Electrode with self-support structure, and preparation method thereof, and application thereof

A self-supporting structure and electrode technology, applied to battery electrodes, structural parts, hybrid capacitor electrodes, etc., can solve the problems of high price and severe toxicity, improve utilization rate, save pressing process, and increase active surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

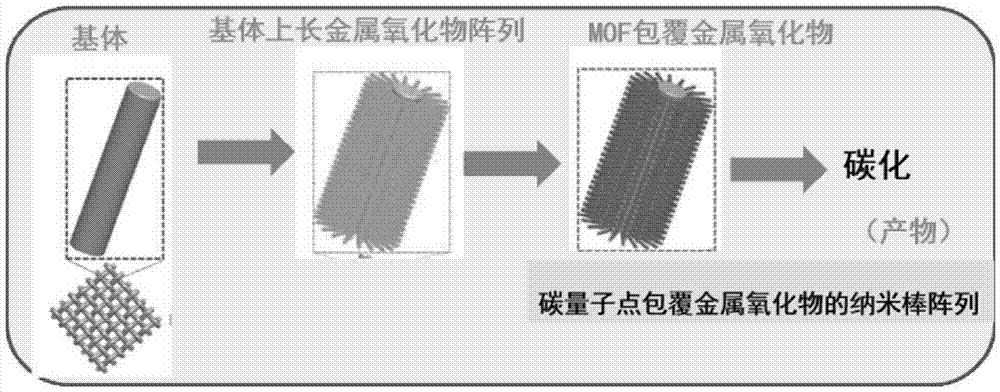

Method used

Image

Examples

Embodiment 1

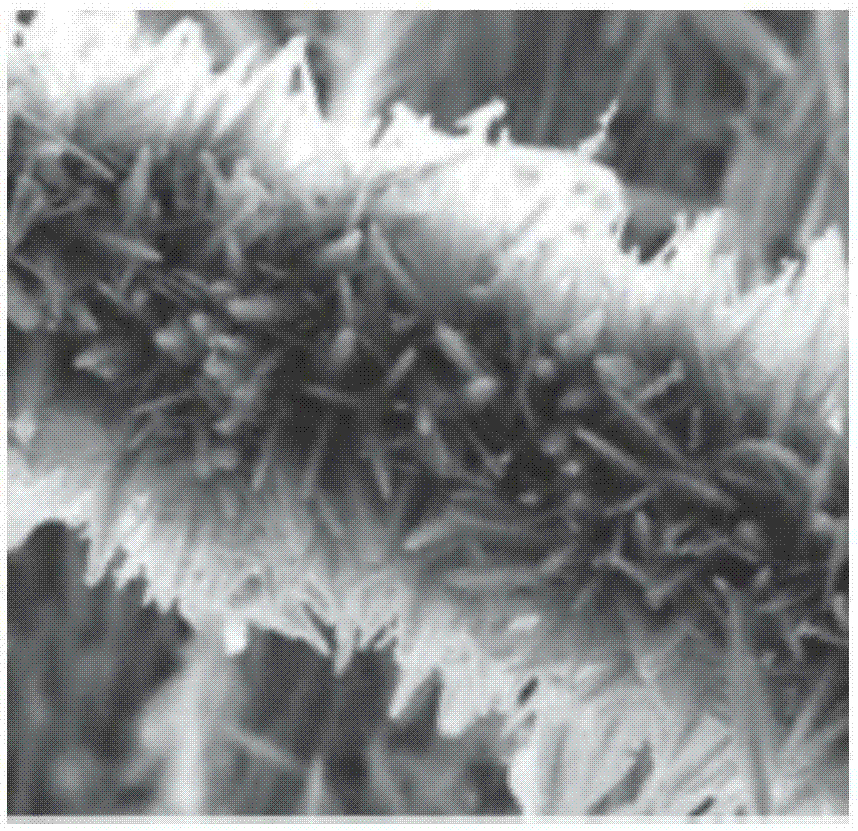

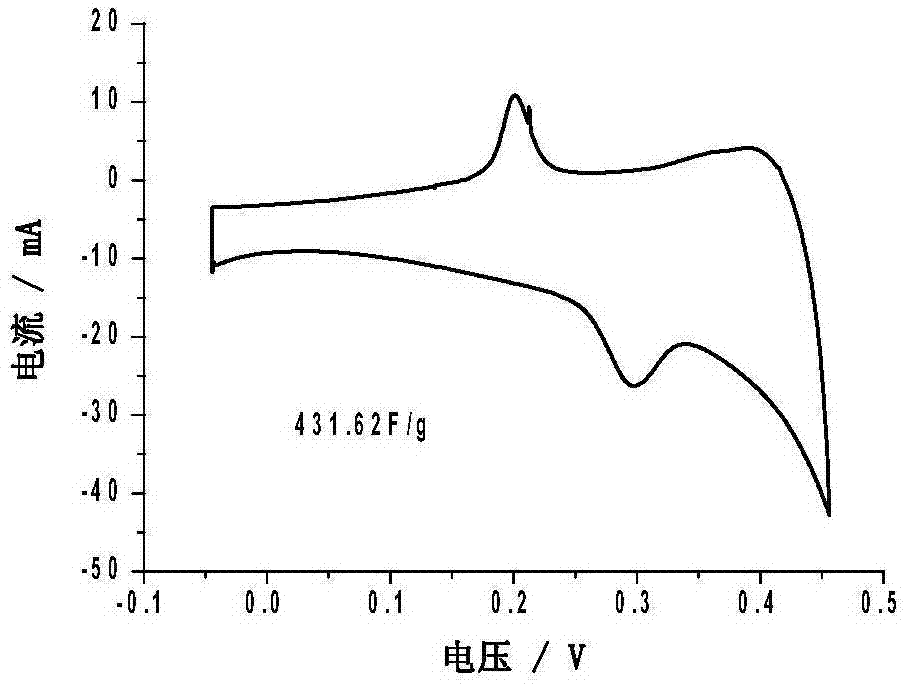

[0030] Mix nickel nitrate and hexamethylenetetramine in water at a molar ratio of 1:1, add 28% ammonia water to adjust the pH value to 8, stir for 0.5h, and then transfer to a hydrothermal reaction kettle to form solution A; The mass concentration of solid matter in solution A is 10%, put 4×4cm carbon cloth (thickness is 1mm, porosity 10%) into solution A at 45°, and react at 80°C for 12h to obtain B; After cleaning with acetone, add it to the solution C containing dimethylimidazole (C is a mixture of N-N dimethylformamide and water, the ratio is (1:1)); the amount of C added is suitable for submerging the current collector , 100°C for 12h, washed with water and ethanol to obtain C; C was calcined at 500°C for 5h under Ar conditions to obtain the target product D. Cut the obtained product into small discs with a diameter of 14mm, weigh them, and dry them in vacuum at 60°C for 24 hours. Use the small discs as the working electrode, platinum as the counter electrode, saturated c...

Embodiment 2

[0033] Take cobalt nitrate and hexamethylenetetramine at a molar ratio of 1:1 and mix them evenly in ethanol, then add 28% ammonia water to adjust the pH value to 10, stir for 5 hours and then transfer to a hydrothermal reaction kettle to form solution A; The concentration of solid matter in solution A is 50%. Put 4×4cm nickel foam vertically into solution A with a thickness of 1mm and a porosity of 90%. React at 100°C for 24 hours to obtain B; clean B with acetone and add Add to solution C containing dimethylimidazole, (C is a mixture of N-N dimethylformamide and water, the ratio is (4:1)); the amount of C added is suitable for submerging the current collector, and the temperature is kept at 50°C for 12h , washed with water and ethanol to obtain C; C was calcined at 1000°C for 2h under Ar conditions to obtain the target product D. Cut the obtained product into small discs with a diameter of 14mm, weigh them, and dry them in vacuum at 60°C for 24 hours. Use the small discs as ...

Embodiment 3

[0036]Mix potassium permanganate and hexamethylenetetramine in water at a molar ratio of 1:1, add 0.5M sodium hydroxide to adjust the pH to 9, stir for 5 hours, and then transfer to a hydrothermal reaction kettle to form a solution A; the concentration of solid matter in solution A is 50%. Put 4×4cm carbon paper vertically into solution A with a thickness of 10 μm and a porosity of 60%. React at 90°C for 24 hours to obtain B; wash B with acetone After cleaning, add it to the solution C containing dimethylimidazole (C is a mixture of N-N dimethylformamide and water, the ratio is (3:1)); the amount of C added is suitable for submerging the current collector, 70 ℃ for 12h, washed with water and ethanol to obtain C; C was calcined at 900℃ for 3h under Ar condition to obtain the target product D. Cut the obtained product into small discs with a diameter of 14mm, weigh them, and dry them in vacuum at 60°C for 24 hours. Use the small discs as the working electrode, platinum as the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com