Preparation method of triple responsive nanogel and application of triple responsive nanogel

A nanogel, triple-response technology, applied in nanotechnology, preparations for in vivo tests, medical preparations with inactive ingredients, etc., can solve difficult imaging, high cost, complex preparation process of stimuli-responsive nanogels, etc. problem, to achieve good biocompatibility, low hazard effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

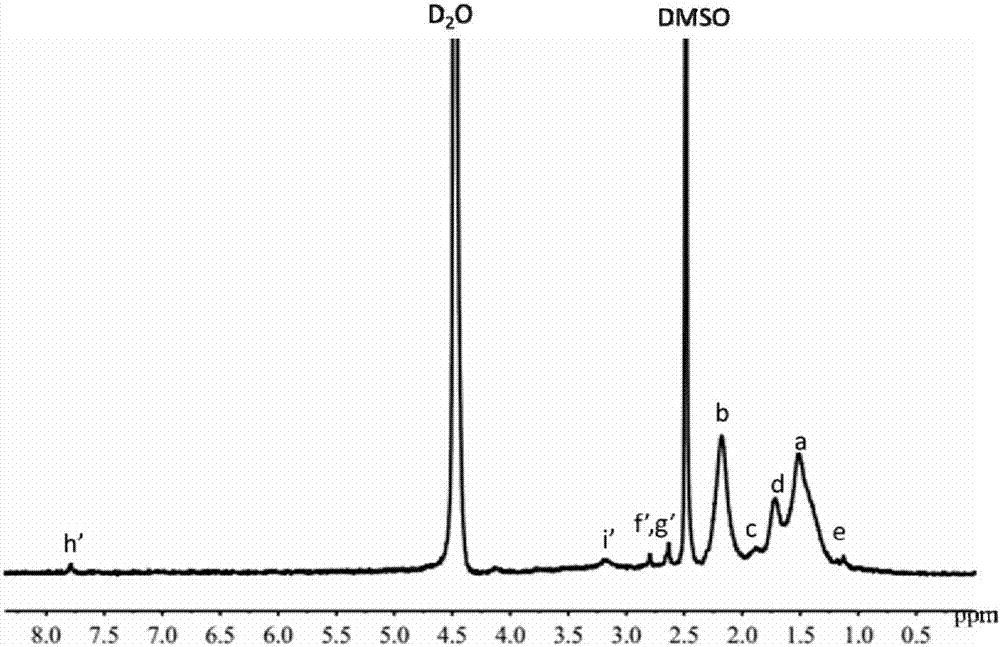

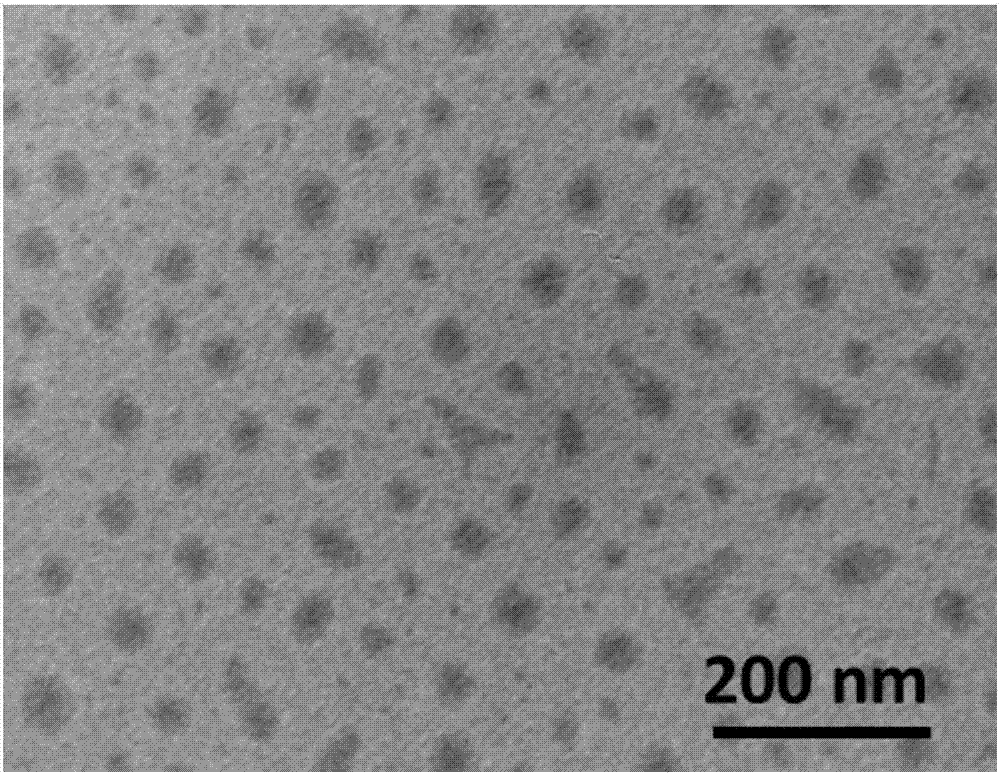

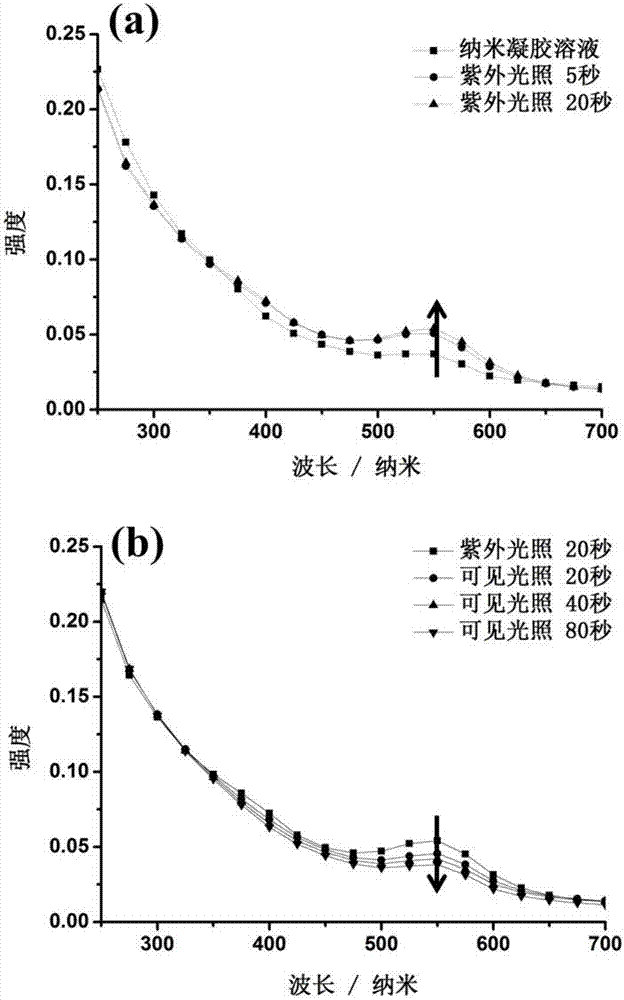

[0023] Follow the steps of the acylation reaction to prepare spiropyranyl methacrylate. Take 300 mg of spiropyran, 24 microliters of methacryloyl chloride and 40 microliters of triethylamine, dissolve them in 20 milliliters of tetrahydrofuran (the filling amount of tetrahydrofuran is 40% of the capacity of the container), and add the mixed solution to the dry In a container, stirred at room temperature for 20 hours, the solution turned orange with precipitation, and then the solution was filtered three times to remove the precipitation, and then the saturated sodium bicarbonate weak alkaline solution and dichloromethane were 1 according to the volume ratio: 3 After mixing, add it to the solution that was filtered to remove the precipitate, and extract it in a separatory funnel until the solution becomes colorless, then extract it three times with deionized water, and add excess magnesium sulfate to the final solution, Stir for 15 hours to remove residual water in the solution....

Embodiment 2

[0032] Follow the steps of the acylation reaction to prepare spiropyranyl methacrylate. Take 400 mg of spiropyran, 55 microliters of methacryloyl chloride and 45 microliters of triethylamine respectively, dissolve them in 15 milliliters of tetrahydrofuran (the charging amount of tetrahydrofuran is 30% of the capacity of the container), and add the mixed solution to the dry In a container, stirred at room temperature for 30 hours, the solution turned orange with precipitation, and then filtered the solution three times to remove the precipitation, then mixed the weakly alkaline solution and dichloromethane at a volume ratio of 1:4, and added into the solution that was filtered to remove the precipitate, and extracted in a separatory funnel until the solution became colorless, then extracted three times with deionized water, added an excessive amount of magnesium sulfate in the finally obtained solution, stirred for 20 hours, and used To remove residual water in the solution, th...

Embodiment 3

[0038] Follow the steps of the acylation reaction to prepare spiropyranyl methacrylate. Take 350 mg of spiropyran, 50 microliters of methacryloyl chloride and 60 microliters of triethylamine, dissolve them in 30 milliliters of tetrahydrofuran (the charging amount of tetrahydrofuran is 60% of the capacity of the container), and add the mixed solution to the dry In a container, stirred at room temperature for 25 hours, the solution turned orange with precipitation, then filtered the solution three times to remove the precipitation, then mixed the weakly alkaline solution and dichloromethane at a volume ratio of 1:2, and added into the solution that was filtered to remove the precipitate, and extracted in a separatory funnel until the solution became colorless, then extracted three times with deionized water, added an excessive amount of magnesium sulfate in the finally obtained solution, stirred for 10 hours, and used To remove residual water in the solution, the solution after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com