Insulating powder coating and its preparation method, application method, lithium battery metal case coated with the insulating powder coating

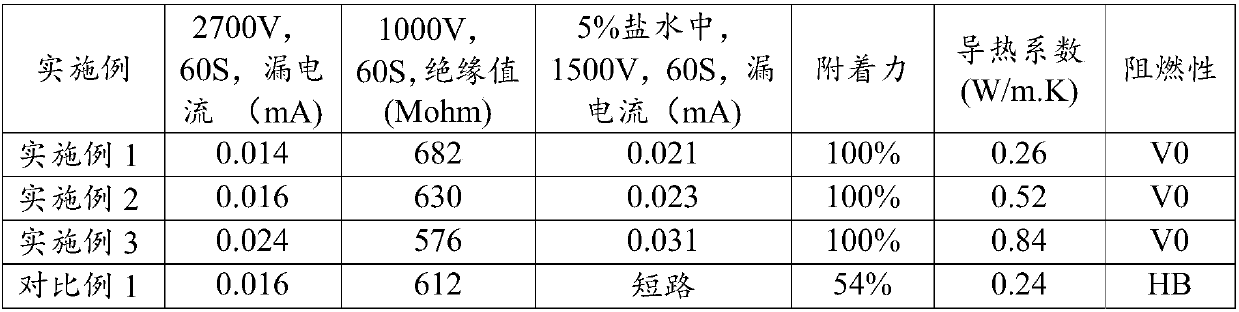

An insulating powder, metal shell technology, applied in powder coatings, battery boxes/jackets, fire retardant coatings, etc., can solve problems such as high cost, leakage or short circuit, air bubbles and gaps, etc., achieve good thermal conductivity, improve reliability, excellent insulating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

1

[0045] The insulating powder coatings of the above-mentioned embodiments are prepared by the following process:

[0046] 1) Pre-mixing: Add solid epoxy resin, silicone resin, latent curing agent, flame retardant, accelerator, filler, pigment, leveling agent, etc. into the pre-mixer according to the ratio in the above table, and stir 10-30 minutes, such as 10, 12, 15, 18, 20, 22, 25, 27, 29 or 30 minutes, until the solid resin is pulverized to form a preliminary uniform powder mixture.

[0047] 2) Melt mixing: Add the pre-mixed powder mixture into the twin-screw extruder, the extrusion temperature is 80-150 degrees, such as 80, 90, 100, 110, 120, 130, 140 or 150 degrees, and the residence time is 10-30 seconds, such as 10, 15, 17, 20, 22, 25, 27 or 30 seconds. The powder mixture is heated and melted by the twin-screw extruder, gradually mixed evenly, and becomes a uniform liquid mixture after extrusion.

[0048] 3) Coarse pulverization: the liquid mixture is compres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com