Paper sheet surface sizing starch glue and processing method thereof

A technology of surface sizing and processing method, applied in the field of starch glue, can solve the problems of crystallization of starch glue particle solution and poor storage viscosity stability, and achieve the effects of being beneficial to the reuse of white water, improving the binding force and reducing the number of broken ends.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

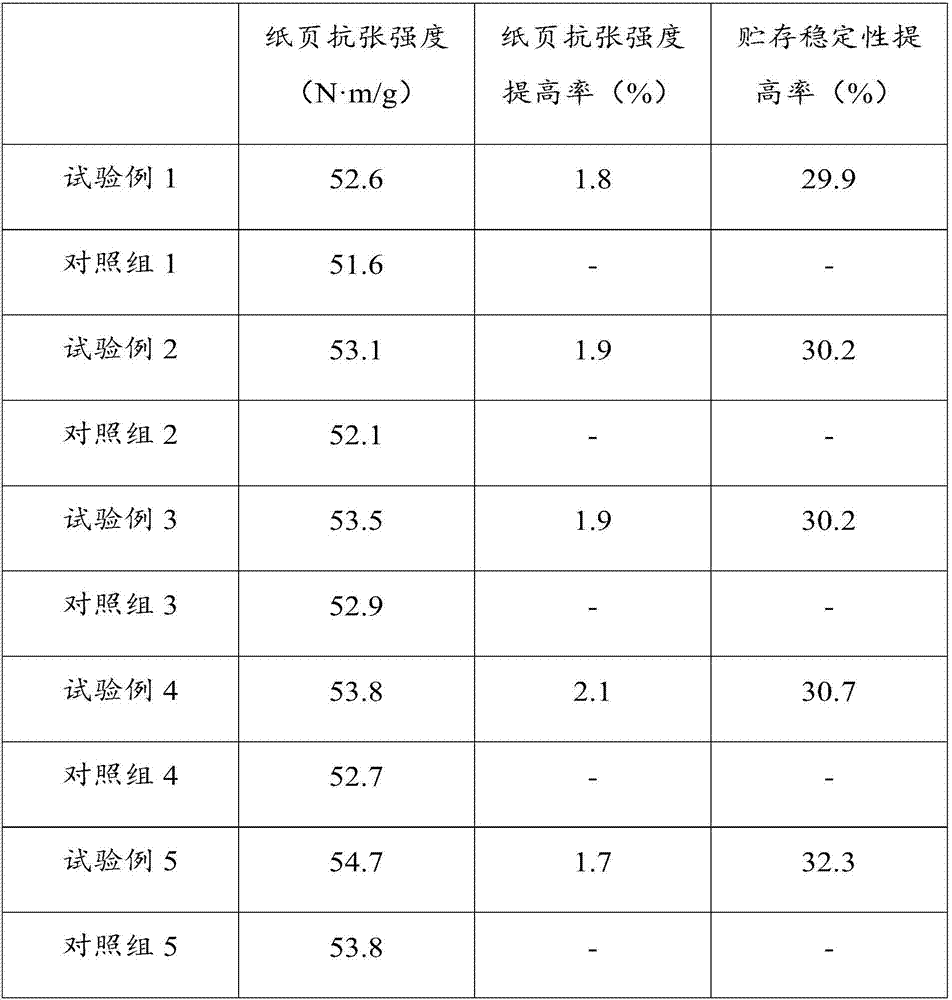

Examples

Embodiment 1

[0029] Water and starch are added into the glue boiling pot and mixed to obtain a starch liquid, wherein the mass percentage of the starch in the starch liquid is 25%. Then, a starch complex enzyme containing α-amylase, β-amylase, glycerol and salt in a weight ratio of 50:5:10:2 was added to the above-mentioned starch liquid, and heated at 65° C. for 20 minutes to obtain a starch gel. Taste. Among them, the weight ratio of starch compound enzyme to starch is 0.01:100, the enzyme activity of α-amylase is 3000U / mL, and the enzyme activity of β-amylase is 900U / mL.

[0030] Then, under the condition of 95° C., the primary product of starch glue was subjected to an enzyme-inactivating treatment for 15 minutes. Next, add a starch glue reinforcing agent with a weight ratio of 100:0.5 to the starch glue product after deactivating the enzyme, adjust the pH of the glue solution after mixing, and obtain a paper surface sizing with a pH of 8.0 and a viscosity of 10 MPa·s. starch glue. ...

Embodiment 2

[0032] Water and starch are added into the glue boiling pot according to the order of water first and then starch, and mixed to obtain starch liquid, wherein the mass percentage of starch in the starch liquid is 30%. Then, a starch complex enzyme containing α-amylase, β-amylase, glycerol and salt in a weight ratio of 65:10:20:5 was added to the above starch liquid, and heated at 75°C for 15 minutes to obtain a starch gel. Taste. Among them, the weight ratio of starch compound enzyme to starch is 0.03:100, the enzyme activity of α-amylase is 4000U / mL, and the enzyme activity of β-amylase is 1000U / mL.

[0033] Then, under the condition of 100°C, the primary product of starch glue was subjected to an enzyme-inactivating treatment for 12 minutes. Next, add a starch glue reinforcing agent with a weight ratio of 100:1 to the starch glue product after deactivation, adjust the pH of the glue solution after mixing and dilute with water to obtain a paper surface with a pH of 8.5 and a ...

Embodiment 3

[0035] Water and starch are added into the glue boiling pot according to the order of water first and then starch, and mixed to obtain starch liquid, wherein the mass percentage of starch in the starch liquid is 28%. Then add starch complex enzyme containing α-amylase, β-amylase, glycerol and salt in the weight ratio of 57.5:8:15:3.5 to the above starch liquid, and heat at 70°C for 18min to obtain starch gel Taste. Among them, the weight ratio of starch compound enzyme to starch is 0.02:100, the enzyme activity of α-amylase is 3500U / mL, and the enzyme activity of β-amylase is 950U / mL.

[0036] Then, under the condition of 98° C., the primary product of starch glue was treated with enzyme inactivation for 10 minutes. Next, add a starch glue reinforcing agent with a weight ratio of 100:0.8 to the starch glue product after the enzyme is deactivated, adjust the pH of the glue solution after mixing, and dilute with water to obtain a paper sheet with a pH of 7.5 and a viscosity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com