Preparation method and application of low-cost hollow carbon sphere-based oxygen reducing catalyst

A hollow carbon sphere and catalyst technology, applied in the field of environmental engineering, can solve the problems of inability to fundamentally prevent agglomeration, complex synthesis procedures, difficult industrial production, etc., and achieve the effects of easy operation, simple preparation method and mild modification conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

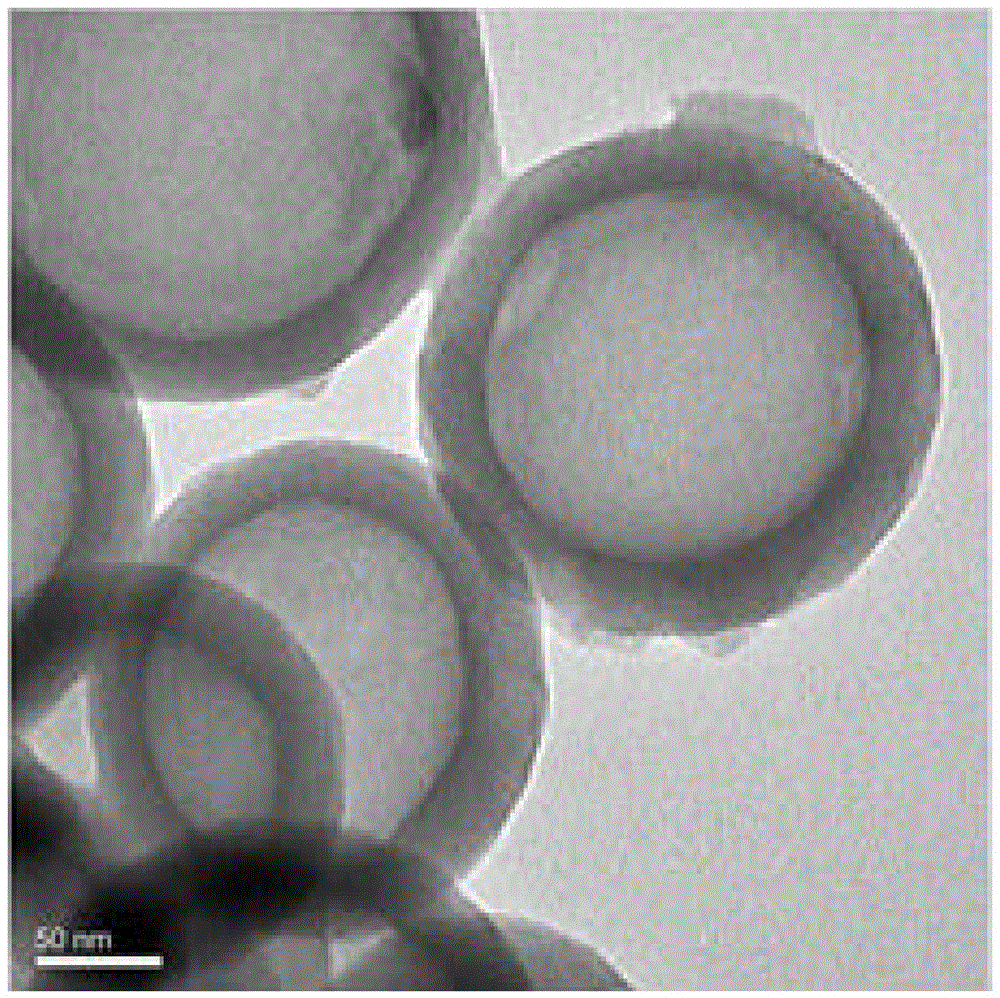

[0036] Embodiment 1: the preparation of hollow carbon sphere oxygen reduction catalyst The preparation method of hollow carbon sphere oxygen reduction catalyst comprises the following steps:

[0037] ① Weigh 66mg template agent Pluronic P123 and 110mg sodium oleate to prepare aqueous solution A. Then take appropriate 277mg 2,4-dihydroxybenzoic acid and be mixed with the aqueous solution that concentration is 15mmol / L, then take 105mg hexamethylenetetramine and dissolve in 2,4-dihydroxybenzoic acid solution, obtain solution B, wherein The concentration of hexamethylenetetramine is 6.25mmol / L; solution B is added into solution A under stirring condition, and stirring is continued for 10min to obtain solution C. The solution C was sealed and placed in an oven, and the hydrothermal reaction was carried out under the pressure of 2 atm and the temperature of 160° C., and the reaction time was 2 hours. The reacted product was cooled to room temperature, centrifuged with ultrapure wa...

Embodiment 2

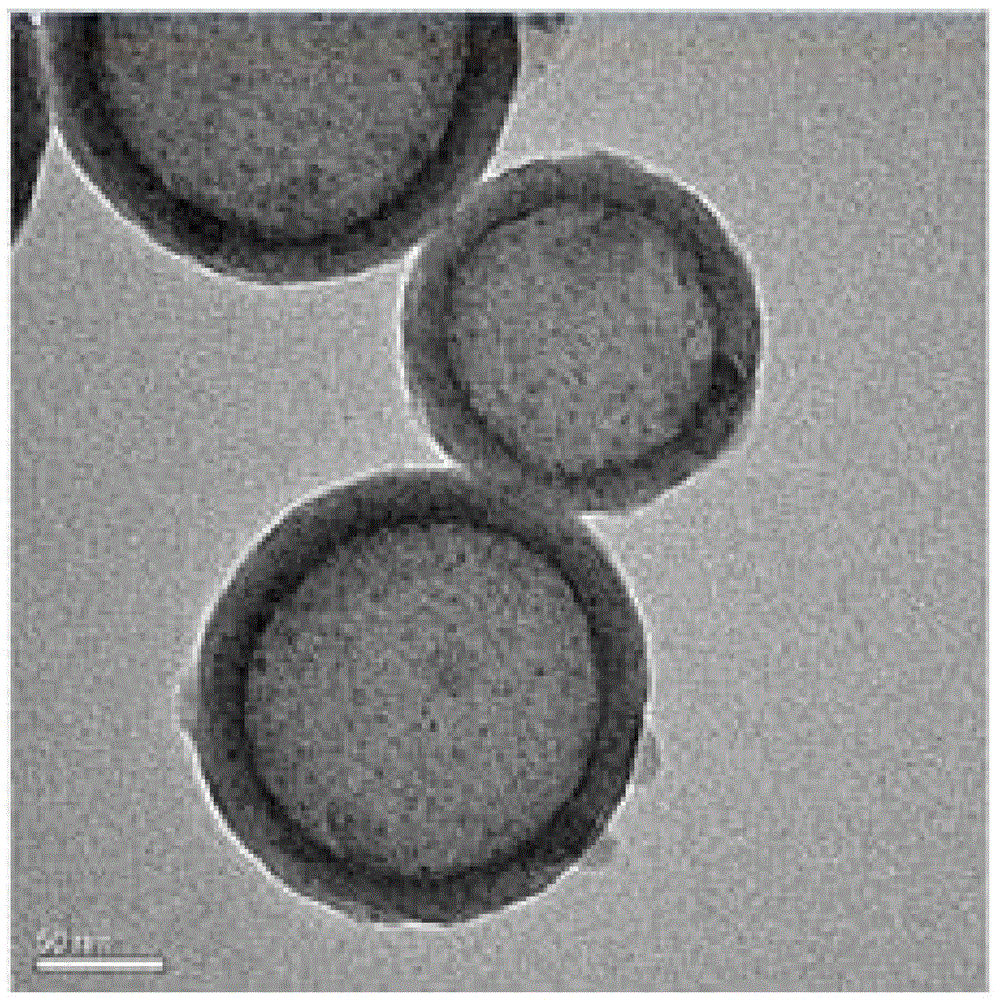

[0043] Embodiment 2: Preparation of hollow carbon sphere oxygen reduction catalyst

[0044] The difference from Example 1 is that the calcination temperature in step ② is 900°C.

Embodiment 3

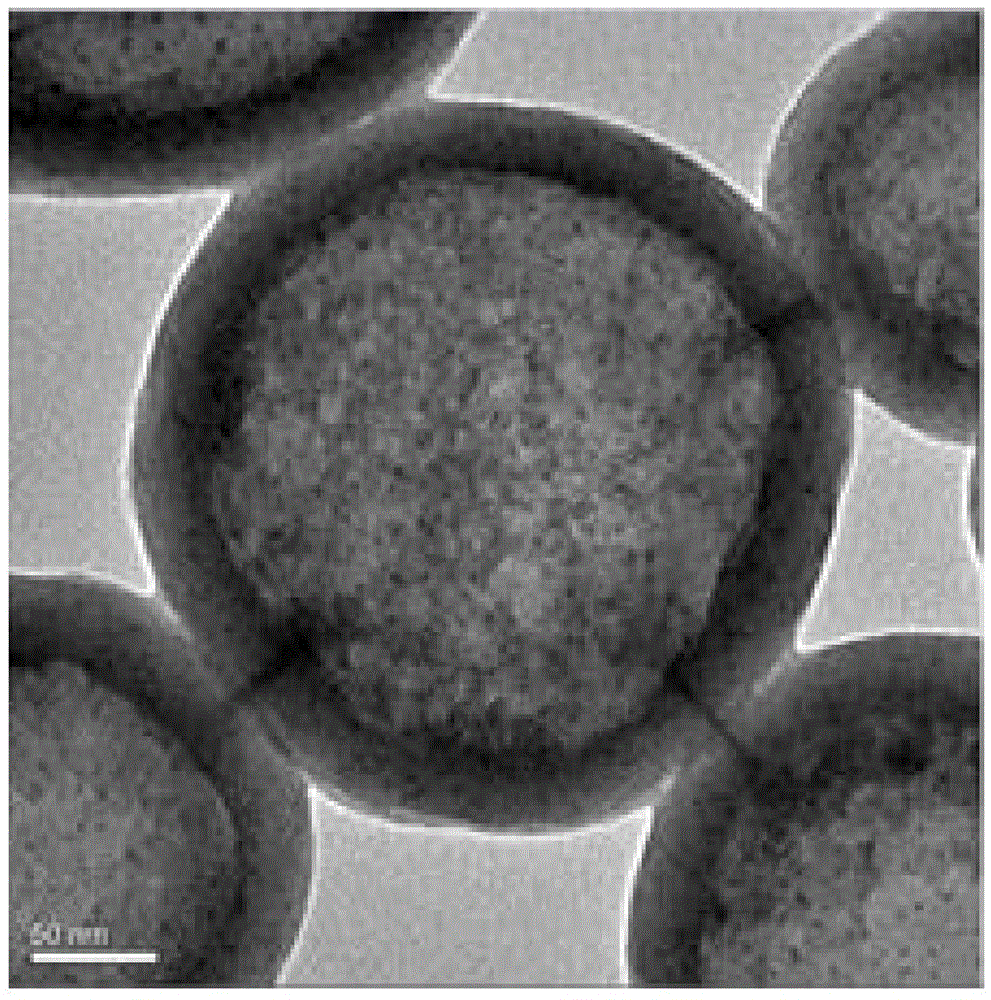

[0045] Embodiment 3: Preparation of hollow carbon spheres supporting transition metal Fe oxides

[0046] Different from Example 1, the preparation method of hollow carbon spheres loaded with transition metal Fe oxides comprises the following steps:

[0047] ① Weigh 66mg template agent Pluronic P123, 110mg sodium oleate and 72.72mg ferric nitrate nonahydrate to prepare aqueous solution A. Then take an appropriate amount of 277mg 2,4-dihydroxybenzoic acid to prepare an aqueous solution with a concentration of 15mmol / L, and then dissolve 105mg of hexamethylenetetramine in the 2,4-dihydroxybenzoic acid solution to obtain solution B, in which The concentration of methylenetetramine is 6.25mmol / L; solution B is added into solution A under stirring condition, and stirring is continued for 10min to obtain solution C. The solution C was sealed and placed in an oven, and the hydrothermal reaction was carried out under the pressure of 2 atm and the temperature of 160° C., and the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com