Self-association fracturing fluid system with water control function and preparation method thereof

A technology of self-association and fracturing fluid, which is applied in the direction of drilling compositions, chemical instruments and methods, and can solve problems such as oil production reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

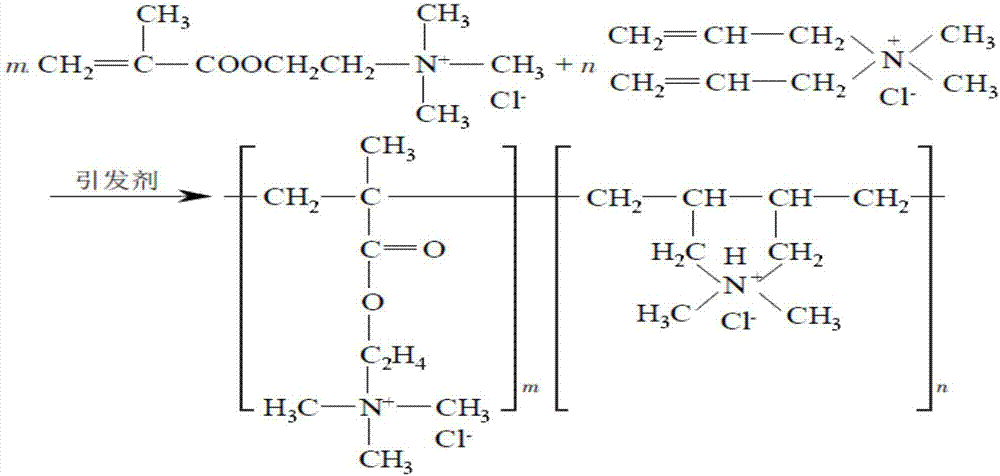

Method used

Image

Examples

Embodiment 1

[0028] Take by weighing 20gDMDAAC (purity is 65%) and 20gDMC (purity is 78%) and join in the deionized water of 60g successively, stir and mix evenly, obtain mixed reaction solution; Continue to add the persulfuric acid of each 0.02g in the mixed reaction solution under room temperature Ammonium and sodium bisulfite were reacted for 30 minutes under the protection of a nitrogen atmosphere, and finally a white colloid was obtained, which was dried and crushed at 65-70°C, which was a cationic polymer; the average molecular weight of the cationic polymer was 1.5 million;

[0029] When using on-site, add 0.4g cationic polymer to every 100ml of water, then add 0.3g dodecylbenzenesulfonic acid, stir for 2 minutes to form a jelly, the viscosity of the jelly is 236mPa.S; continue to add 0.05g over Ammonium sulfate, mixed evenly, can obtain a self-associated fracturing fluid system with water control function.

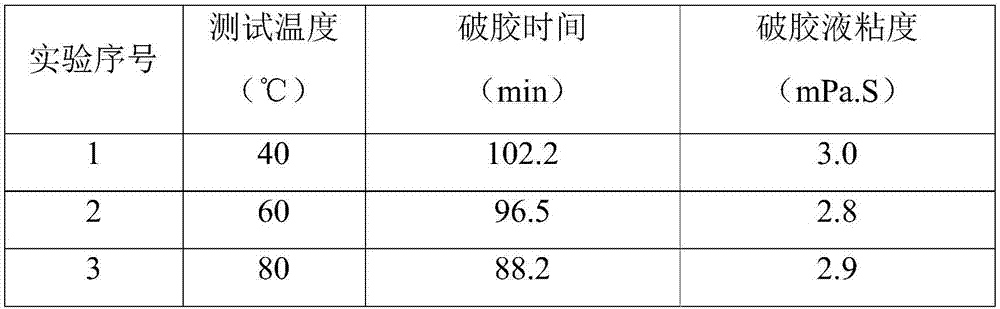

[0030] The fracturing fluid system prepared in Example 1 was subjected to ...

Embodiment 2

[0034] Take by weighing 20gDMDAAC (purity is 65%) and 20gDMC (purity is 78%) and join in the deionized water of 60g successively, stir and mix evenly, obtain mixed reaction solution; Continue to add the persulfuric acid of each 0.02g in the mixed reaction solution under room temperature Ammonium, sodium bisulfite and 4g of ammonium bicarbonate were reacted for 30 minutes under the protection of a nitrogen atmosphere, and finally a white colloid was obtained, which was dried and pulverized at 65-70 ° C, which was a cationic polymer; the cationic polymer The average molecular weight is 2 million;

[0035]When using on-site, add 0.4g cationic polymer to every 100ml of water, then add 0.3g dodecylbenzenesulfonic acid, stir for 2 minutes to form a jelly, the viscosity of the jelly is 240mPa.S; continue to add 0.05g over Ammonium sulfate, mixed evenly, can obtain a self-associated fracturing fluid system with water control function.

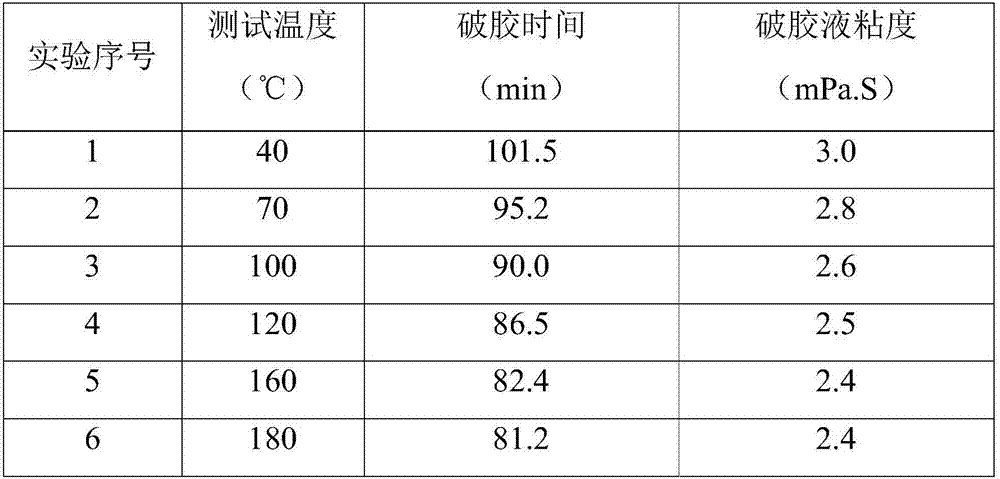

[0036] The fracturing fluid system prepared in ...

Embodiment 3

[0040] Take by weighing 15gDMDAAC (purity is 65%) and 15gDMC (purity is 78%) and join in the deionized water of 70g successively, stir and mix uniformly, obtain mixed reaction solution; Continue to add each 0.01g persulfuric acid in mixed reaction solution under room temperature Ammonium, sodium bisulfite and 4g of ammonium bicarbonate were reacted for 30 minutes under the protection of a nitrogen atmosphere, and finally a white colloid was obtained, which was dried and pulverized at 65-70 ° C, which was a cationic polymer; the cationic polymer The average molecular weight is 2.6 million;

[0041] When using on-site, add 0.4g cationic polymer to every 100ml of water, then add 0.3g dodecylbenzenesulfonic acid, stir for 2 minutes to form a gel, and the viscosity of the gel is 250mPa.S; continue to add 0.05g over Ammonium sulfate, mixed evenly, can obtain a self-associated fracturing fluid system with water control function.

[0042] The fracturing fluid system prepared in Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com