LTCC substrate component and eutectic sintering process method thereof

A process method and substrate technology, applied in the field of brazing process in microelectronic assembly, can solve the problems of large microwave loss, large resistivity of conductive adhesive bonding, small size of hair buttons, etc., achieve good welding, achieve high-precision control, The effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A specific implementation process of a eutectic sintering process for an LTCC substrate assembly is as follows:

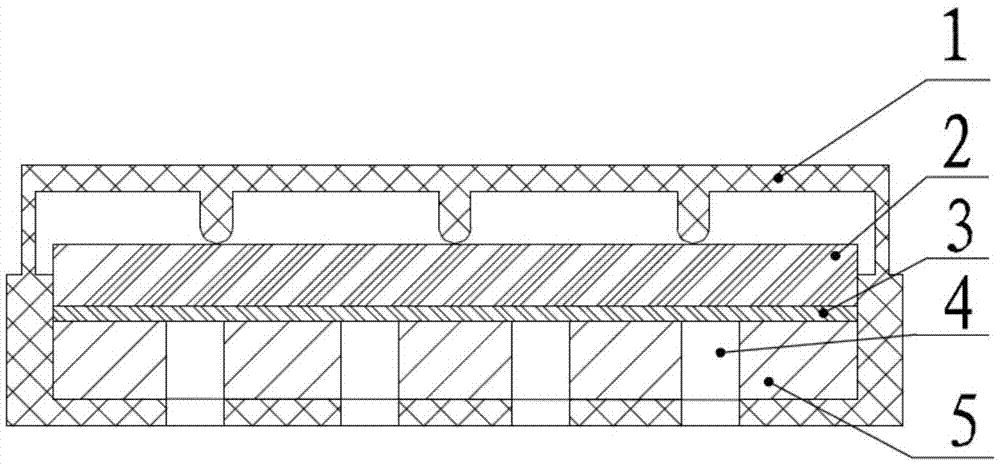

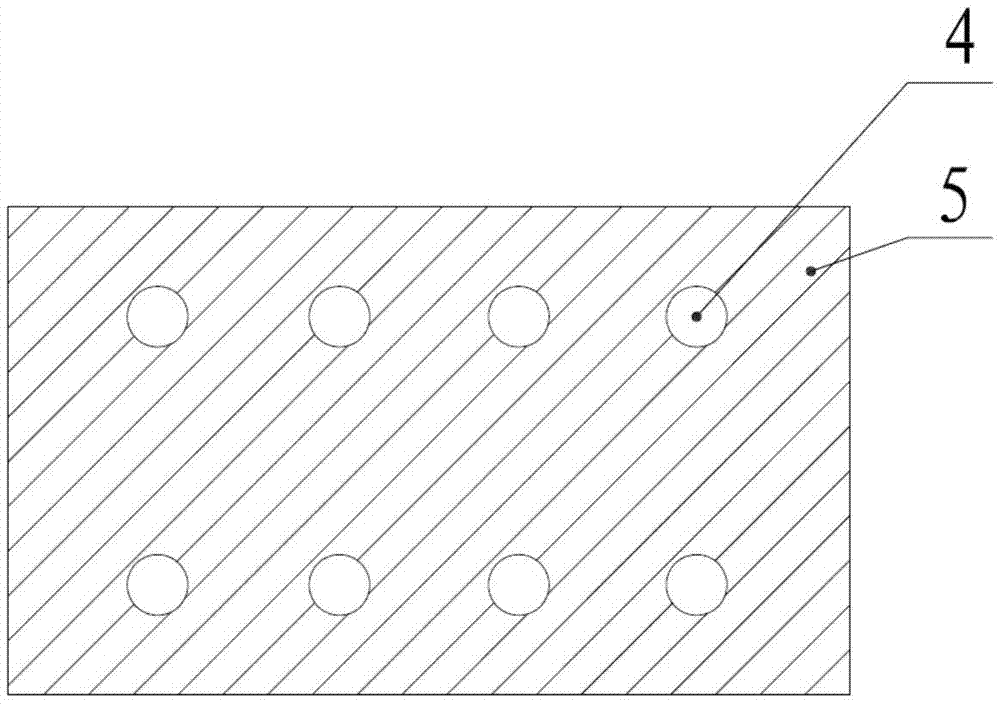

[0034] Step 1: If figure 1 , 2 As shown, according to the structural drawing of the LTCC substrate structural part 5 that requires eutectic sintering, processing can provide 0.02g / mm2 fixed pressure, 0.1mm positioning accuracy for eutectic sintered products of different thicknesses, and elastic positioning tooling that can conduct heat well at the same time , the elastic positioning tooling 1 needs to reserve a high temperature protective solder resist coating position at the installation hole position of the connector on the LTCC substrate structure 5;

[0035] Step 2: Process a preformed silver-tin solder sheet with a thickness of 0.08 mm that matches the pressure applied by the elastic positioning tool 1 according to the same size as the LTCC substrate structural part 5;

[0036] Step 3: Ultrasonic cleaning the elastic positioning tool 1 described in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com