Proton conductor material, preparation method and application thereof, and intermediate temperature fuel cell

A proton conductor, fuel cell technology, applied in fuel cells, chemical instruments and methods, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

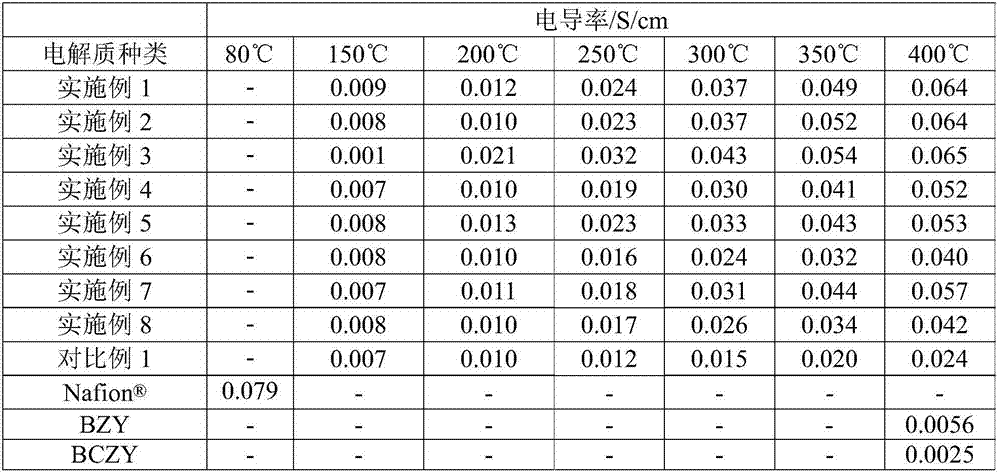

Examples

preparation example Construction

[0029] In the method for preparing a proton conductor material described in the second aspect of the present invention, the chemical formula of the proton conductor material is preferably the same as that of the proton conductor material described in the aforementioned first aspect, and the present invention no longer treats protons in the second aspect The preferred conditions of the conductor material will be described in detail, which should not be understood by those skilled in the art as limiting the present invention.

[0030] Preferably, in step (1), the roasting conditions include: the temperature is 250-600° C., and the time is 4-30 hours.

[0031] The oxide of A in the present invention means a binary compound formed by metal A element and oxygen, and the oxide of B means a binary compound formed by metal B element and oxygen.

[0032] The oxide of A is preferably Y 2 o 3 、TiO 2 , Nb 2 o 5 、 Ta 2 o 5 、MoO 2 and WO 3 .

[0033] The oxide of B is preferably A...

Embodiment 1

[0049] Embodiment 1: preparation (NH 4 ) 2 Mo 0.8 Ge 0.2 P 4 o 13

[0050] According to the stoichiometric ratio, ammonium polyphosphate, MoO 2 and GeO 2 The powders were thoroughly mixed with a mortar and calcined at 450°C for 10h in an ammonia atmosphere. Then the ammonia gas was switched to argon, and the temperature was lowered to 25°C at a cooling rate of 5°C / min. Utilize X-ray diffractometer and neutron diffraction (25 DEG C, the same below) to characterize the phase of product, know from XRD pattern, product (NH 4 ) 2 Mo 0.8 Ge 0.2 P 4 o 13 is a pure triclinic phase, space group:

[0051] According to the results of neutron diffraction, the product (NH 4 ) 2 Mo 0.8 Ge 0.2 P 4 o 13 tetraphosphate unit cells (P 4 o 13 6- ) are arranged along the [011] direction, and four tetraphosphate units are bonded with Mo / Ge atoms to form an octahedral structure, forming a [(Mo 0.8 Ge 0.2 )P 4 o 13 2- ] n layer, these [(Mo 0.8 Ge 0.2 )P 4 o 13 2- ]...

Embodiment 2

[0055] Embodiment 2: preparation (NH 4 ) 2 W 0.76 Ge 0.24 P 4 o 13

[0056] According to the stoichiometric ratio, ammonium polyphosphate, WO 3 and GeO 2 The powders were thoroughly mixed with a mortar and calcined at 400°C for 15h in an ammonia atmosphere. Then the ammonia gas was switched to argon, and the temperature was lowered to 30°C at a cooling rate of 10°C / min. Utilize X-ray diffractometer and neutron diffraction to characterize the phase of product, know from XRD pattern, product (NH 4 ) 2 W 0.76 Ge 0.24 P 4 o 13 is a pure triclinic phase, space group:

[0057] The neutron diffraction results are similar to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com