C with intermittent aeration and stirring for 7-15 days, the aeration rate is 0.07-0.1vvm, 1-3 minutes each time, to promote the disintegration of thuja raw material cellulose or lignin structure; then fermented The Thuja raw material was placed in a steam distillation extractor for distillation and extraction for 7 hours, the oil yield was 1.511kg, and the essential oil yield was 15.1%.

Embodiment 3

[0023] Get 10kg of thuja raw material, crush it into sawdust; adjust the moisture content to 45%, add 2% sucrose, 0.5% yeast extract, 2.5% Trichoderma korningii spore powder (200 million / g) and 2.5% Trichoderma viride spore powder (1,000,000,000 / g), mixed evenly, placed in a solid reactor, and fermented at 25-30°C with intermittent aeration for 7-15 days, with an aeration rate of 0.07-0.1vvm, 1-3 minutes each time, to promote The cellulose or lignin structure of the cypress raw material was disintegrated; then the fermented thuja raw material was distilled and extracted for 7 hours in a steam distillation extractor, and the oil yield was 1.31kg, and the yield of essential oil was 13.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com