Strontium titanate/titanium dioxide composite nano fibers and preparation method thereof

A technology of composite nanofibers and titanium dioxide, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, spinning solution preparation, etc., can solve problems such as not being able to meet the requirements of photocatalytic activity, and achieve sunlight Improved utilization rate, long life, and improved photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A method for preparing strontium titanate / titanium dioxide composite nanofibers, comprising the following steps:

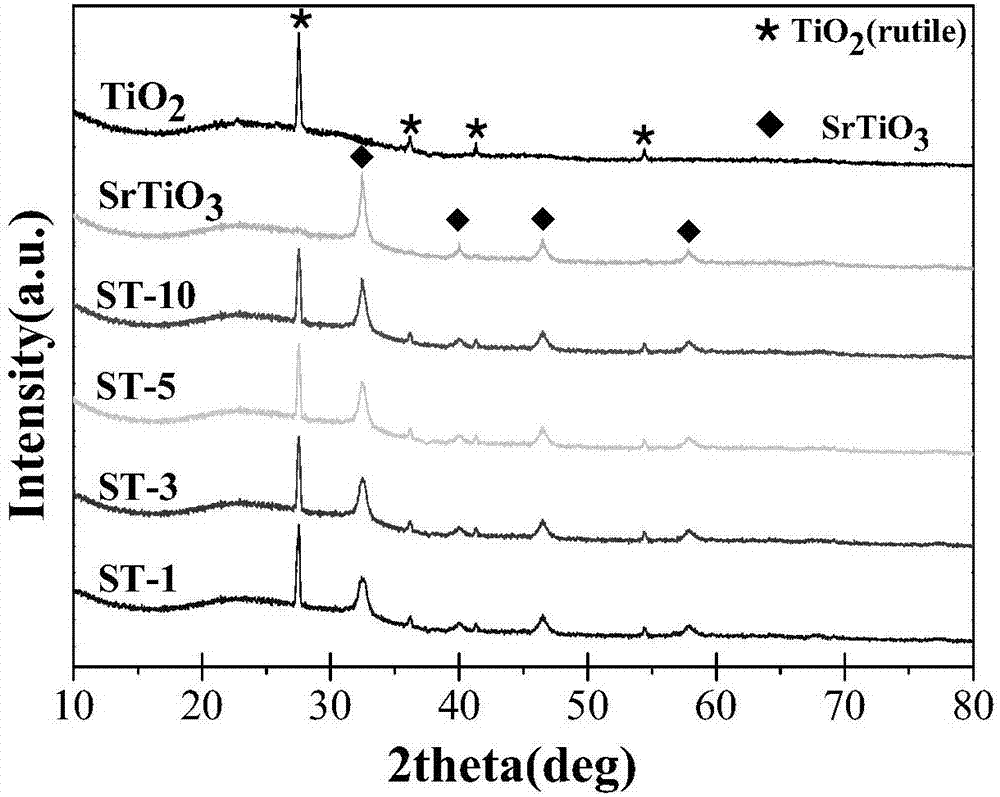

[0017] (1) Disperse 2.2g of polyvinylpyrrolidone (PVP) into a mixed solution composed of 8ml of N,N-dimethylformamide (DMF) and 2ml of glacial acetic acid. After the dispersion is uniform, a uniform and stable transparent solution is obtained; add 2g After tetrabutyl titanate is uniformly dispersed, strontium acetate (5.3mg-ST1, 15.9mg-ST3, 26.5mg-ST5, 53mg-ST10) is added to form a uniform and stable spinning solution.

[0018] (2) Spinning with the spinning solution prepared in step 1, and receiving it through an aluminum foil drum receiver to obtain a fiber precursor; wherein, the diameter of the nozzle is 0.5mm, and the flow rate is 0.6ml / h. The spinning voltage is 15kV, the distance between the needle and the grounded aluminum foil roller receiver is 15cm, and the ambient humidity during the electrospinning process is below 40%;

[0019] (3) The fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com