Large power thick film circuit high temperature sintering resistor paste for aluminium nitride base materials, and preparation method thereof

A thick film circuit, resistance paste technology, applied in ohmic resistance heating, heating element materials, electric heating devices, etc., can solve the loss of adhesion of electronic paste, poor wettability, affecting the stability of thick film circuit components, etc. problem, to achieve the effects of good wettability, lower sintering temperature and thermal expansion coefficient, and dense adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

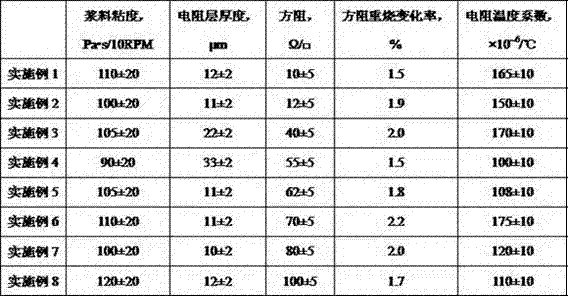

Examples

Embodiment 1

[0035] Example 1, a high-power thick-film circuit high-temperature sintering resistor paste for aluminum nitride substrates, in weight percent, includes the following components:

[0036] Inorganic binder phase 10%

[0037] Composite functional phase 70%

[0038] Organic vehicle 20%.

[0039] Wherein, for the inorganic bonding phase, by weight percentage, it includes the following components:

[0040] SiO 2 40%

[0041] B 2 o 3 20%

[0042] ZnO 10%

[0043] Al 2 o 3 10%

[0044] MgO 15%

[0045] TiO 2 2.5%

[0046] Y 2 o 3 2.5%.

[0047] For the composite functional phase, by weight percentage, it includes the following components:

[0048] Spherical silver powder 50%

[0049] Flake silver powder 49%

[0050] Nano palladium powder 1%.

[0051] For the organic vehicle, by weight percentage, it includes the following components:

[0052] Butyl Carbitol 35%

[0053] Butyl Carbitol Acetate 35%

[0054] Ethyl cellulose 25%

[0055] Polymethacrylate 2% ...

Embodiment 2

[0063] Example 2, a high-power thick-film circuit high-temperature sintering resistance paste for aluminum nitride substrates, in weight percent, includes the following components:

[0064] Inorganic binder phase 10%

[0065] Composite functional phase 70%

[0066] Organic vehicle 20%.

[0067] Wherein, for the inorganic bonding phase, by weight percentage, it includes the following components:

[0068] SiO 2 40%

[0069] B 2 o 3 25%

[0070] ZnO 15%

[0071] Al 2 o 3 10%

[0072] MgO 5%

[0073] CaF 2 2.5%

[0074] La 2 o 3 2.5%.

[0075] For the composite functional phase, by weight percentage, it includes the following components:

[0076] Spherical silver powder 50%

[0077] Flake silver powder 48%

[0078] Nano palladium powder 2%.

[0079] For the organic vehicle, by weight percentage, it includes the following components:

[0080] Ethylene glycol ether acetate 35%

[0081] Tributyl Citrate 35%

[0082] Acrylic resin 25%

[0083] Polymethacry...

Embodiment 3

[0091] Example 3, a high-power thick-film circuit high-temperature sintering resistance paste for aluminum nitride substrates, in weight percent, includes the following components:

[0092] Inorganic binder phase 15%

[0093] Composite functional phase 65%

[0094] Organic vehicle 20%.

[0095] Wherein, for the inorganic bonding phase, by weight percentage, it includes the following components:

[0096] SiO 2 30%

[0097] B 2 o 3 25%

[0098] ZnO 15%

[0099] Al 2 o 3 15%

[0100] MgO 10%

[0101] ZrO 2 2.5%

[0102] Eu 2 o 3 2.5%.

[0103] For the composite functional phase, by weight percentage, it includes the following components:

[0104] Spherical silver powder 50%

[0105] Flake silver powder 48%

[0106] Nano palladium powder 2%.

[0107] For the organic vehicle, by weight percentage, it includes the following components:

[0108] Butyl Carbitol 45%

[0109] Butyl Carbitol Acetate 25%

[0110] Polyurethane resin 25%

[0111] 1,4-Dihydroxysulfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com