Bismuthyl bromide/bismuth molybdate heterojunction photocatalyst as well as preparation method and application thereof

A technology of bismuth oxybromide and photocatalyst, which is applied in the field of photocatalytic materials, can solve the problems of low quantum yield and visible light absorption utilization rate, etc., and achieves the effects of great development and application prospects, good degradation effect, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

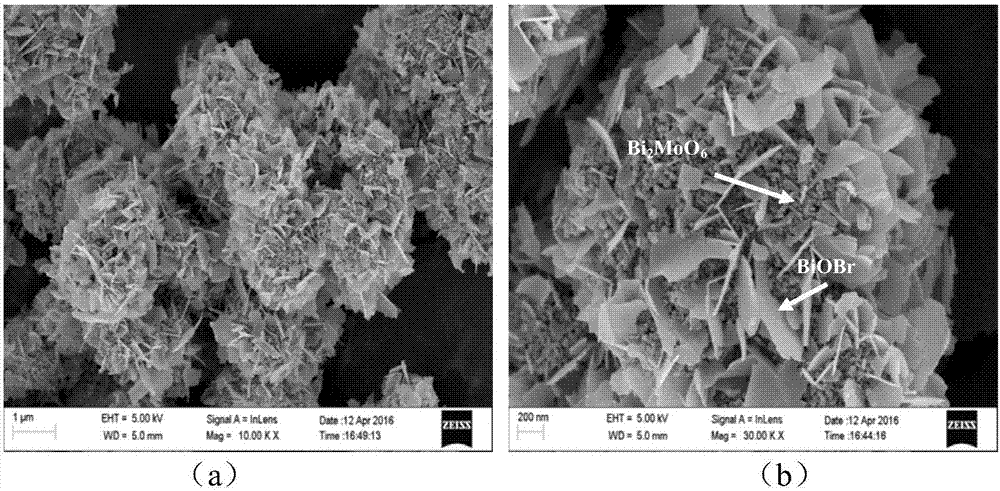

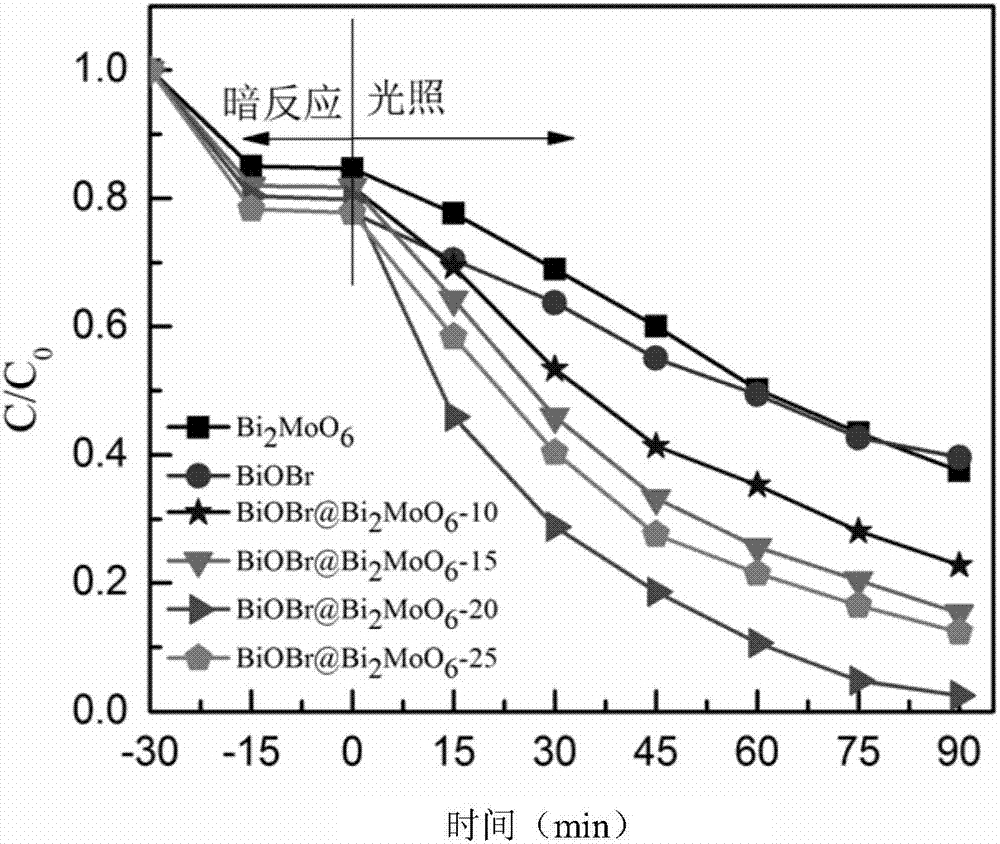

[0033] (1) Preparation of Bi by solvothermal method 2 MoO 6 Microspheres: 2mmol Bi(NO 3 ) 3 ·5H 2 O and 1 mmol Na 2 MoO 4 2H 2 Dissolve O in 5mL of ethylene glycol respectively, mix the two evenly under magnetic stirring at a speed of 500r / min, and slowly add 20mL of absolute ethanol, stir at room temperature for 30min at a speed of 500r / min, pour Put it into a 50mL closed reaction kettle, react at 160°C for 12h, wash the obtained product three times with absolute ethanol and deionized water, and dry it in a vacuum oven at 60°C for 12h to obtain Bi 2 MoO 6 Microspheres;

[0034] (2) Take 1g Bi from step (1) 2 MoO 6 Ultrasonic dispersion in 10mL of deionized water under the condition of P=100W to obtain a dispersion; 0.1591g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 20mL of ethylene glycol and added to the dispersion, and mixed to obtain a mixed dispersion;

[0035] (3) Dissolve 0.1195g CTAB in 20mL ethylene glycol to obtain a CTAB ethylene glycol solution; slowly add ...

Embodiment 2

[0037] (1) Preparation of Bi by solvothermal method 2 MoO 6 Microspheres: 2mmol Bi(NO 3 ) 3 ·5H 2 O and 1 mmol Na 2 MoO 4 2H 2 Dissolve O in 5mL of ethylene glycol respectively, mix the two evenly under magnetic stirring at a speed of 500r / min, and slowly add 20mL of absolute ethanol, stir at room temperature for 30min at a speed of 500r / min, pour Put it into a 50mL closed reaction kettle, react at 160°C for 12h, wash the obtained product three times with absolute ethanol and deionized water, and dry it in a vacuum oven at 60°C for 12h to obtain Bi 2 MoO 6 Microspheres;

[0038] (2) Take 1g Bi from step (1) 2 MoO 6 Ultrasonic dispersion in 10mL of deionized water under the condition of P=100W to obtain a dispersion; 0.2387g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 20mL of ethylene glycol and added to the dispersion, and mixed to obtain a mixed dispersion;

[0039] (3) Dissolve 0.1793g CTAB in 20mL ethylene glycol to obtain a CTAB ethylene glycol solution; slowly add ...

Embodiment 3

[0041] (1) Preparation of Bi by solvothermal method 2 MoO 6 Microspheres: 2mmol Bi(NO 3 ) 3 ·5H 2 O and 1 mmol Na 2 MoO 4 2H 2 O was respectively dissolved in 5 mL of ethylene glycol, and the two were mixed evenly under magnetic stirring at a speed of 500 r / min, and 20 mL of dehydrated ethanol was slowly added, and after stirring for 30 min at a speed of 500 r / min at room temperature, Pour it into a 50mL closed reaction kettle, react at 160°C for 12h, wash the obtained product three times with absolute ethanol and deionized water, and dry it in a vacuum oven at 60°C for 12h to obtain Bi 2 MoO 6 Microspheres;

[0042] (2) Take 1g Bi from step (1) 2 MoO 6 Ultrasonic dispersion in 10mL of deionized water under P=100W conditions, to obtain a dispersion; 0.3182g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 20mL of ethylene glycol and added to the dispersion, and mixed evenly to obtain a mixed dispersion;

[0043] (3) Dissolve 0.2391g CTAB in 20mL ethylene glycol to obtain a C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com