Phase change composite material and preparation method thereof

A technology of phase-change composite materials and core materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of cumbersome modification process, secondary pollution, long cycle, etc., and achieve simple modification process and short cycle , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides a kind of preparation method of phase change composite material, it comprises the following steps:

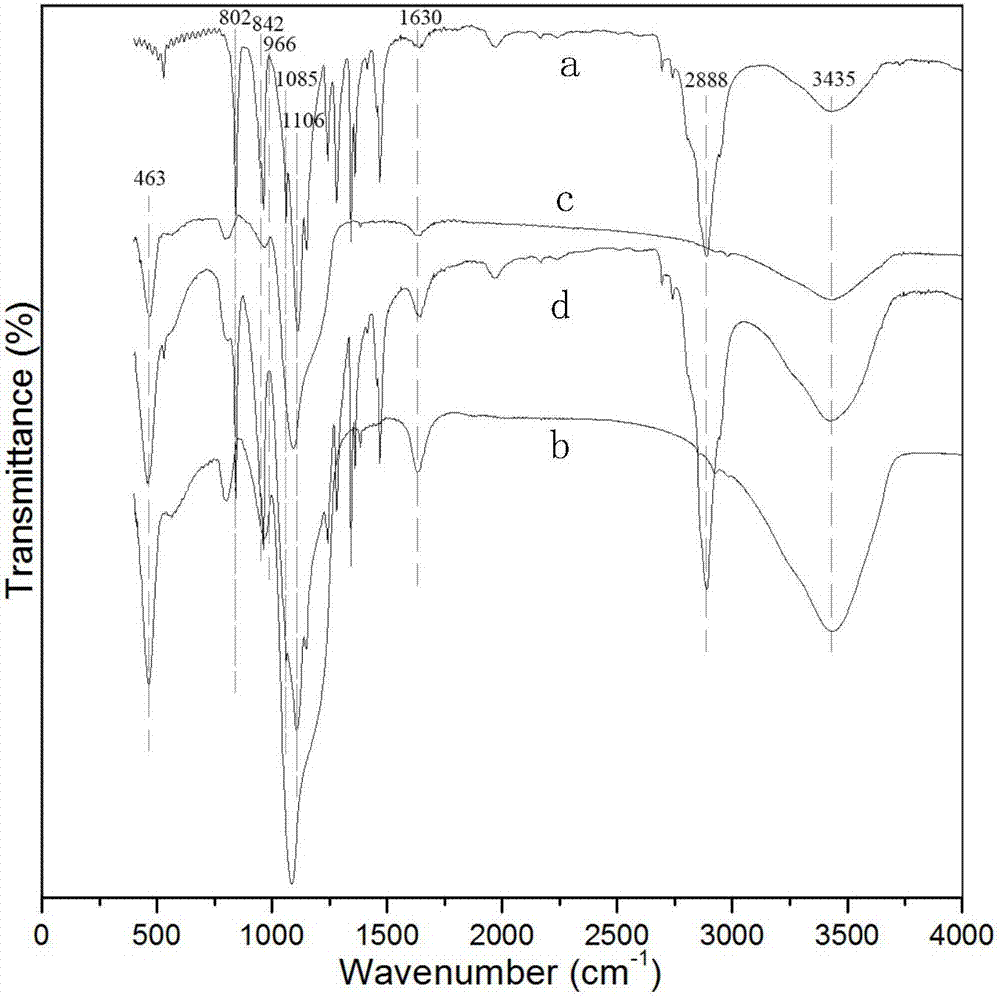

[0038] S1, providing mesoporous silica, wherein the mesoporous silica includes a plurality of channels;

[0039] S2, modifying the mesoporous silica with dopamine, so that dopamine is attached to the channel of the mesoporous silica; and

[0040] S3, immersing the dopamine-modified mesoporous silica in a polyethylene glycol solution, so that the polyethylene glycol is immobilized in the channel of the mesoporous silica as a core material to obtain a phase change composite material, wherein The polyethylene glycol forms a hydrogen bond with the amino group in the dopamine and the catechol functional group to realize the tight combination with the mesoporous silicon dioxide.

[0041] In step S1, the mesoporous silica can be self-made or purchased from the market. The channels of the mesoporous silica are used to load subsequent dopamine and...

Embodiment 1

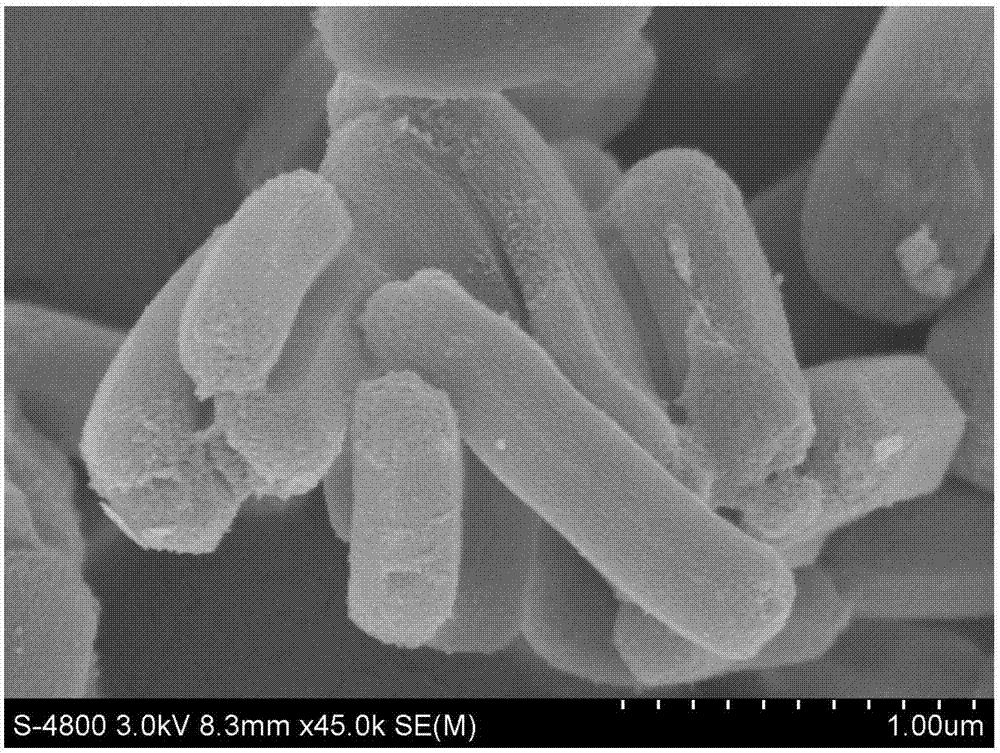

[0069] (1) Preparation of mesoporous silica

[0070] Dissolve 544mg of tannic acid in 100mL of absolute ethanol at room temperature, add 50mL of concentrated ammonia water, stir rapidly for 1min, then add 0.6mL tetraethyl orthosilicate, stir rapidly at room temperature for 2h. After the reaction was completed, the suspension was centrifuged and washed with distilled water for several times to obtain mesoporous silica TAMS.

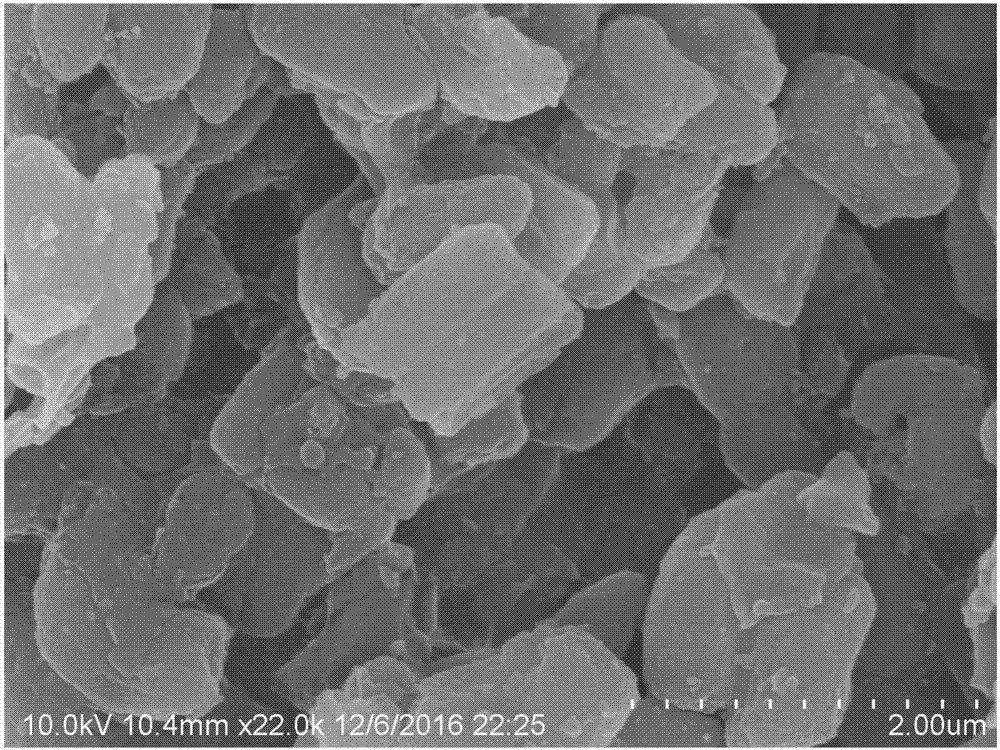

[0071] (2) Preparation of dopamine-modified mesoporous silica

[0072] Dissolve 0.045g of dopamine in 45mL of newly prepared pH 8.5 phosphate buffer solution, then quickly add 0.225g of mesoporous silica TAMS, stir at room temperature for 3h, centrifuge and dehydrate the suspension, wash with distilled water twice, and vacuum at 40°C After drying for 24 hours, dopamine-modified mesoporous silica Dop-TAMS was obtained.

[0073] (3) Preparation of phase change composite materials

[0074] Put 50mg of Dop-TAMS in a beaker, add 15mL of 8g / L PEG ethanol solu...

Embodiment 2

[0076] (1) Preparation of mesoporous silica

[0077] Dissolve 544mg of tannic acid in 100mL of absolute ethanol at room temperature, add 50mL of concentrated ammonia water, stir rapidly for 1min, then add 0.6mL tetraethyl orthosilicate, stir rapidly at room temperature for 2h. After the reaction was completed, the suspension was centrifuged and washed with distilled water for several times to obtain mesoporous silica TAMS.

[0078] (2) Preparation of dopamine-modified mesoporous silica

[0079] Dissolve 0.045g of dopamine in 45mL of newly prepared pH 8.5 phosphate buffer solution, then quickly add 0.225g of mesoporous silica TAMS, stir at room temperature for 3h, centrifuge and dehydrate the suspension, wash with distilled water twice, and vacuum at 40°C After drying for 24 hours, dopamine-modified mesoporous silica Dop-TAMS was obtained.

[0080] (3) Preparation of phase change composite materials

[0081] Put 50mg of Dop-TAMS in a beaker, add 15mL 8g / L PEG ethanol solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting enthalpy | aaaaa | aaaaa |

| Melting enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com